Impeller and impeller washing machine

A pulsator washing machine and pulsator technology, applied in the field of washing machines, can solve problems such as poor cleaning effect, poor clothing turnover, and weak washing power of pulsator washing machines, and achieve the effects of preventing entanglement of clothes, improving the washing ratio, and ideal washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] The pulsator in this embodiment includes a base plate, on the upper surface of the base plate, a plurality of convex ribs are formed, and the convex ribs are used to stir the water in the tub to form a water flow to impact the clothes and form a certain washing force on the clothes. Water-repellent ribs are formed on the lower surface of the base plate and the concave part corresponding to the convex rib, and a through hole is opened on the concave (that is, the convex rib), and the water on the lower surface of the pulsator can enter the washing tub through the through hole on the convex rib Inside. Wherein, the upper surface of the base plate is the surface inside the washing bucket after the pulsator is assembled with the washing bucket, and the lower surface of the base plate is the reverse side of the upper surface of the base plate.

[0028] During the forward and reverse rotation of the pulsator, a large amount of water is gathered at the water-repelling ribs, so...

specific Embodiment 2

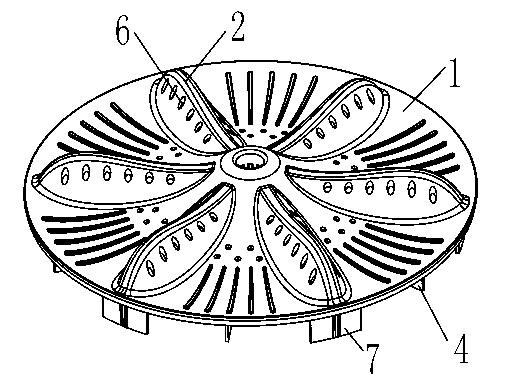

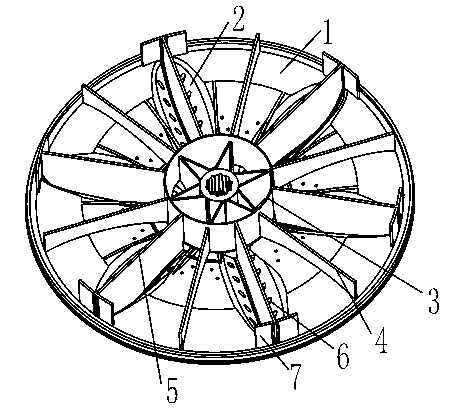

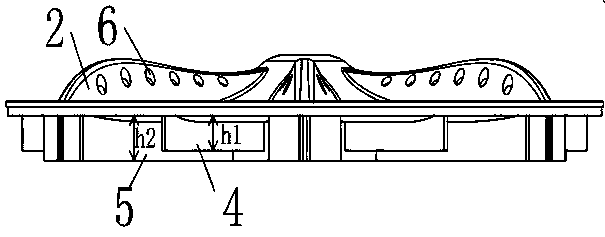

[0029] Such as Figure 1-3 As shown, the pulsator proposed in this embodiment is integrally injection-molded, including a disc-shaped substrate 1. The upper surface of the substrate 1 described in this embodiment is the surface located in the washing tub after the pulsator is assembled with the washing tub. The lower surface of the substrate 1 is opposite to the upper surface of the substrate.

[0030] Protruding ribs 2 protruding from the surface of the substrate 1 are formed on the upper surface of the substrate 1 , and the ribs 2 are distributed in a radial shape with the center of the substrate 1 as a base point. On the lower surface of the base plate 1 corresponding to the convex rib 2 is a depression, the depression includes two inclined sides, and the inclined sides intersect. Each depression is formed with a water-draining rib 5, which is a vertical rib formed on the lower surface of the substrate 1. The water-draining rib 5 extends outward based on the component 3 un...

specific Embodiment 3

[0040] Such as Figure 7-8 As shown, the difference between this embodiment and specific embodiment 2 is that this embodiment only has a through hole 6 evenly opened on one inclined side of the depression, while no through hole is opened on the other inclined side, and the water-repellent rib 5 is formed On the sloped sides of the depression. Then only when the pulsator rotates clockwise or counterclockwise, a spray-like water flow is formed on the inclined side surface provided with the through hole 6, which has the effect of enhancing the washing power and improving the degree of cleanliness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com