Fixture for metal beam vibration detection

A vibration detection and metal technology, applied in vibration testing, measuring devices, manufacturing tools, etc., can solve problems such as insufficient clamping force, unreasonable design parameters of the fixture structure, easy loosening of the connection between the metal beam and the fixture, etc., to achieve Increased clamping force, compact structure, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

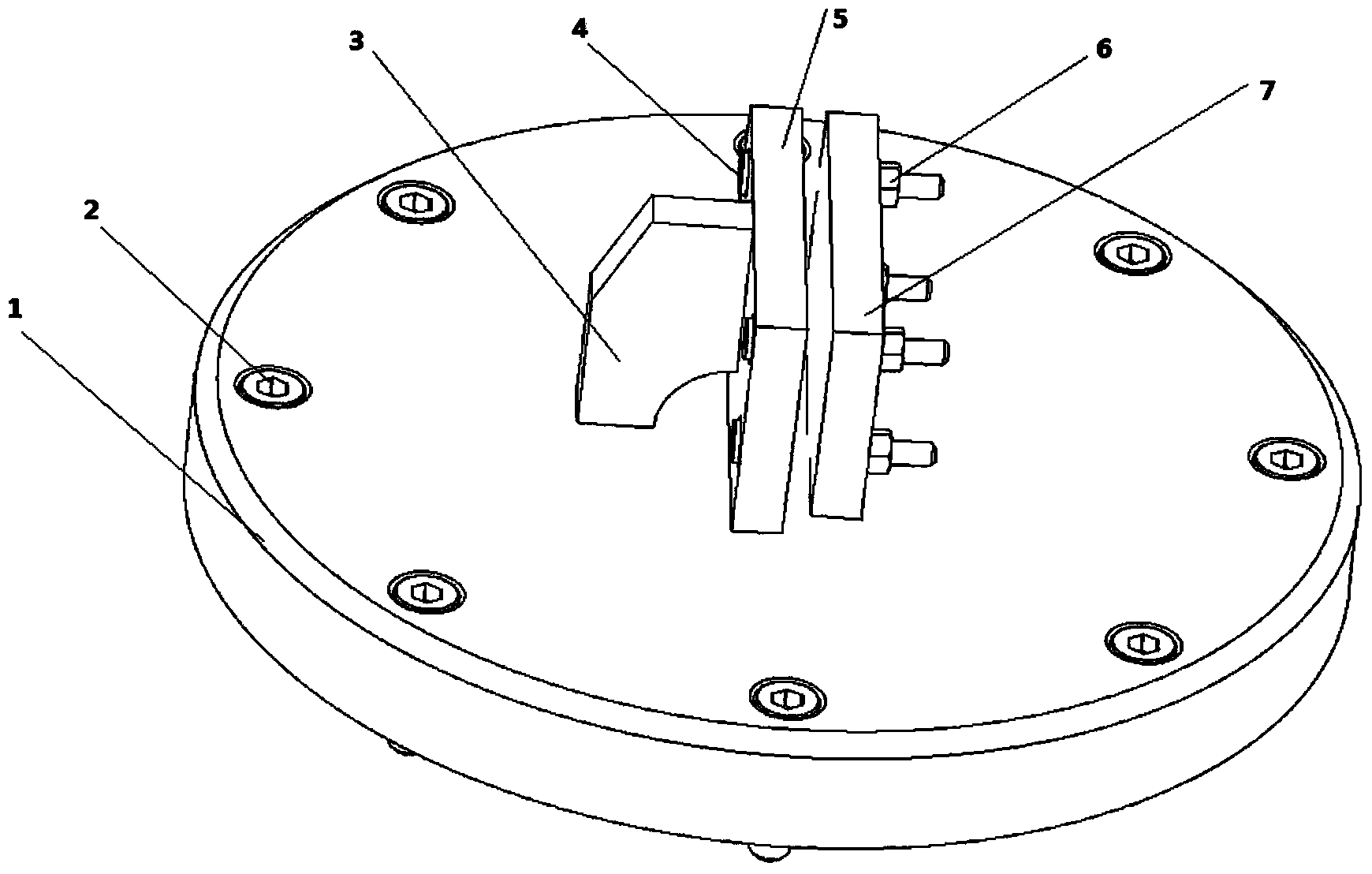

