Gasoline engine pressure lubrication system and its gasoline engine

A technology of lubrication system and gasoline engine, applied in pressure lubricant, pressure lubrication of lubricating pump, lubrication of engine, etc., can solve problems such as optimization of unfavorable lubrication system layout, increase of production and assembly cost, and increase of assembly process complexity. , to optimize the layout of the lubrication system, reduce production and assembly costs, and achieve better coordination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

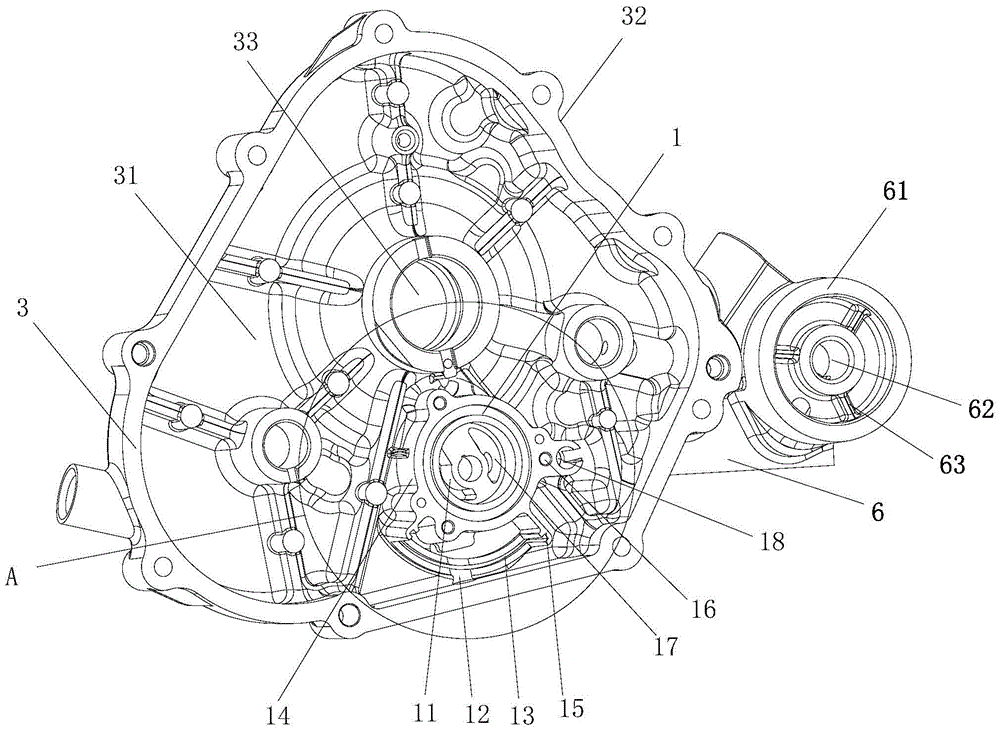

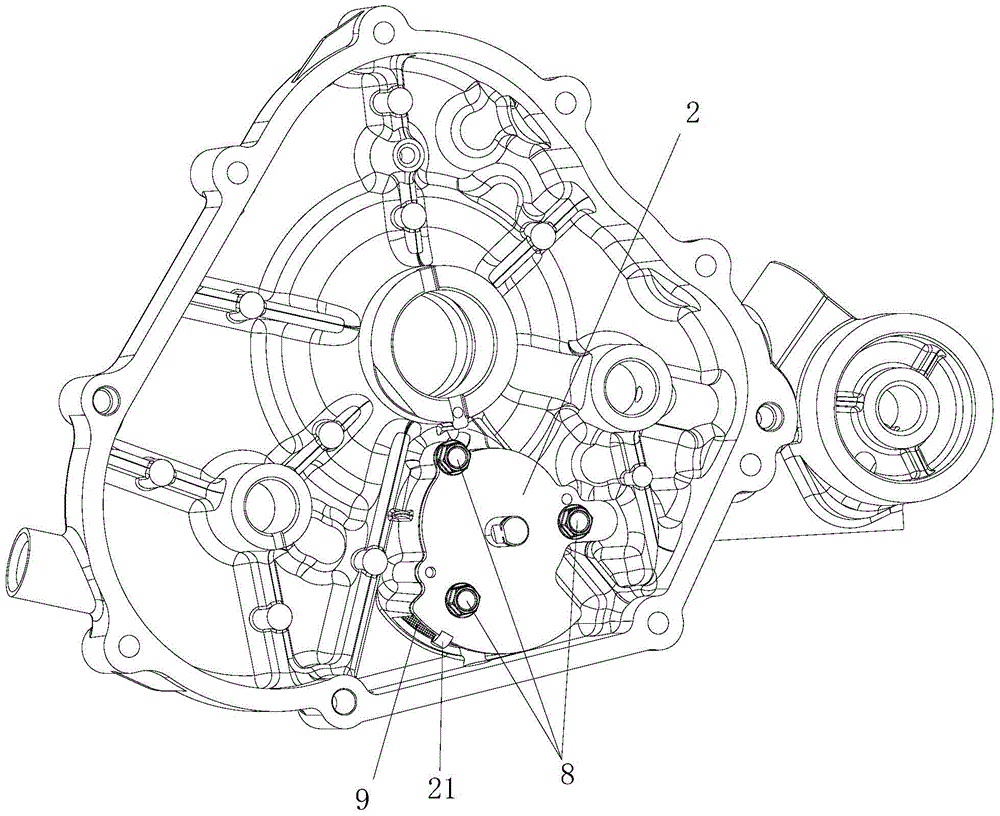

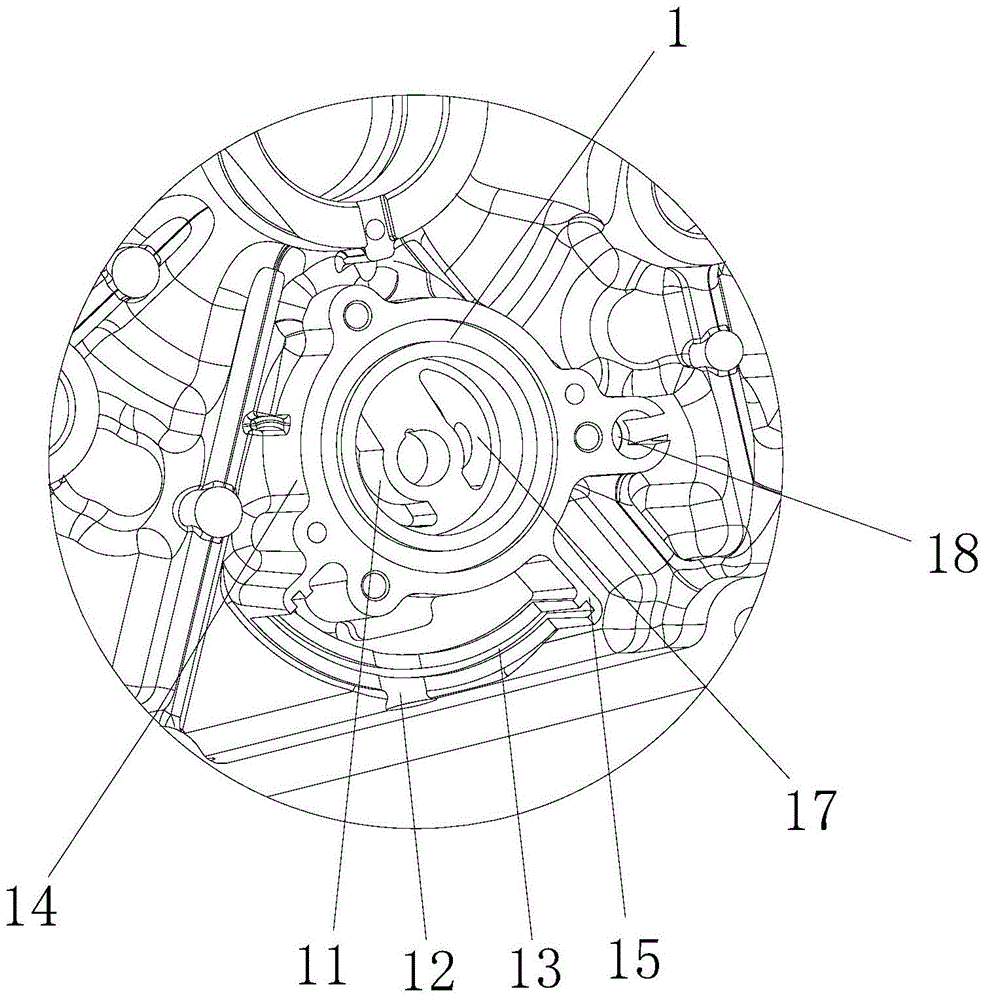

[0022] figure 1 It is a schematic diagram of the structure of the present invention before the oil pump cover plate is installed, figure 2 It is a schematic diagram of the structure of the present invention after the oil pump cover is installed, image 3 for figure 1 Enlarged view at center A, Figure 4 It is a cross-sectional view of the present invention after assembling the oil pump, as shown in the figure: the gasoline engine pressure lubrication system of the present invention includes an oil pump housing 1 and an oil pump cover plate 2 that is matched with the oil pump housing. The oil pump housing 1 includes a rotor mounting seat 14, an oil filter installation groove 13, and a cover installation column 16. The oil pump housing 1 and the crankcase cover 3 are integrated, and the filter installation groove 13 is provided in the oil pump Between the oil inlet cavity 11 and the oil inlet 12 of the housing 1, the cover mounting post 16 is arranged on the outer wall of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com