Comprehensive treatment device of industrial waste salt based on high temperature heat pipe

A high-temperature heat pipe and comprehensive treatment technology, which is applied in the petroleum industry, special carbonization, coking ovens, etc., can solve the problems of waste of resources, environment, pollution, etc., and achieve the effects of energy saving, high thermal efficiency, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

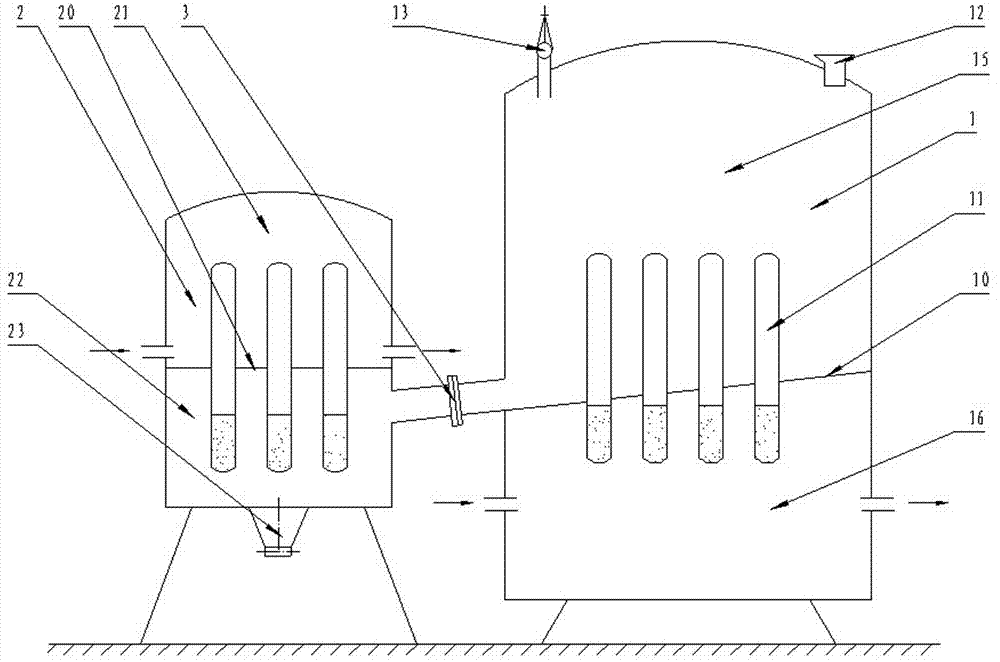

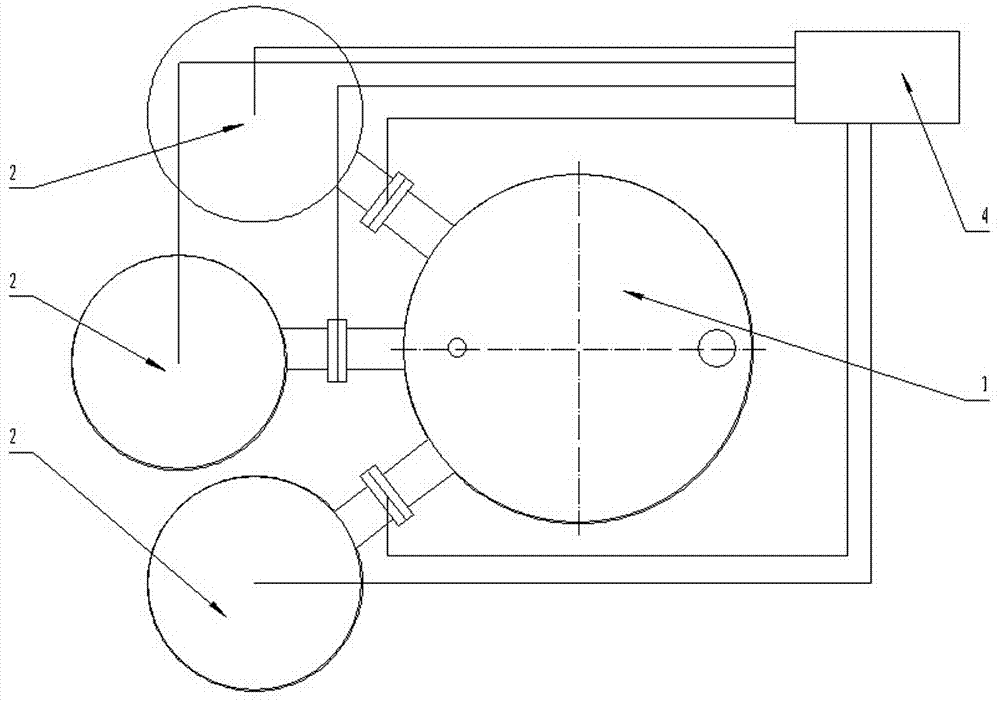

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Industrial waste salt treatment generally includes the following steps:

[0014] The first step is to pre-treat the collected industrial waste salt materials to remove the water in them. The material is then heated to 400 degrees Celsius.

[0015] In the second step, high-temperature pyrolysis is performed on the material treated in the first step, the purpose of which is to remove the organic components in the industrial waste salt.

[0016] In this step, a rotary kiln incinerator can be used for treatment, and the temperature in the kiln should reach 500-800 degrees Celsius, which can completely remove the organic components in the industrial waste salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com