Analysis of the digital image of the external surface of a tyre and processing of false measurement points

An image and three-dimensional digital technology, applied in image analysis, image data processing, image enhancement, etc., can solve problems such as abnormal tire structure and disappearance of false measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

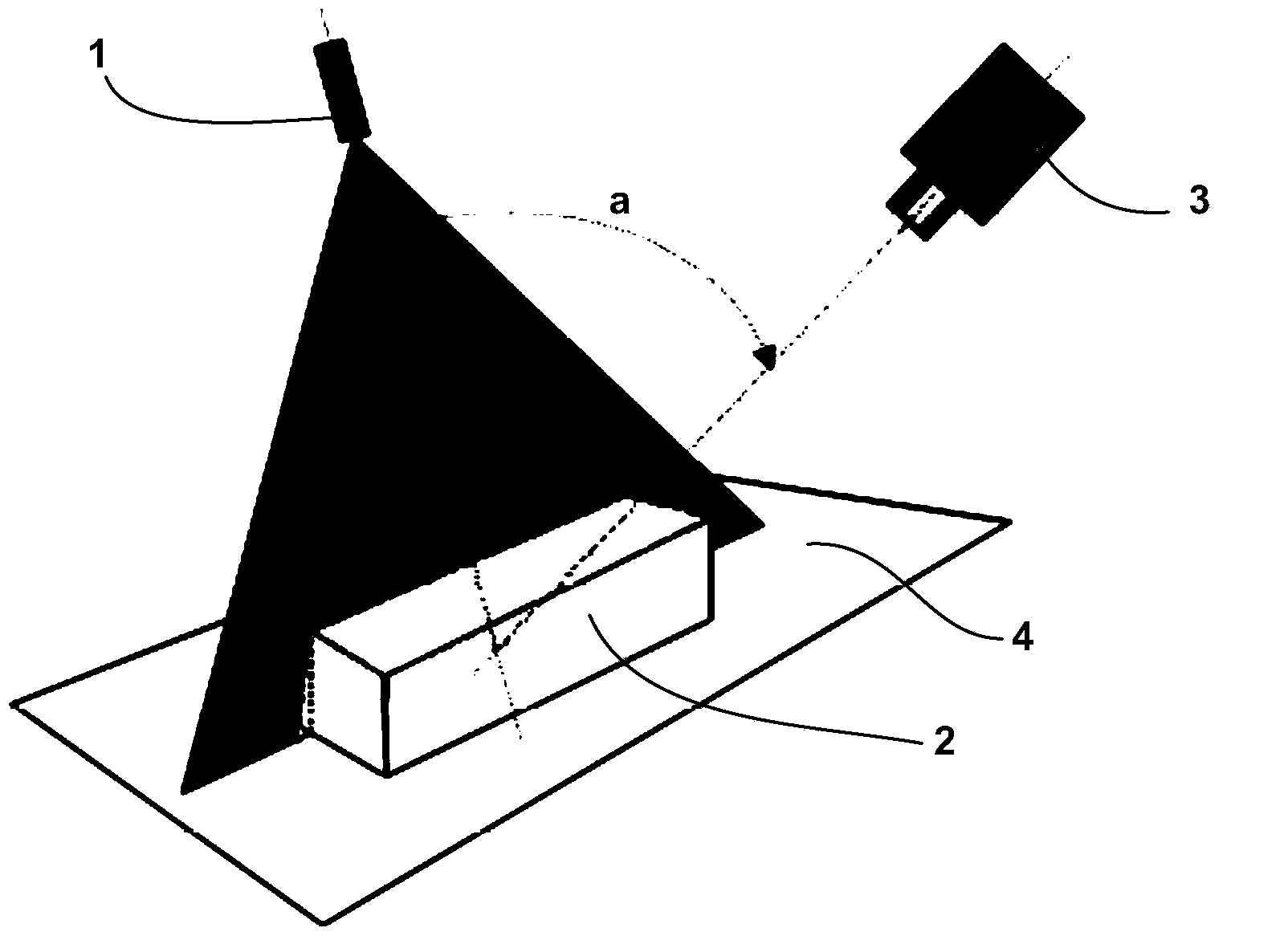

[0028] figure 1 Acquisition of an image of the tire surface is shown. By way of example, this acquisition is performed by means of slit light emitted by the laser 1 and by means of a camera 3 capable of capturing a 2D image of the illuminated surface. The camera is positioned such that its aiming direction forms a given angle with the beam emitted by the laser source. By triangulation, the coordinates of the relief unit 2 relative to the support surface 4 can then be determined. Generally, the slit light is directed in an axial or radial direction perpendicular to the circumferential direction corresponding to the direction of rotation imposed on the tire to capture a complete image of its surface.

