A preparation method of titanium dioxide film coating on the surface of titanium alloy microporous bone

A technology of titanium dioxide and alloy micropores, which is applied in the field of medical bioactive composite materials, can solve the problems of high manufacturing cost, intensified corrosion of alloy surface, failure to achieve ideal clinical application effect, etc., and achieve low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] 1. First adjust the molar ratio TiPT (titanium isopropoxide): C 3 h 8 O (anhydrous isopropanol): HCL (hydrochloric acid): H 2 O (water)=1.0:9.1:0.15:1.1 Stir with a magnetic stirrer for 20 minutes, and keep the temperature at 0 0 C aged for 12 hours.

[0019] 2. Then put Ti 6 A1 4 The V alloy microporous bone was immersed in the above titanium solution for 24 hours, and its temperature was kept at 15 0 c.

[0020] 3. Then Ti 6 A1 4 V alloy microporous bone samples with a size of 10mm*30mm*1mm were soaked in 40ml of 0.5mol / l nitric acid solution for 10 days, and the temperature was kept at 50 0 c.

[0021] 4. Ti 6 A1 4 The V alloy microporous bone sample was slowly taken out of the nitric acid aqueous solution at a speed of about 3 cm / min and cooled at room temperature.

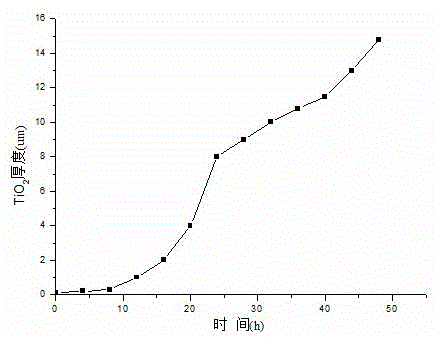

[0022] The thickness of the titanium dioxide film coating on the surface of Ti6A14V alloy microporous bone is 8.48 μm as measured by scanning electron microscope JEM-1400 / 1011. Ti was obtai...

example 2

[0025] 1. First adjust the molar ratio TiPT (titanium isopropoxide): C 3 h 8 O (anhydrous isopropanol): HCL (hydrochloric acid): H 2 O (water)=1.0:9.1:0.15:1.1 stirred for 20 minutes with a magnetic stirrer, and its temperature was kept at 10 0 C aging for 15 hours.

[0026] 2. Then put Ti 6 A1 4 The V alloy microporous bone was immersed in the above titanium solution for 36 hours, and its temperature was kept at 20 0 c.

[0027] 3. Then Ti 6 A1 4 The V alloy microporous bone sample size is 10mm*30mm*1mm, soaked in 40ml of 0.5mol / l nitric acid solution for 12 days, and the temperature is kept at 60 0 c.

[0028] 4. Ti 6 A1 4 The V alloy microporous bone sample was slowly taken out of the nitric acid aqueous solution at a speed of about 3 cm / min and cooled at room temperature.

[0029] The product was determined by scanning electron microscope JEM-1400 / 1011, Ti 6 A1 4 The thickness of titanium dioxide film coating on the surface of V alloy microporous bone is 10.8...

example 3

[0031] 1. First adjust the molar ratio TiPT (titanium isopropoxide): C 3 h 8 O (anhydrous isopropanol): HCL (hydrochloric acid): H 2 O (water)=1.0:9.1:0.15:1.1 Stir with a magnetic stirrer for 20 minutes, and keep the temperature at 15 0 C aged for 18 hours.

[0032] 2. Then put Ti 6 A1 4 The V alloy microporous bone was immersed in the above titanium solution for 48 hours, and its temperature was kept at 25 0 c.

[0033] 3. Then Ti 6 A1 4 The size of V alloy microporous bone sample is 10mm*30mm*1mm, soaked in 40ml of 0.5mol / l nitric acid solution for 15 days, and the temperature is kept at 70 0 c.

[0034] 4. Ti 6 A1 4 The V alloy microporous bone sample was slowly taken out of the nitric acid aqueous solution at a speed of about 3 cm / min and cooled at room temperature.

[0035] The product was determined by scanning electron microscope JEM-1400 / 1011, Ti 6 A1 4 The thickness of titanium dioxide film coating on the surface of V alloy microporous bone is 14.98 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com