Plastic oil tank internal welding device

A plastic oil tank and welding device technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of inconvenient production management and maintenance, complicated and cumbersome operation process, and occupy a lot of space, so as to facilitate production management and Maintenance, saving workshop space, and equipment occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application is further described in conjunction with the following examples.

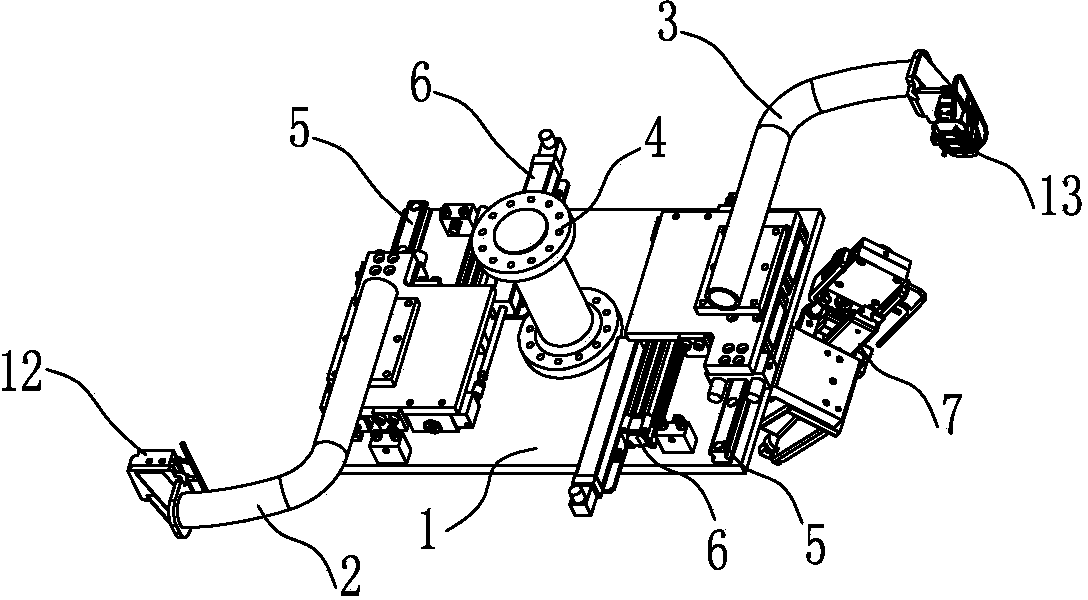

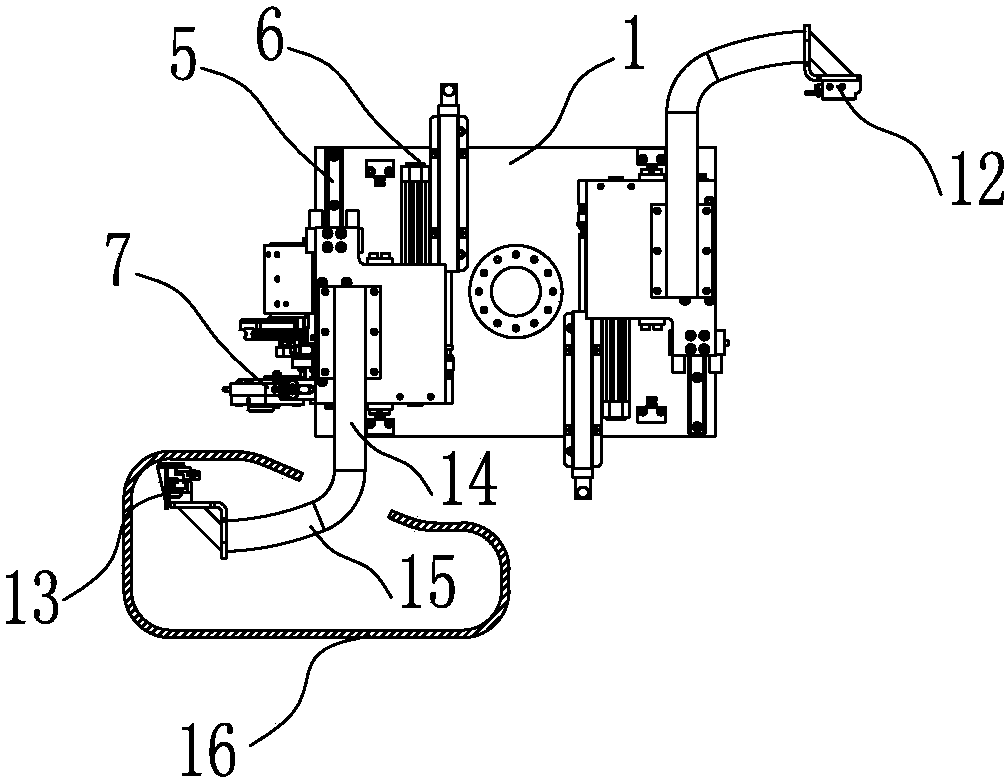

[0038] A welding device inside a plastic fuel tank, such as figure 1 As shown, it includes a support platform 1 and a manipulator set on the support platform 1. At the same time, the welding equipment inside the plastic oil tank also includes a six-axis linkage support arm 4, which is connected to the support platform 1, wherein the six-axis linkage The support arm 4 can move simultaneously on six coordinate axes on the internal welding equipment of the plastic oil tank. The so-called six-axis linkage refers to simultaneous movement or rotation on six coordinate axes (including linear coordinates and rotational coordinates) on the equipment, and can be coordinated simultaneously under the control of the computer numerical control system, which can improve the accuracy of free-form surfaces in space. Machining precision, quality and efficiency. The six axes refer to six coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com