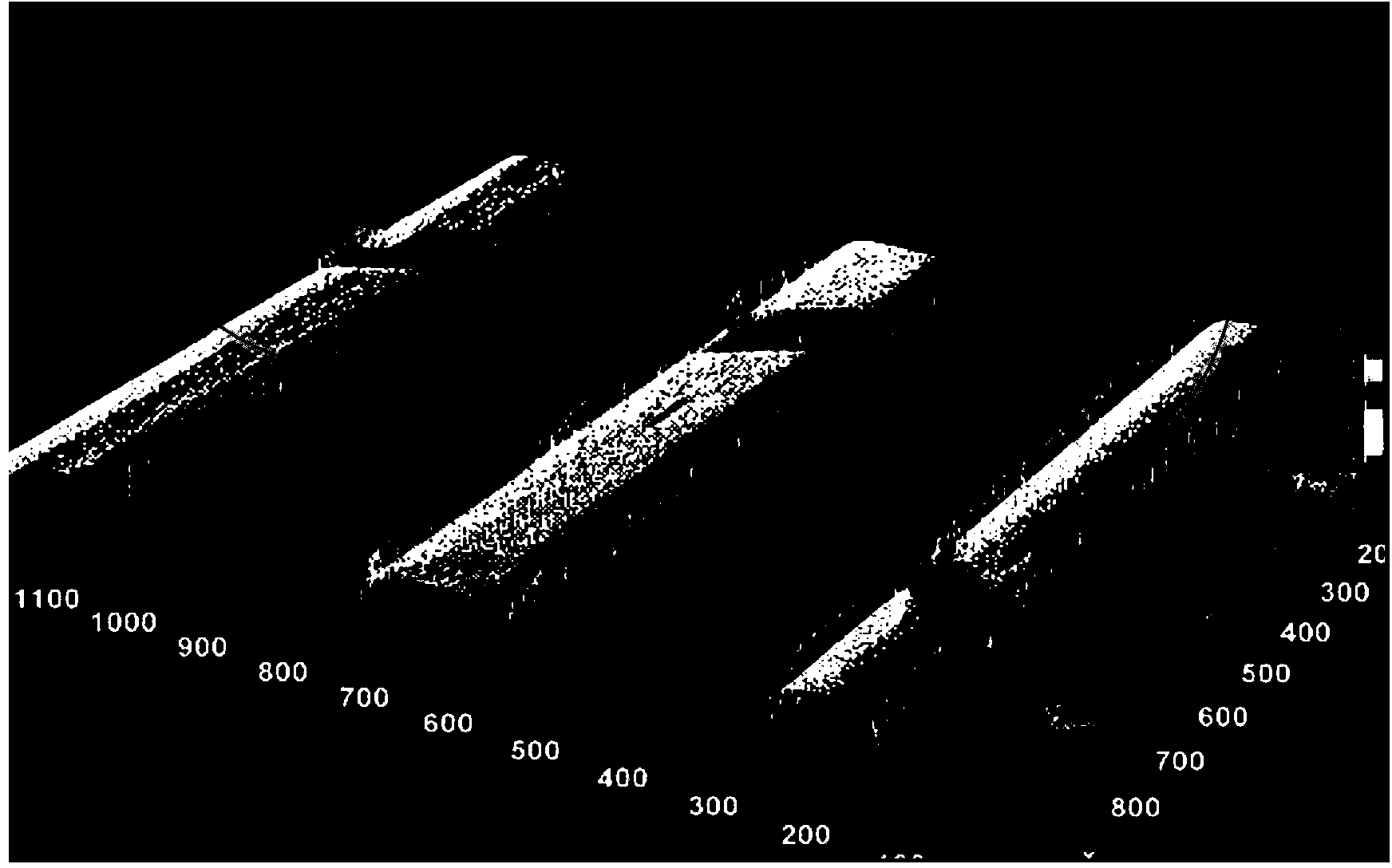

[0029] figure 2 The resulting image from this capture is shown. The presence of false measurement points, denoted FMP, was observed, the presence of false measurement points being especially noticeable on the edges of the tread undulations.

[0030] At each point (x,y) of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com