Cold heat recovery apparatus using an lng fuel, and liquefied gas carrier including same

A technology for recycling equipment and liquefied gas tanks, which is applied to equipment discharged from non-pressure vessels, liquefaction, auxiliary equipment, etc., can solve the problems of increasing the manufacturing cost of liquefied gas carriers, consuming additional energy, and complicated ship operations, and achieving The effect of reducing operating and installation costs, simplifying operations, reducing costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the configuration and operation of preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In addition, the following embodiments can be modified in various forms, and the following embodiments are not intended to limit the scope of the present invention.

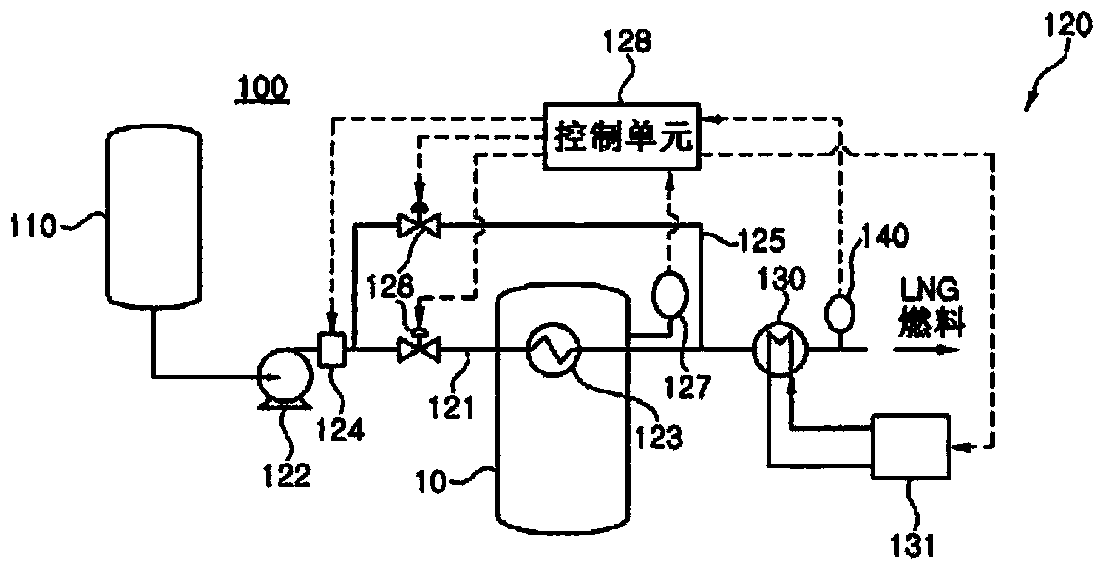

[0043] figure 1 is a configuration diagram illustrating a cold heat recovery facility using LNG fuel according to a first embodiment of the present invention.

[0044] Such as figure 1 As explained in , the cold heat recovery device 100 using LNG fuel according to the first embodiment of the present invention may include: an LNG fuel tank 110 configured to store LNG as a fuel; and a pressure control unit 120 used as a cold heat A member configured to control the pressure of the liquefied gas tank 10 by using low temperature characteristics, ie, the coldness and heat of the LNG discharged from the LNG fuel tank 110 is used. Herein, the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com