Flywheel with variable rotational inertia

A technology of moment of inertia and flywheel, which is applied in the field of flywheel, can solve the problems of limited engine rated speed range, poor comprehensive performance of the engine, high consumption, etc., and achieve the goal of expanding the rated speed range, improving comprehensive performance and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

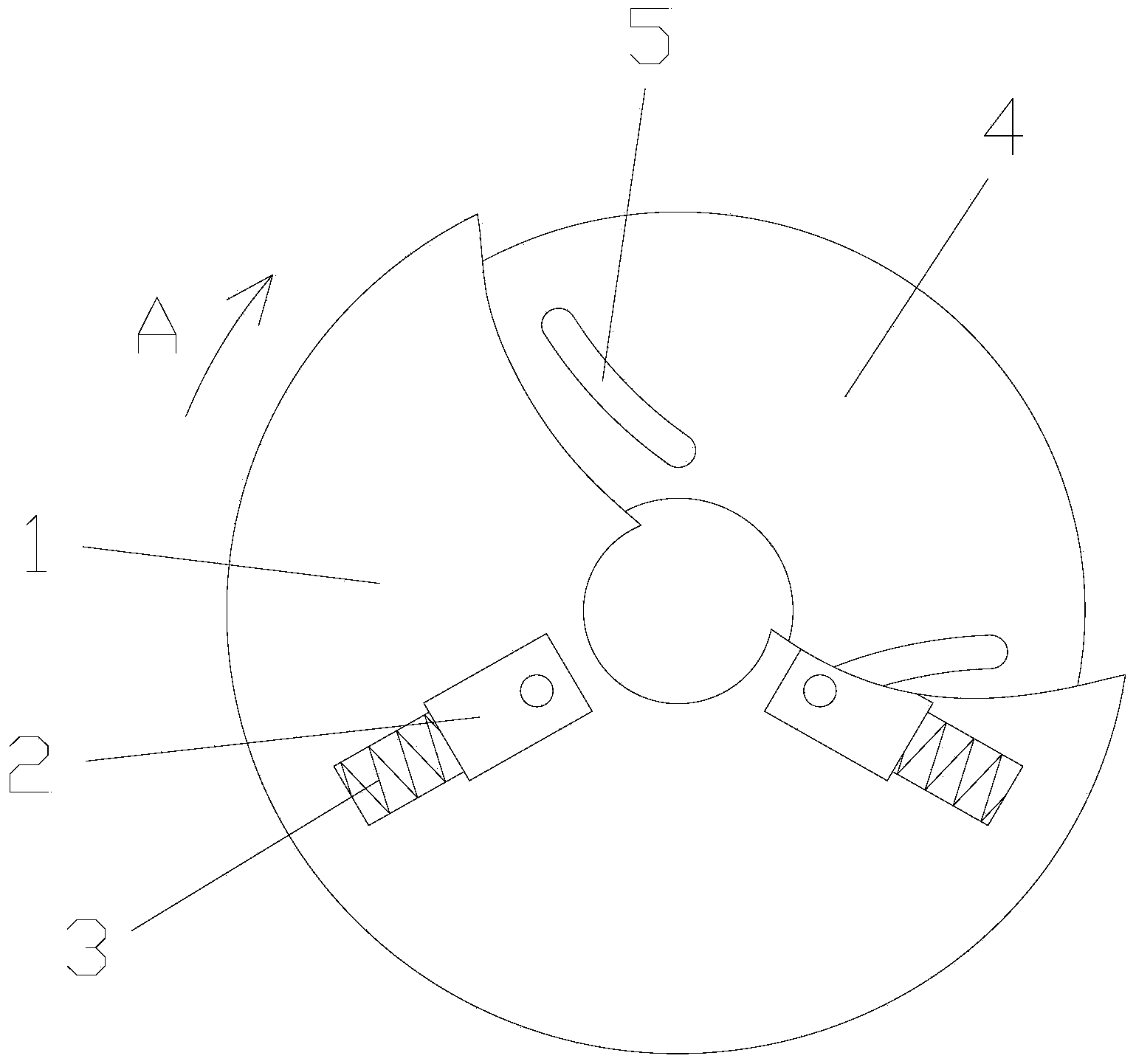

[0014] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the flywheel with variable moment of inertia of the present invention includes a flywheel body 1, a slider 2 and an elastic member 3; the sliders 2 are at least two and rotate around the flywheel body 1 Evenly arranged, each slider 2 is radially slidably connected to the flywheel body 1; the elastic member 3 is connected between the slider 2 and the flywheel body 1 to provide elastic centripetal force for the slider 2, figure 1 The direction of the arrow at A in the middle is the turning direction of the flywheel body 1. Each slider 2 is arranged symmetrically around the rotation axis of the flywheel body 1. When the speed of the flywheel body 1 increases, the sliders 2 can overcome the elastic centripetal force and move radially outward along the flywheel body 1. Sliding, and then make the moment of inertia of the whole flywheel larger, otherwise make the moment of ine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com