Polymer saturated salt water drilling solution suitable for drilling gas storage warehouse

A brine drilling fluid and polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as well wall collapse and block, drilling construction difficulties, etc., to prevent creep, solve pollution resistance and Effects of Inhibitory Capacity Questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] 1. Accurately calculate the internal volume of the wellbore and the effective volume of the surface circulation system, and accurately measure the bentonite content of the drilling fluid.

[0021] 2. Prepare glue with brine (brine density 1.20g / cm 3 ), due to Ca in brine 2+ The content is relatively high (generally 1100mg / l), soda ash should be added to remove calcium, and the following formula is used to determine Na 2 CO 3 The amount of addition, the amount of addition is: Na 2 CO 3 (kg / m 3 )=0.0026×[Ca 2+ ].

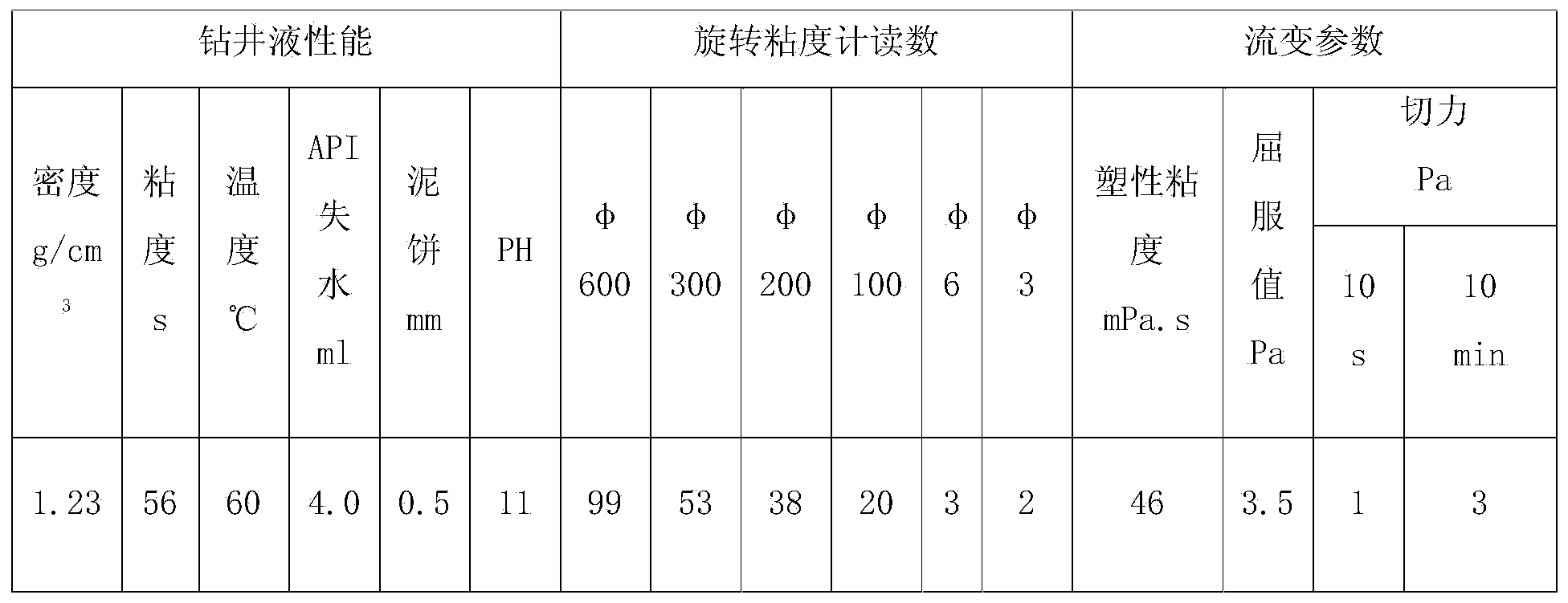

[0022] The formula of the brine glue in parts by mass is: 100 parts of brine, 0.3 part of coating agent for drilling fluid, 1.5 parts of sulfonated phenolic resin, 1 part of high-viscosity sodium carboxymethyl cellulose, 1 part of anti-compound salt Fluid loss reducer, 1.5 parts of anti-slump dilution fluid loss reducer for drilling fluid, 1 part of sulfonated bitumen for drilling fluid, 0.3 part of Na 2 CO 3 , 0.4 parts NaOH, add solid NaCl to saturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com