Modeling Method of Geometric Error Screw Theory for CNC Machine Tool

A technology of geometric error and modeling method, which is applied in the field of CNC machine tools, and can solve the problem that the six-dimensional pose error of the machine tool cannot be directly displayed and expressed in a unified manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

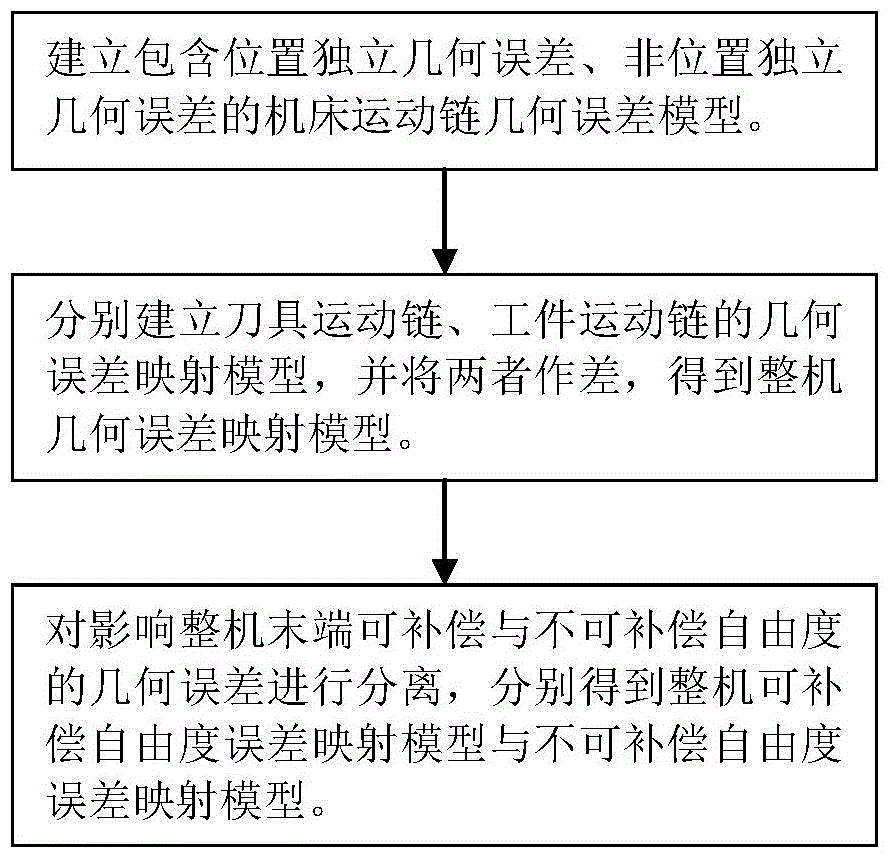

[0031] Step 1. Establish the geometric error model of the machine tool kinematic chain

