Method for predicting remaining service life of large rotating support on basis of small sample

A technology for slewing bearings and life prediction, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as undiscovered remaining life prediction methods for slewing bearings, achieve model accuracy reduction, speed up the test process, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

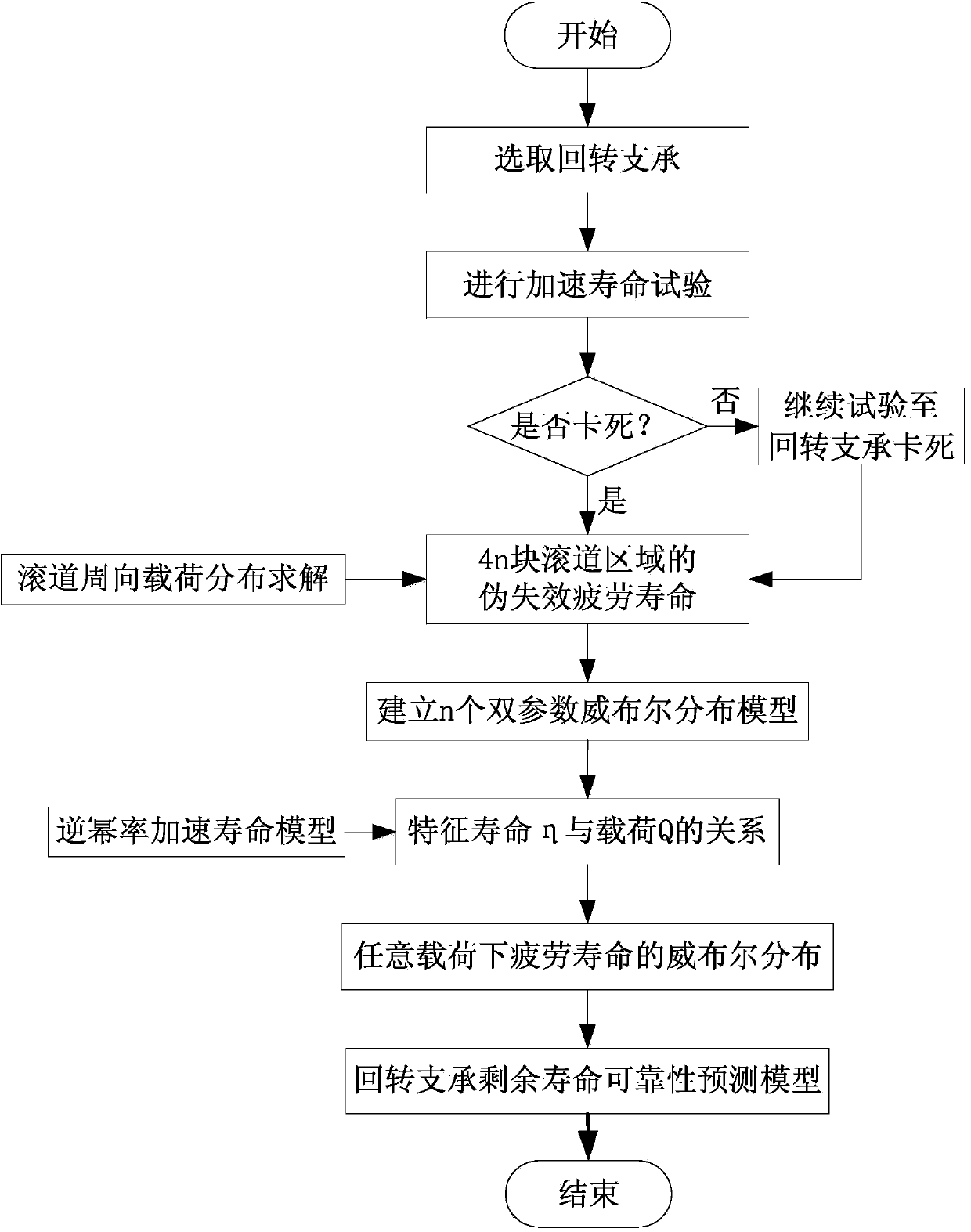

[0050] like figure 1 As shown, the implementation steps of this method are as follows:

[0051] 1) According to Weibull life distribution theory R=exp[-(t / η) β ], deduce the residual life prediction model of slewing bearing based on reliability R is the reliability, t is the number of turns of the slewing bearing, β and η are the slope of the Weibull distribution and the characteristic life of the corresponding bearing, which need to be determined through experiments.

