A preparation method of polysaccharide iron complex and its quality detection method

A complex and polysaccharide iron technology, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve problems such as unsatisfactory production yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

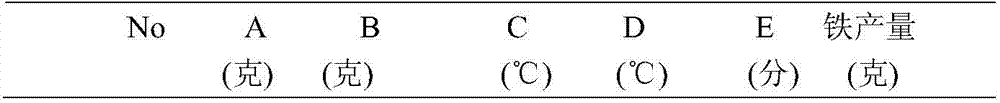

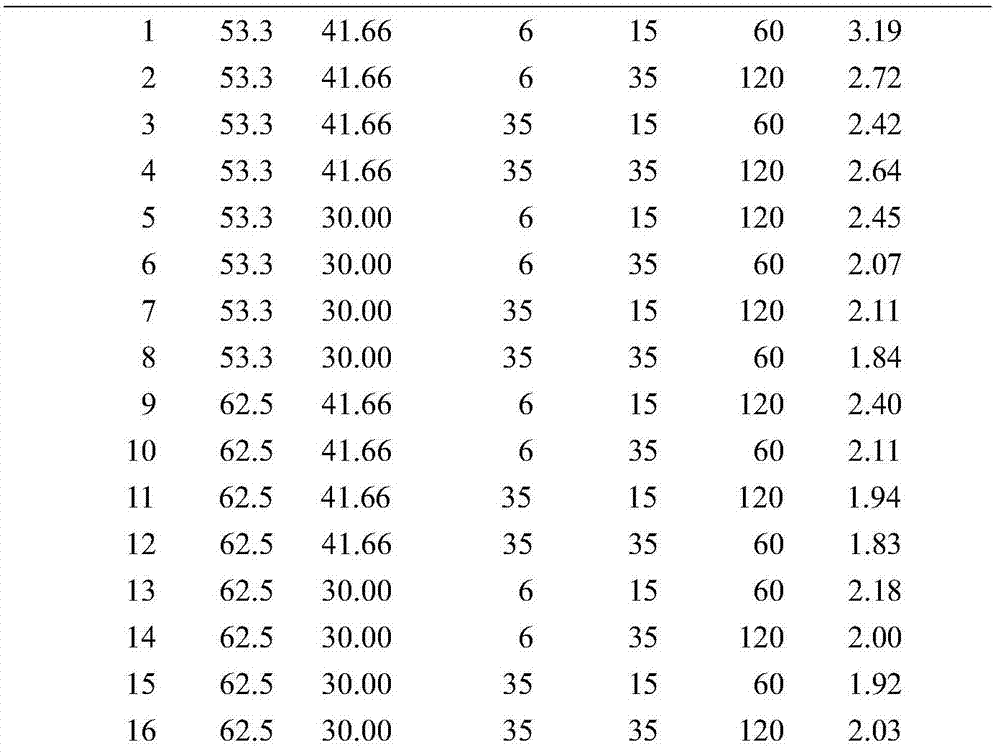

[0064] Experimental Example 1 Optimum Reaction Condition Determination Experiment

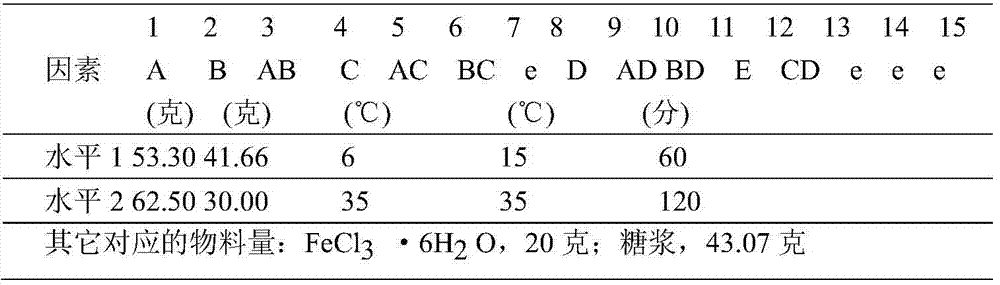

[0065] The experiment was designed by orthogonal design to determine the optimal reaction conditions. Five factors were selected: A. The amount of sodium carbonate, expressed in grams of 0.2 (W / W) sodium carbonate aqueous solution; B. The concentration of ferric chloride aqueous solution, expressed in terms of the amount of water used to dissolve ferric chloride Indicates, in grams; C. The temperature in the reactor when sodium carbonate is added, ℃; D. The temperature in the reactor when sodium hydroxide is added, ℃; E. The reaction time required for adding sodium carbonate, minutes, choose L 16 (2 15 ) orthogonal table, the table header is as follows:

[0066] Table 1 Orthogonal design header (L 16 (2 15 ))

[0067]

[0068] The selected assessment index is the iron output, which is the product of the polysaccharide iron amount obtained by the reaction and its iron content, i.e. W pro...

experiment example 2

[0079] Experimental example 2 detailed preparation method and its basis experiment

[0080] Using the preparation method described in Example 1, Table 6 provides the proportioning and product yield of each material, from which the material balance of the process can be carried out. As seen from Table 6, it is 40% relative to the product mass yield of ferric chloride. The reaction steps are few, the reaction conditions are relatively mild, and it is easy to master. As long as the ingredients and operating conditions are followed, the yield can be achieved, and most of the impurities can be easily removed by precipitation and centrifugation. In the preparation method of the present invention, the polysaccharide-iron complex is washed twice to wash away the remaining uncomplexed ferric ions and polysaccharides, and remove the contained chloride ions and sodium ions at the same time, and the impurity content is already small .

[0081] Table 6 Process conditions, material ratio ...

experiment example 3

[0085] Experimental Example 3 The control of the first alkali dropwise addition of the polysaccharide-iron complex of the present invention

[0086] In production research engineering, the yield of polysaccharide-iron complex is sometimes high, sometimes low, and sometimes even the final product cannot be obtained. After a lot of experimental research, it was unexpectedly found that the control of the first addition of lye is a key link. If the addition is too fast or excessive, the polysaccharide-iron complex cannot be formed later. After a large number of experiments, it was found that 700-1100 parts by weight of 20% sodium carbonate aqueous solution was added to the reaction tank within 60-90 minutes (preferably 85, 65, and 70 minutes), and the reaction temperature was controlled at 0-10°C (preferably 3-9°C, 6°C, 4°C, 8°C), after the feeding is completed, continue to stir for 15-30 minutes, after the stirring is completed, the reaction solution is raised to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com