Electromagnetic protection film with efficient shielding and electromagnetism absorption function

An electromagnetic absorption layer and protective film technology, applied in the fields of magnetic field/electric field shielding, electrical components, chemical instruments and methods, etc., can solve the problems of electromagnetic signal absorption, poor operation status of equipment, affecting the accurate operation of precision instruments, etc., and achieve high shielding. Effectiveness, good anti-interference and protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of coating liquid for conductive electromagnetic absorption layer 6:

[0042] Silver-coated copper powder with 10% silver content 20 g

[0043] Phosphate carbonyl iron powder LDT-20 (Shaanxi Xinghua Chemical Co., Ltd.) 20 grams

[0044] Epoxy general resin E-20 60g

[0045] Add the above-mentioned substances into the container and stir at high speed to obtain the coating liquid for use.

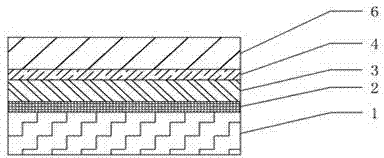

[0046] 2. Preparation of electromagnetic protective film

[0047] Coat the fluorine-modified amino resin release layer 2 on the 50um PET carrier film 1. After curing, coat the coating liquid composed of epoxy-modified polyurethane resin and carbon black filler on the surface of the release layer to form a thickness of 5um barrier edge layer 3; on the surface of the barrier edge layer, a silver-plated layer 4 with a thickness of 0.1um is vacuum evaporated, and the conductive electromagnetic absorption layer coating solution configured above is coated on the surface of t...

Embodiment 2

[0049] 1. Preparation of coating liquid for conductive electromagnetic absorption layer 6:

[0051] Phosphate carbonyl iron powder LDT-20 (Shaanxi Xinghua Chemical Co., Ltd.) 20 grams

[0052] No. 800 polyester resin 50 g

[0053] Add the above-mentioned substances into the container and stir at high speed to obtain the coating liquid for use.

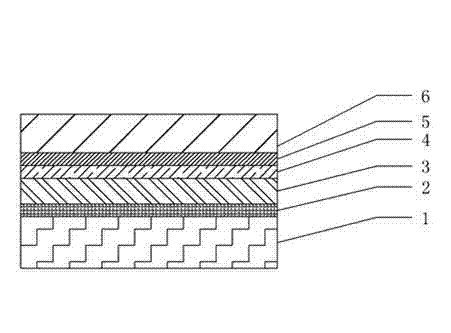

[0054] 2. Preparation of electromagnetic protective film

[0055] Coat the fluorine-modified amino resin release layer 2 on the 50um PET carrier film 1. After curing, coat the coating solution composed of epoxy-modified polyurethane resin and carbon black filler on the surface of the release layer to form a thickness 4um barrier edge layer 3; on the surface of the barrier edge layer, a silver-plated layer 4 with a thickness of 0.25um is vacuum-evaporated, and a copper-plated layer 5 with a thickness of 0.25um is vacuum-evaporated on the surface of the silver-plated layer, and coated on the surface of the co...

Embodiment 3

[0057] 1. Preparation of coating liquid for conductive electromagnetic absorption layer 6:

[0058] 30 grams of silver powder

[0059] EW Carbonyl Iron Powder (BASF Company) 20g

[0060] Epoxy general resin E-20 50g

[0061] Add the above-mentioned substances into the container and stir at high speed to obtain the coating liquid for use.

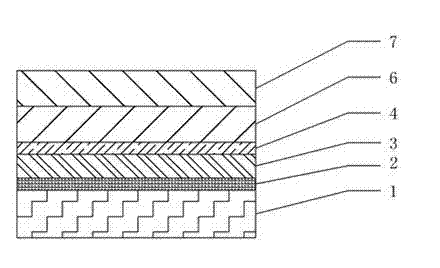

[0062] 2. Preparation of electromagnetic protective film

[0063] Coat the fluorine-modified amino resin release layer 2 on the 50um PET carrier film 1. After curing, coat the coating solution composed of epoxy-modified polyurethane resin and carbon black filler on the surface of the release layer to form a thickness The barrier layer 3 is 5.5um, the silver plating layer 4 with a thickness of 0.2um is vacuum evaporated on the surface of the barrier layer, and the conductive electromagnetic absorption layer coating solution configured above is coated on the surface of the copper plating layer to form a conductive layer with a thickness of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com