Freeze tolerant cream and method for producing same

A cream, liquid cream technology, applied in cream preparations, cream substitutes, other dairy products, etc., can solve the problems of unobtainable, smooth whipping cream, etc., and achieve the effect of high freezing resistance and preventing deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

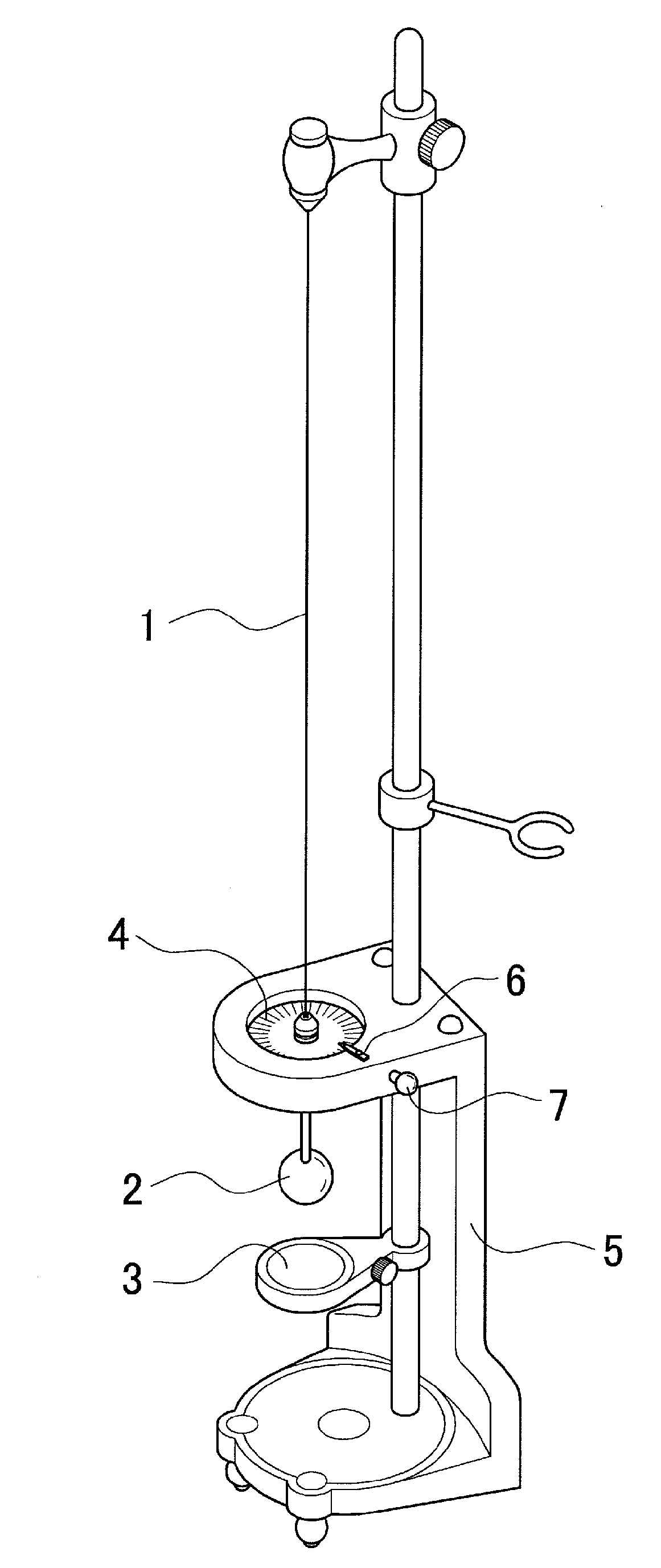

Image

Examples

Embodiment 1

[0047] Weigh 280 kg of main milk with a milk fat content of 35% by weight (hereinafter referred to as raw material cream A), then heat it to 60° C. with a plate heat exchanger, and add the whole amount to a 330 L mixing tank. In the blending and stirring process, the heated raw material cream A is stirred at a speed of 10-20rpm by an anchor mixer attached to the mixing tank, and further passed through a high-speed, high-shear mixer independent of the anchor mixer and attached to the mixing tank. Mixer - a homogeneous mixer, stirring at a speed of 1500-3000rpm. In the blending and stirring process, the anchor type mixer runs unchanged, but the homomixer does not run unchanged, but it takes about 20 minutes to increase the rotation speed from 1500 to 3000rpm in stages, and stir together with the anchor type mixer during this period .

[0048] After blending and stirring, filter the mixture with a 40-mesh filter, and use a homogenizer with a homogenization pressure of 20kgf / cm ...

Embodiment 2

[0053] Liquid cream was obtained by the method similar to Example 1 except having used 280 kg of milk fat content as a raw material (henceforth the raw material cream B) which is 47 weight% of milk main ingredients. The fat content of the obtained liquid cream was 47% by weight, the volume expansion was 8.0% by volume compared with the volume after adding the raw materials in the mixing and stirring step, and the viscosity (Mojonnier method) index at 20° C. was 80. In addition, when the high-speed, high-shear mixer was not used for stirring in the mixing and stirring process, the indicated degree of viscosity (Mojonnier method) at 20°C was the same as Comparative Example 2 described later, which was 45, so the increase rate of the indicated degree was 77.8 %.

Embodiment 3

[0055] Liquid cream was obtained by the method similar to Example 1 except having used 280 kg of milk fat content 40 weight% of milk main raw materials (hereinafter referred to as raw material cream C) as a raw material. The fat content of the obtained liquid cream was 40% by weight, the volume expanded by 7.0% by volume compared with the volume after adding the raw materials in the mixing and stirring step, and the viscosity (Mojonnier method) index at 20° C. was 100. In addition, when the high-speed high-shear mixer was not used for stirring in the blending and stirring process, the indicated degree of viscosity (Mojonnier method) at 20°C was the same as that of Comparative Example 3 described later, which was 60, so the increase rate of the indicated degree was 66.7 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com