Carbon crystal electric warming mat

A carbon crystal and electric heating technology, which is applied in the direction of electrical components, electric heating systems, electric heating devices, etc., can solve the problems of low energy consumption, inability to use safe voltage, and inability to achieve high and low temperature gear control, etc., to achieve low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

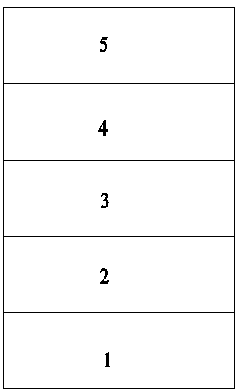

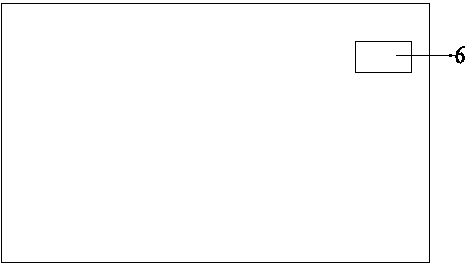

[0030] Embodiment 1: A carbon crystal electric heating pad, the carbon crystal electric heating pad includes a five-layer structure, and the five-layer structure is an anti-slip layer 1, a first adhesive layer 2, and a PTC constant temperature double-sided structure from bottom to top. Heating layer 3, second adhesive layer 4, and decorative layer 5; the first adhesive layer 2 bonds the non-slip layer 1 to one side of the PTC constant temperature double-sided heating layer 3; the second adhesive layer 4 bonds the PTC constant temperature double-sided heating The other side of the layer 3 is bonded to the decorative layer 5; the PTC constant temperature double-sided heating layer 3 is provided with electrodes, and the carbon crystal electric heating pad is provided with a control switch 6, and the control switch 6 is connected to the electrodes of the PTC constant temperature double-sided layer 3.

[0031] In this embodiment, the PTC constant temperature double-sided heating lay...

Embodiment 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in this embodiment, the side of the first PTC heating sheet printed with the first PTC heating carbon paste is covered with a protective film. The film is combined with the first layer of PTC heating sheet; the side of the second layer of PTC heating sheet printed with the second PTC heating carbon paste is covered with a protective film, and the protective film and the second layer of PTC The heating sheet is combined into one body. The protective film is made of polyester material.

Embodiment 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 is: in this embodiment, the spacing between the plurality of electrode lines on the first layer of PTC heating sheet is 100mm; the plurality of electrode lines on the second layer of PTC heating sheet The spacing between the root electrode wires is 100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com