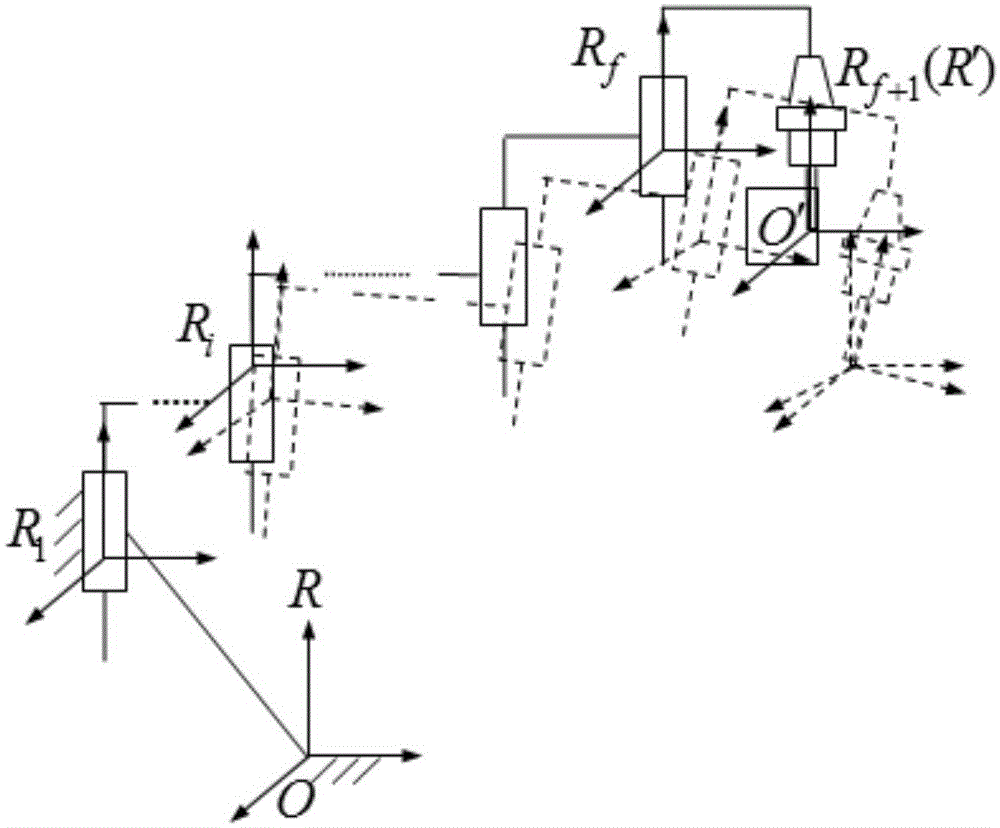

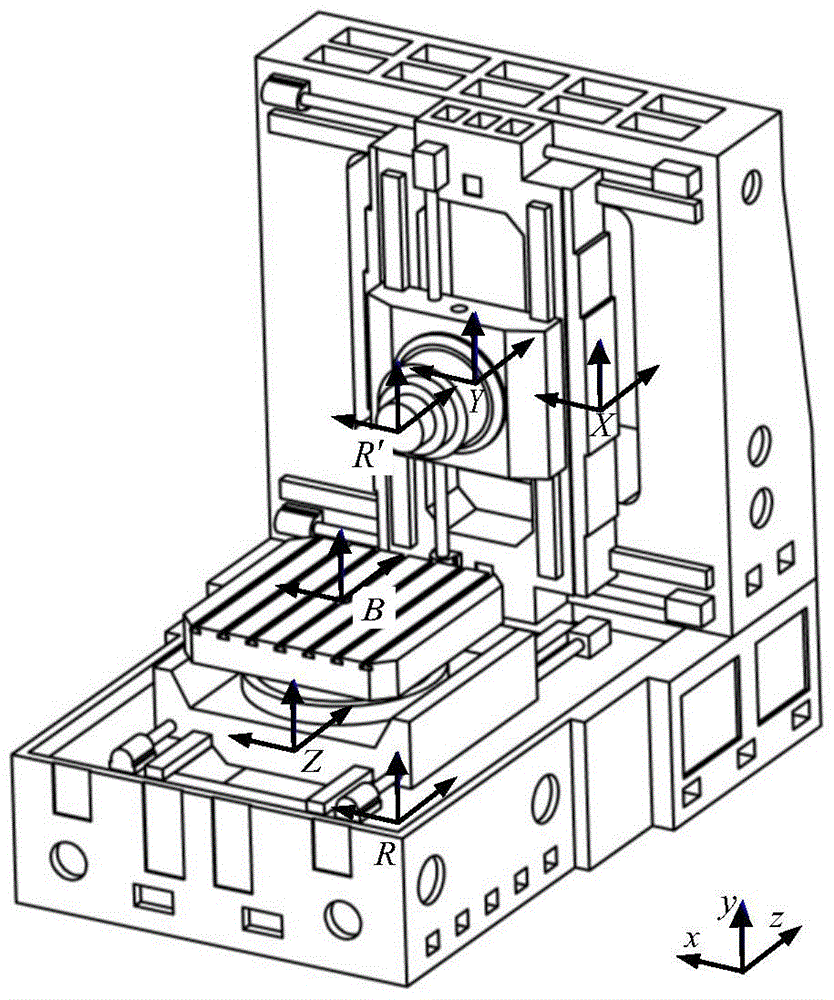

[0032] like figure 1 As shown, the global coordinate system R is established at any point O of the bed, and the instantaneous reference coordinate system R' is established at the reference point O' at the end of the kinematic chain, and R' is always parallel to R. In order to describe the effect of each geometric error source in the kinematic chain on the pose error of the end member of the kinematic chain, a conjoined coordinate system R is established on the i-th kinematic pair reference point i . At the same time, a conjoined coordinate system R is established at O' f+1 , and the kinematic chain is in the initial state when R f+1 Consistent with the R' direction.

[0033] According to the structural characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com