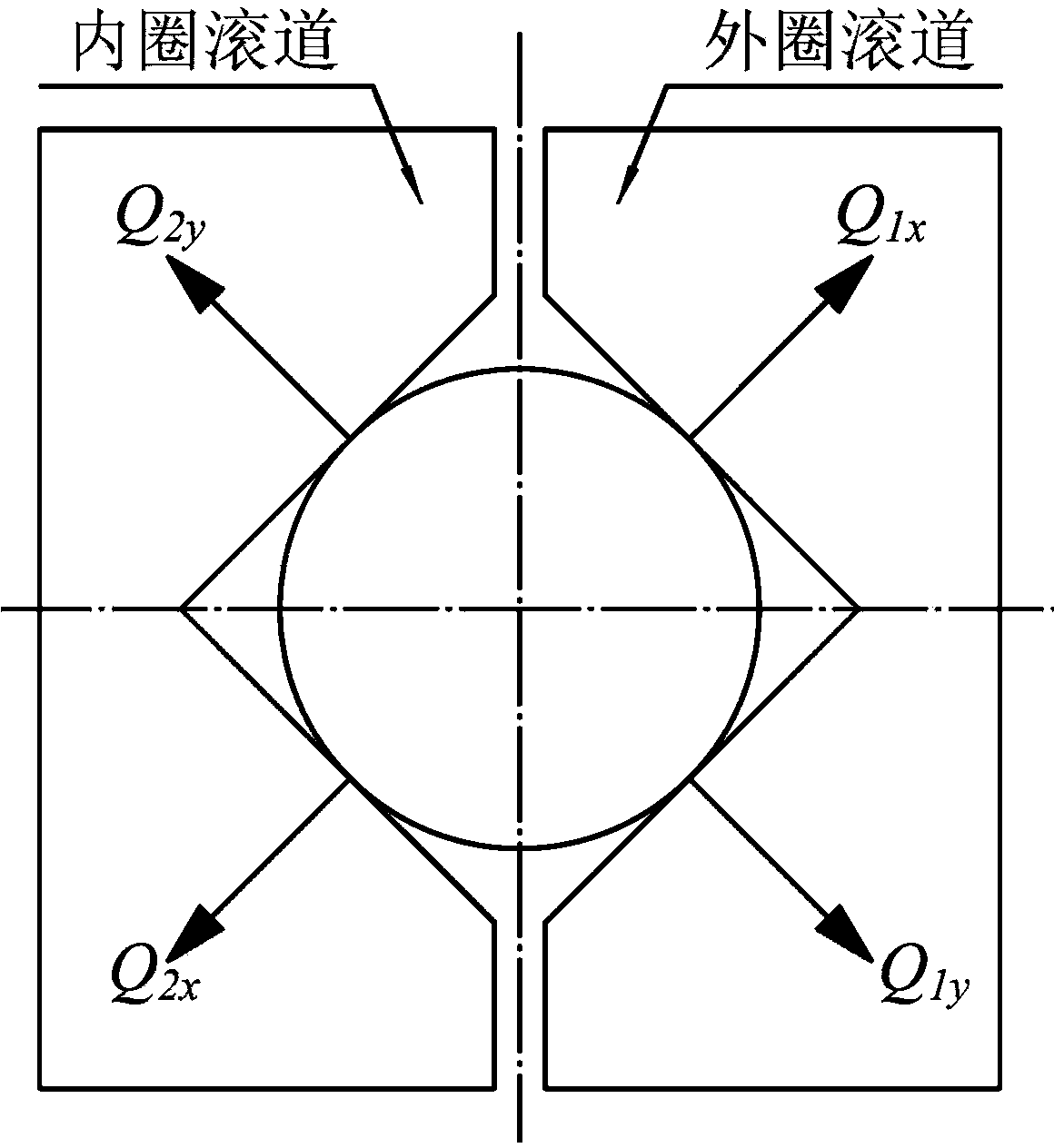

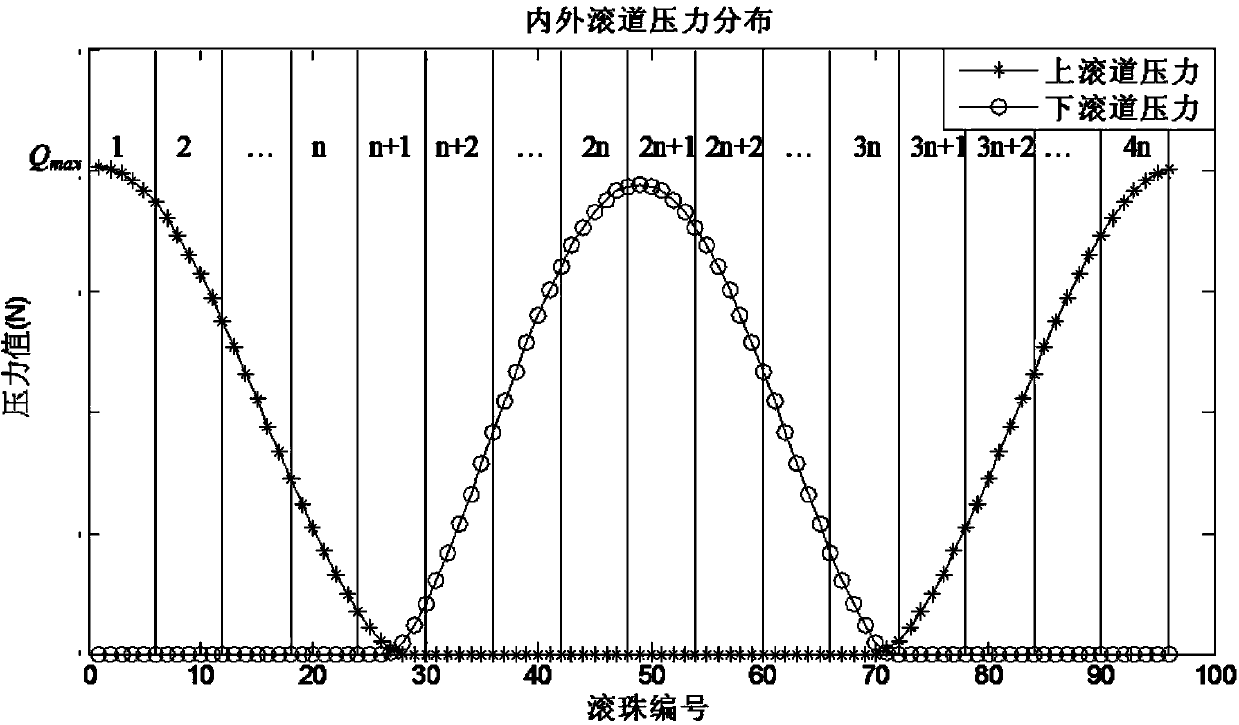

[0052] 2) According to Hertz contact theory and ISO281 method, the load distribution of the slewing bearing raceway is solved. Suppose the external loads on the slewing bearing are: axial force F a , radial force F r and overturning moment M, for a certain ball, such as figure 2 As shown, let the contact force between the four points of contact with the raceway be Q 1x ,Q 1y ,Q 2x and Q 2y , sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com