ZG25MnSY3 casting material and preparation method thereof

A casting and slag technology, applied in the field of ZG25MnSY3 casting materials, can solve the problems of easy deformation, wear resistance, insufficient fatigue resistance, fracture, etc., and achieve the effect of improving strength and toughness, prolonging service life and reducing replacement frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

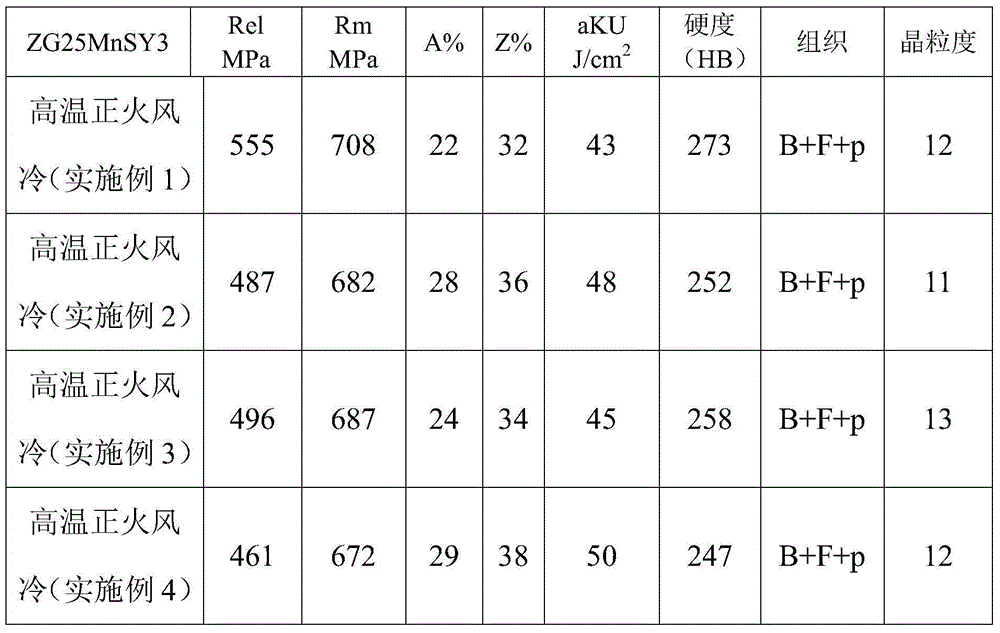

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in combination with specific embodiments.

[0032] ZG25MnSY3 casting material of the present invention is made up of following components according to mass %:

[0033] C is 0.25%-0.3%, Si is 0.3%-0.45%, Mn is 1%-1.2%, P is ≤0.02%, S is ≤0.015%, Cr is 0.3%-0.6%, Ni is 0.4%-0.6 %, Mo is 0.3%-0.45%, V is 0.09%-0.15%, Nb is ≤0.05%, Cu is ≤0.3%, Al is 0.03%-0.06%, and the rest is Fe, totaling 100%.

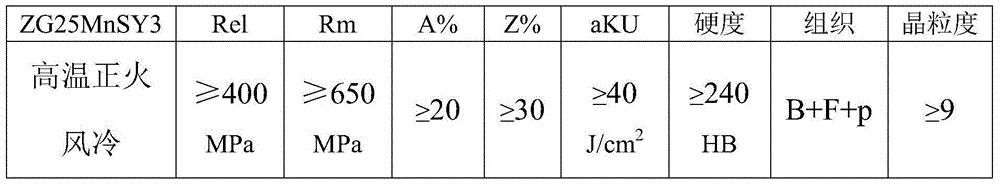

[0034] With reference to Table 1, it is the required performance index of the structure design of the ZG25MnSY3 casting material of the present invention.

[0035] Table 1, ZG25MnSY3 casting material structure design requirement performance index of the present invention

[0036]

[0037] Other technical indicators of ZG25MnSY3 casting material of the present invention also include:

[0038] 1) O≤50ppm, H≤10ppm, N≤150ppm;

[0039] 2) The annealed structure is pearlite plus ferrite, with a grain size above grade 8;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com