Medical Laser Printing Film

A laser printing and film technology, applied in the field of medical supplies, can solve the problems of serious pollution, limited use, time-consuming and labor-intensive, etc., and achieve the effects of high bonding strength, good ozone resistance, and good color reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

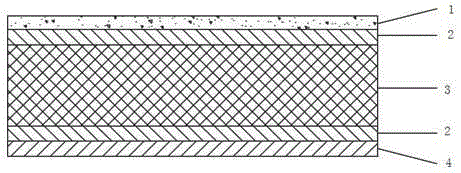

[0027] Such as figure 1 As shown, the medical laser printing film includes a substrate 3 and a coating on the substrate 3, the substrate 3 includes a transparent or translucent PET sheet, and the coating includes an exclusive laser printing ink-absorbing layer 1, an antistatic Layer 4 and intermediate adhesive layer 2, the intermediate adhesive layer 2 is coated on one side of the substrate 3, the other side of the intermediate adhesive layer 2 is coated with an exclusive laser printing ink-absorbing layer 1, and the other side of the substrate 3 is also coated with an intermediate adhesive layer. A junction layer 2, the other side of the intermediate bonding layer 2 is coated with an antistatic layer 4;

[0028] The exclusive laser printing ink-absorbing layer 1 includes the following components: EVA resin 95kg, whitening agent 0.5kg, dispersant 1.5kg, antistatic agent 3kg.

[0029] The exclusive laser printing ink-absorbing layer 1 is directly coated on the intermediate adh...

Embodiment 2

[0032] Such as figure 1 As shown, the medical laser printing film includes a substrate 3 and a coating on the substrate 3, the substrate 3 includes a transparent or translucent PET sheet, and the coating includes an exclusive laser printing ink-absorbing layer 1, an antistatic Layer 4 and intermediate adhesive layer 2, the intermediate adhesive layer 2 is coated on one side of the substrate 3, the other side of the intermediate adhesive layer 2 is coated with an exclusive laser printing ink-absorbing layer 1, and the other side of the substrate 3 is also coated with an intermediate adhesive layer. A junction layer 2, the other side of the intermediate bonding layer 2 is coated with an antistatic layer 4;

[0033] The ink-absorbing layer 1 for exclusive laser printing includes the following components: 93kg of EVA resin, 0.3kg of whitening agent, 1.7kg of dispersant, and 5kg of antistatic agent.

[0034] The exclusive laser printing ink-absorbing layer 1 is directly coated on ...

Embodiment 3

[0037] Such as figure 1 As shown, the medical laser printing film includes a substrate 3 and a coating on the substrate 3, the substrate 3 includes a transparent or translucent PET sheet, and the coating includes an exclusive laser printing ink-absorbing layer 1, an antistatic Layer 4 and intermediate adhesive layer 2, the intermediate adhesive layer 2 is coated on one side of the substrate 3, the other side of the intermediate adhesive layer 2 is coated with an exclusive laser printing ink-absorbing layer 1, and the other side of the substrate 3 is also coated with an intermediate adhesive layer. A junction layer 2, the other side of the intermediate bonding layer 2 is coated with an antistatic layer 4;

[0038] The exclusive laser printing ink-absorbing layer 1 includes the following components: EVA resin 97kg, whitening agent 0.3kg, dispersant 1kg, antistatic agent 2.7kg.

[0039] The exclusive laser printing ink-absorbing layer 1 is directly coated on the intermediate adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com