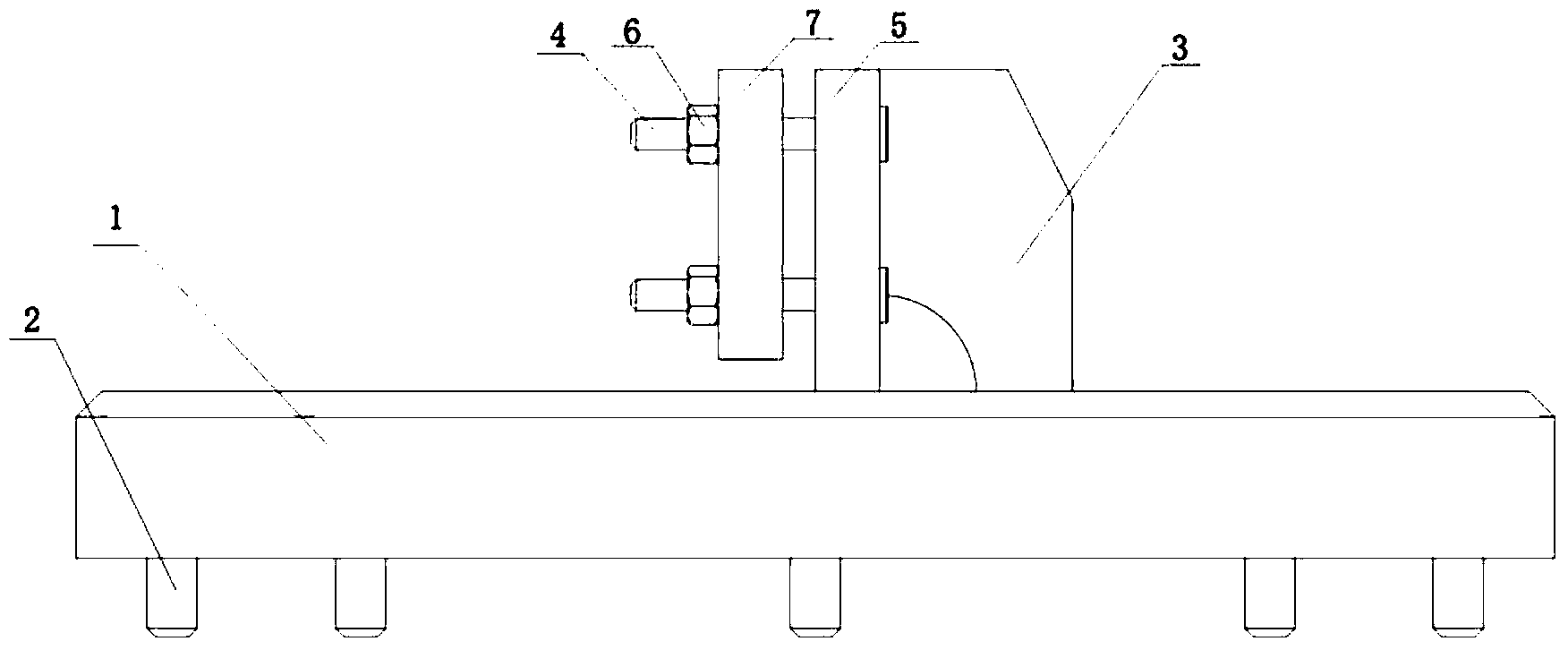

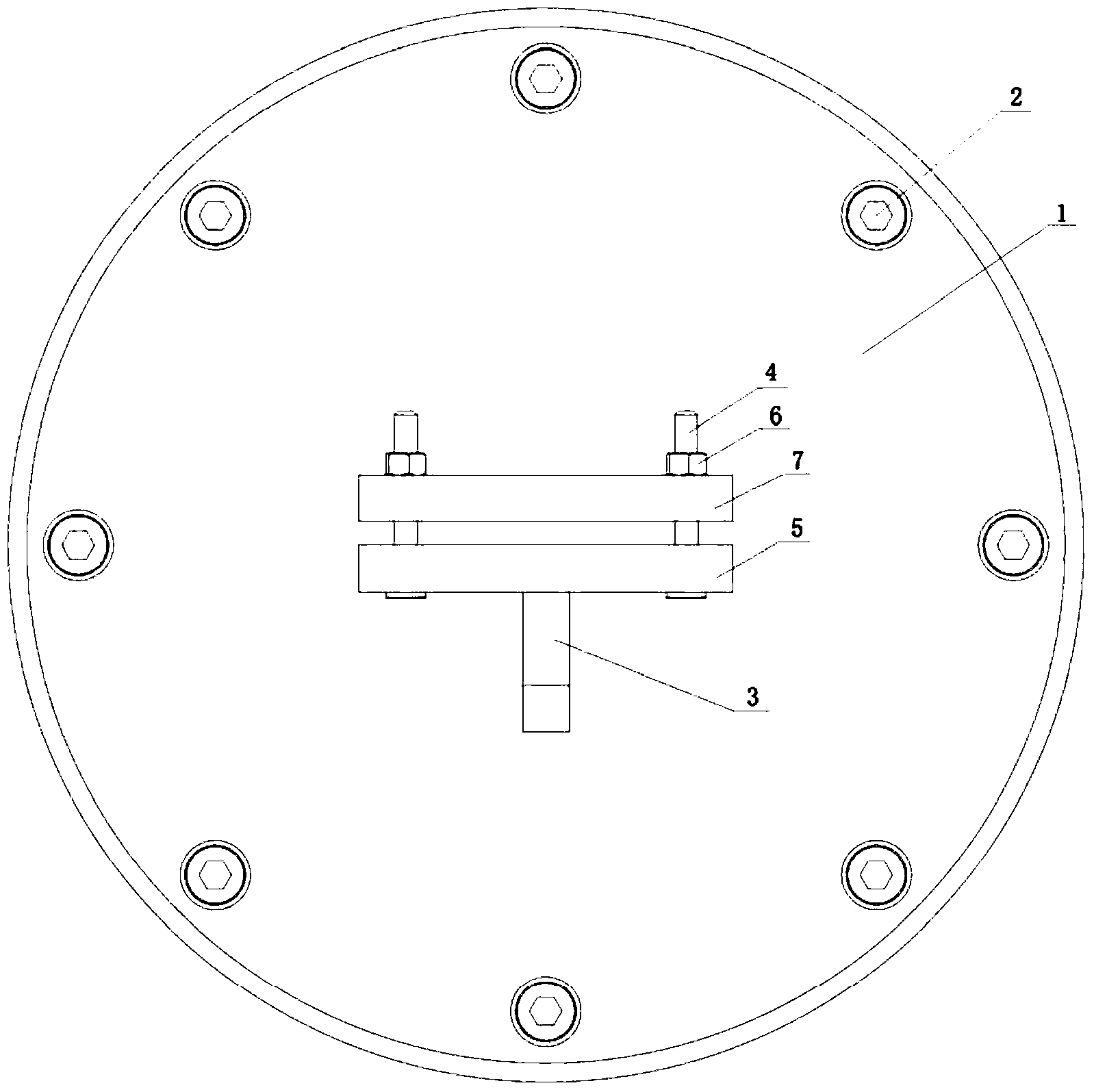

[0034] In this embodiment, the fixture used for metal beam vibration detection is taken as an example, such as Figure 1 to Figure 3 As shown, the fixture for metal beam vibration detection provided by the embodiment of the present invention includes: a base 1 , screws 2 , stiffening plates 3 , fastening bolts 4 , vertical plates 5 , nuts 6 , and baffles 7 .

[0035] The base 1 is provided with eight through countersunk light holes, and the base 1 is fixed on the vibrating table by screws 2, and elastic gaskets are installed on the screws 2, so that the connection between the base 1 and the vibrating table is tighter, improving the The overall rigidity of the structure; the upper edge of the base 1 is chamfered to prevent the skin from being scratched during installation and maintenance.

[0036] The vertical plate 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com