T-shaped foundation bolt hole plugging method

An anchor bolt and hole technology, which is applied in construction, infrastructure engineering and other directions, can solve the problems of large input of manpower and material resources, long construction time, and large environmental pollution, and achieves small input of manpower and material resources, little environmental pollution, and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

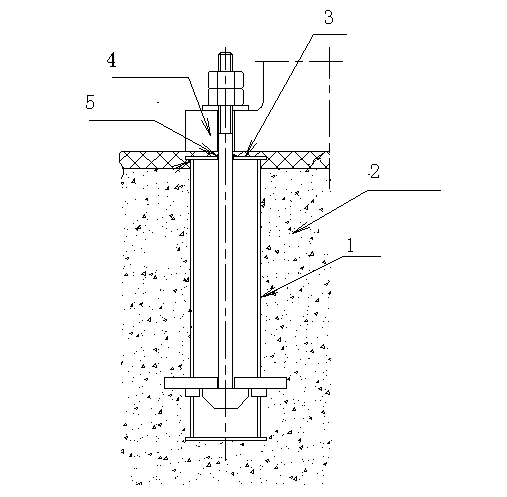

[0013] See figure 1 , the present invention a kind of T-shaped anchor bolt hole plugging method, it comprises the following steps:

[0014] Step 1, burying the anchor bolt sleeve 1, the upper surface of the sleeve is higher than the surface of the equipment foundation 2;

[0015] Step 2, when retesting the foundation, the upper surface of the anchor bolt sleeve needs to be cut horizontally and polished;

[0016] Step 3, making the sealing steel plate 3: Make a square steel plate with a thin steel plate, the side length of the sealing steel plate is 100mm larger than the diameter of the anchor bolt hole, and open a round hole in the center, the diameter of the round hole should be larger than the anchor bolt hole The diameter of the hole is 1mm larger;

[0017] Step 4, before the equipment 4 is installed in place, put the prepared sealing steel plate on the anchor bolt, and use silica gel 5 to seal the gap between the anchor bolt hole sealing plate and the anchor bolt;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com