Rapidly-clamping clamp

A fast and packaged technology, applied in the direction of manufacturing tools, gear tooth manufacturing devices, gear teeth, etc., can solve the problems that affect the processing accuracy and quality of products, the difficulty of ensuring coaxiality, and the poor fast clamping performance of fixtures, etc., to overcome Defects of traditional structure, guaranteed processing accuracy and quality, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

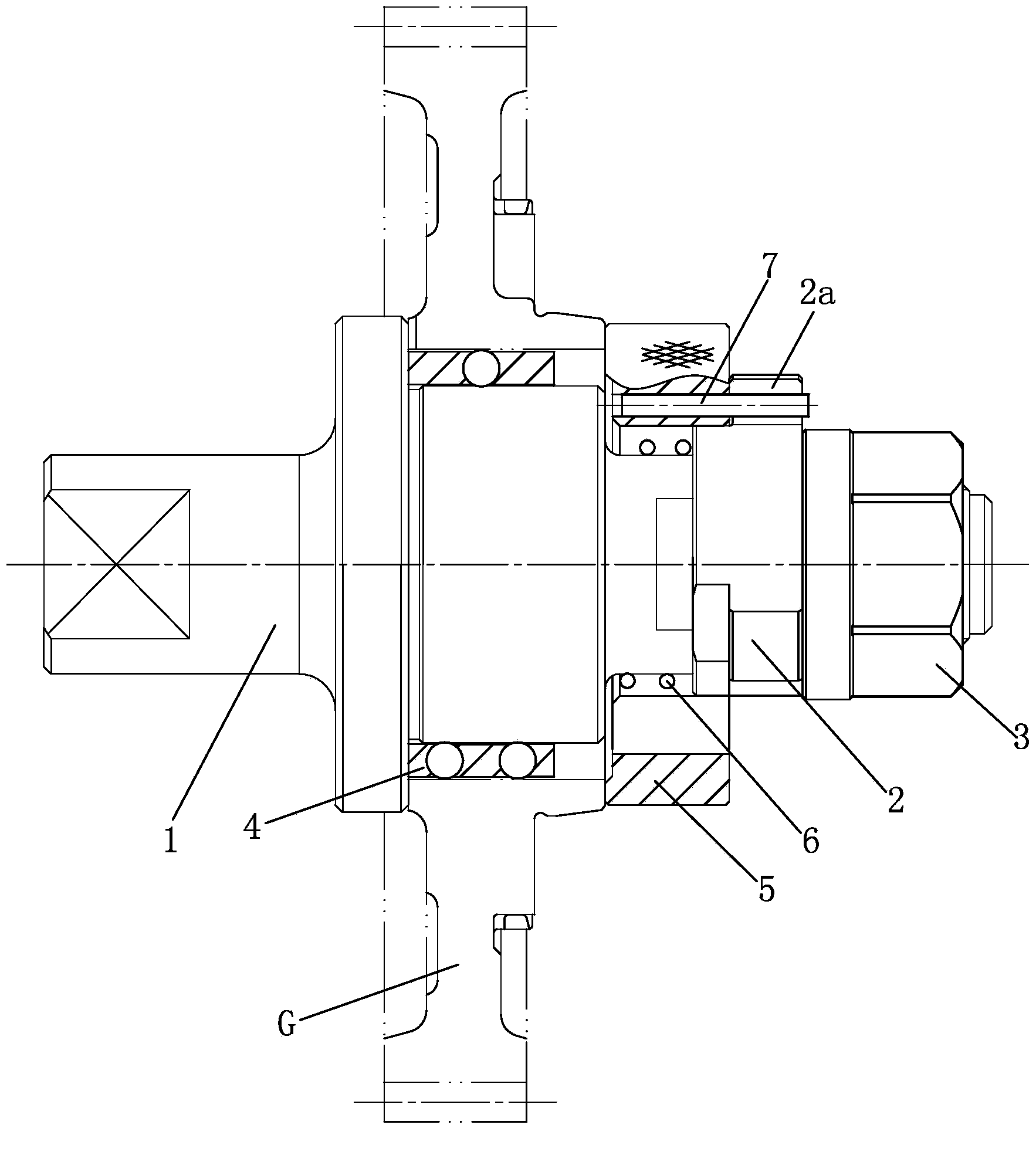

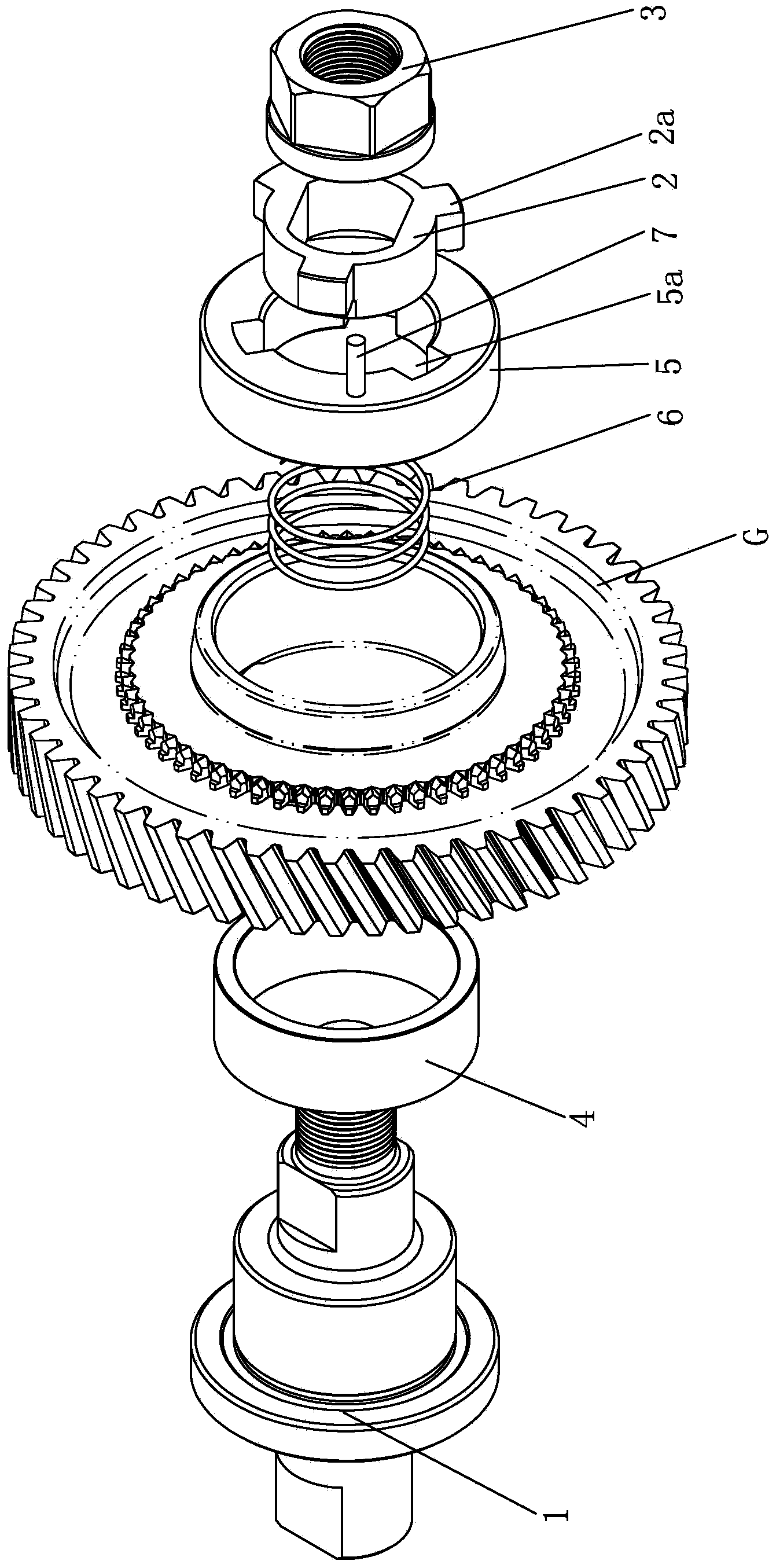

[0021] Such as figure 1 , 2 As shown, a quick clamping fixture is mainly composed of a mandrel 1, a pressure plate 2, a nut 3, a copper-based steel ball cage 4, a cover plate 5, a compression spring 6 and a positioning pin 7. Wherein, the mandrel 1 is a five-stage stepped shaft structure, which are the first, second, third, fourth and fifth shaft sections from left to right, wherein the diameter of the first shaft section is smaller than the diameter of the second shaft section, and the diameter of the second shaft section is smaller than that of the second shaft section. The diameters of the second, third, fourth and fifth shaft sections decrease sequentially, and the first shaft section and the fourth shaft section are flat sections, while the fifth shaft section is an external thread section.

[0022] A copper-based steel ball cage 4 is set on the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com