Photochromic film, photochromic glass and preparation method

A photochromic glass and photochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, glass/slag layered products, etc., to achieve the effects of low cost, improved color-changing performance, and good color-changing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

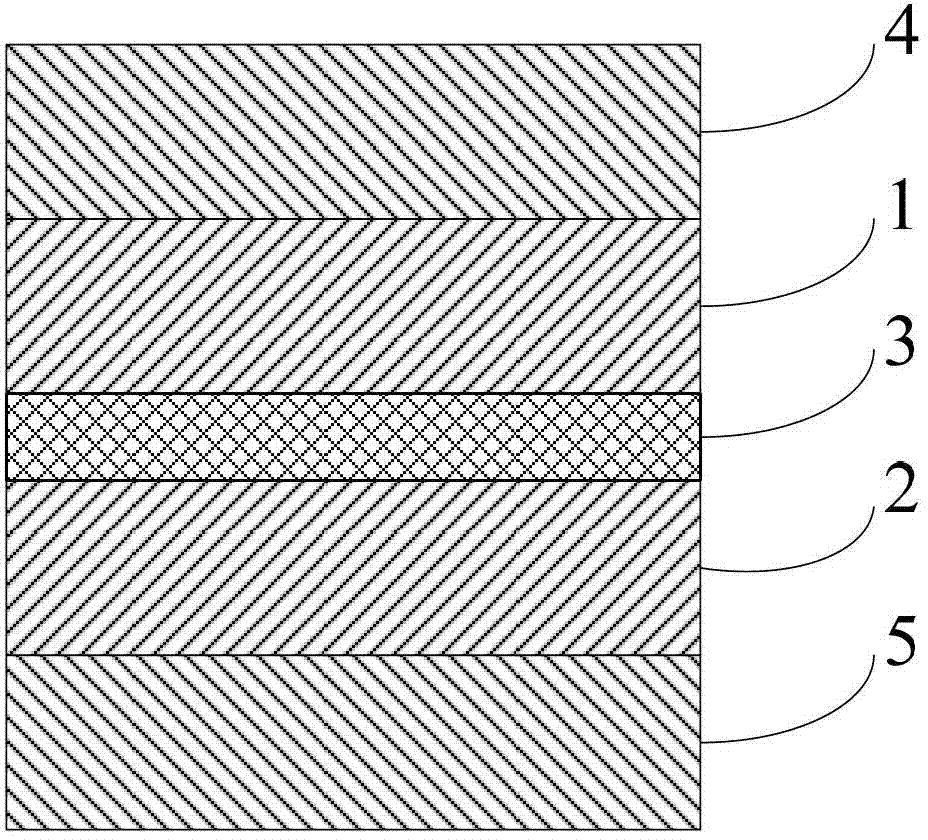

Image

Examples

preparation example Construction

[0027] Specifically, the photochromic film preparation method includes the following steps:

[0028] Provide polyvinyl butyral, plasticizer, coupling agent and the above-mentioned photochromic powder, the photochromic powder, polyvinyl butyral, plasticizer and coupling agent according to the following weight percentage mix to get a mixture;

[0029] Add the mixture to a mixer and stir for 10-20 minutes, heat it to 140-160°C to melt and extrude it into a film of 0.38-3.04mm, and then cool, remove water, blow dry, etc., to obtain photoinduced Color-changing film; the weight percentage of each component is as follows:

[0030]

[0031] Specifically, the polyvinyl butyral, plasticizer, coupling agent and photochromic powder are the same as those described above, and will not be repeated here.

[0032] The photochromic film of the embodiment of the present invention has a better color changing effect by selecting the above photochromic powder.

[0033] The embodiment of the p...

Embodiment 1

[0049] The preparation method of the photochromic glass of this embodiment comprises the following steps:

[0050] The first step is to prepare PVB photochromic film:

[0051] Get 85% by weight of polyvinyl butyral, 13.5% by weight of triethylene glycol di-n-heptanoate, 1.15% by weight of vinyltriethoxysilane and 0.35% by weight of helicopyran organic photochromic powder, uniform After mixing, add it to a mixer and stir for 10 minutes, heat to 150°C to melt and extrude to make a film, and after cooling, dewatering, drying, etc., a photochromic film is obtained;

[0052] The second step is to prepare photochromic laminated glass:

[0053] Clamp a piece of photochromic film prepared in Step 2 of the same area between two pieces of glass with clean surfaces, put them together in a silica gel bag, exhaust them under 2.5KPa vacuum for 20 minutes, and transfer them to a drying oven at 85°C Insulate for 30 minutes; then heat-press in an autoclave at 1.3MPa and 135°C for 25 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com