Steam pressure lifting adsorption method and heat pump utilizing same

An adsorption heat pump and adsorption method technology, applied in the field of steam pressure lift adsorption heat pump and steam pressure lift adsorption method, can solve the problems of low output temperature of heat pump, power consumption, large equipment investment, etc., to improve the steam utilization rate, The effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

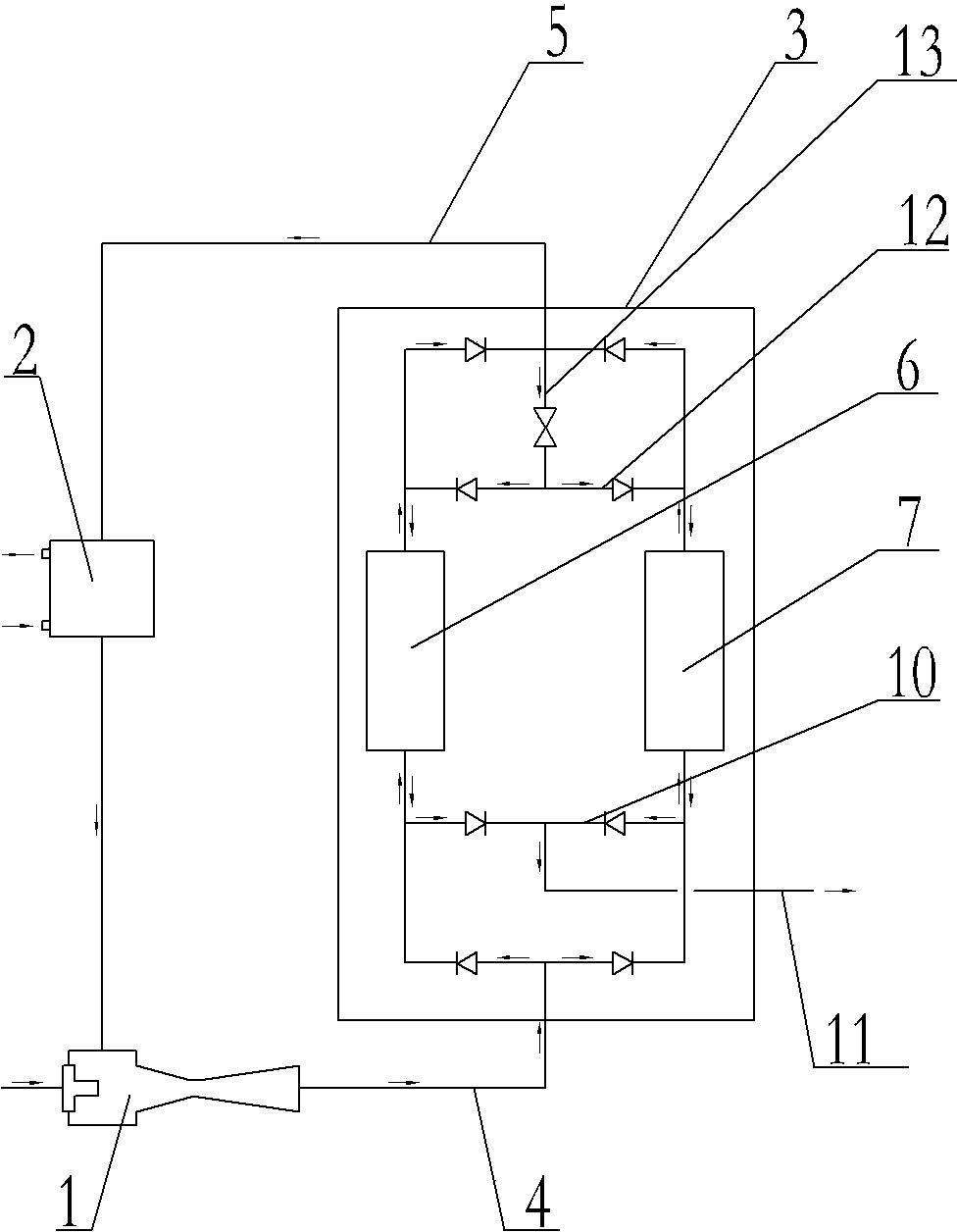

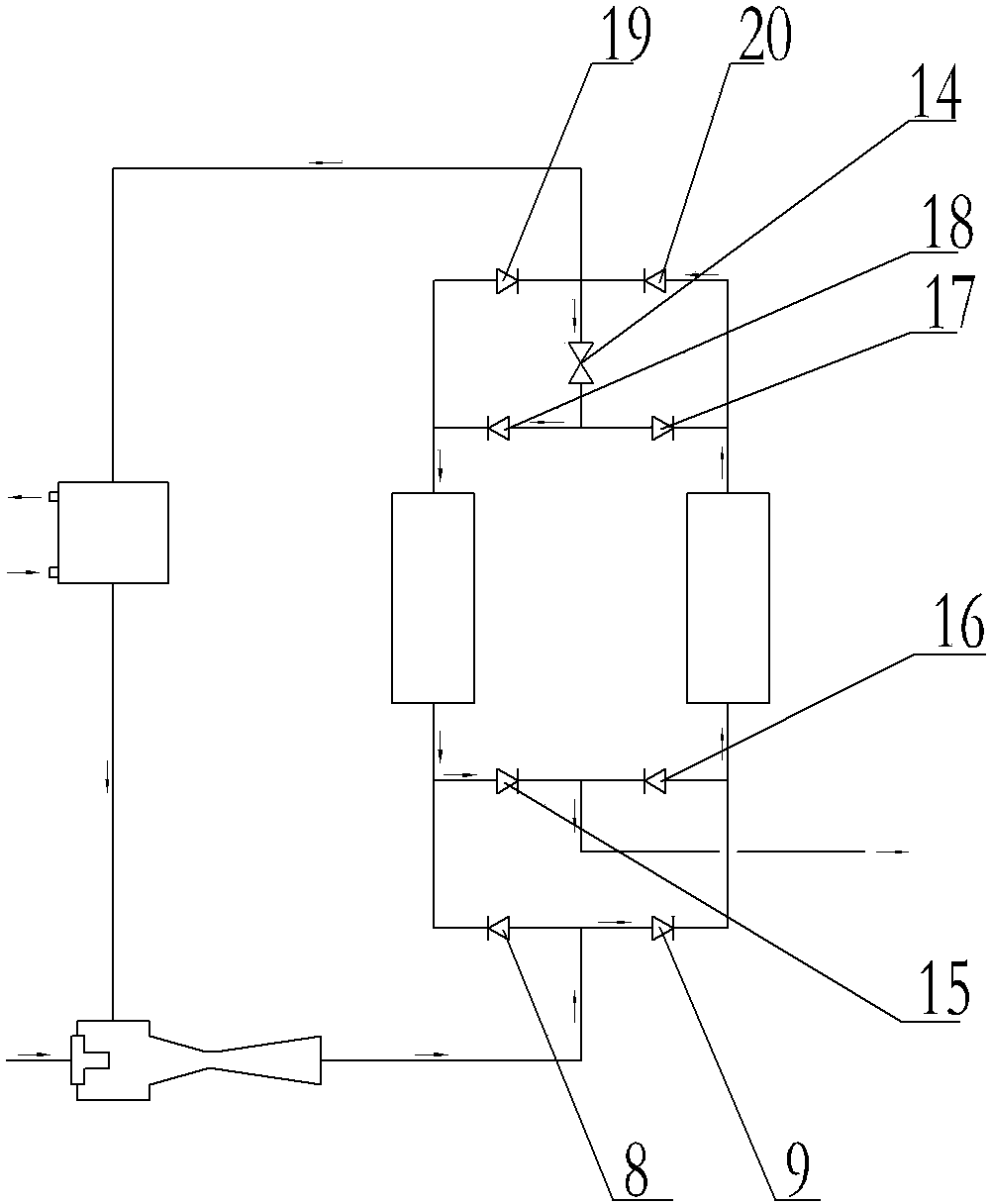

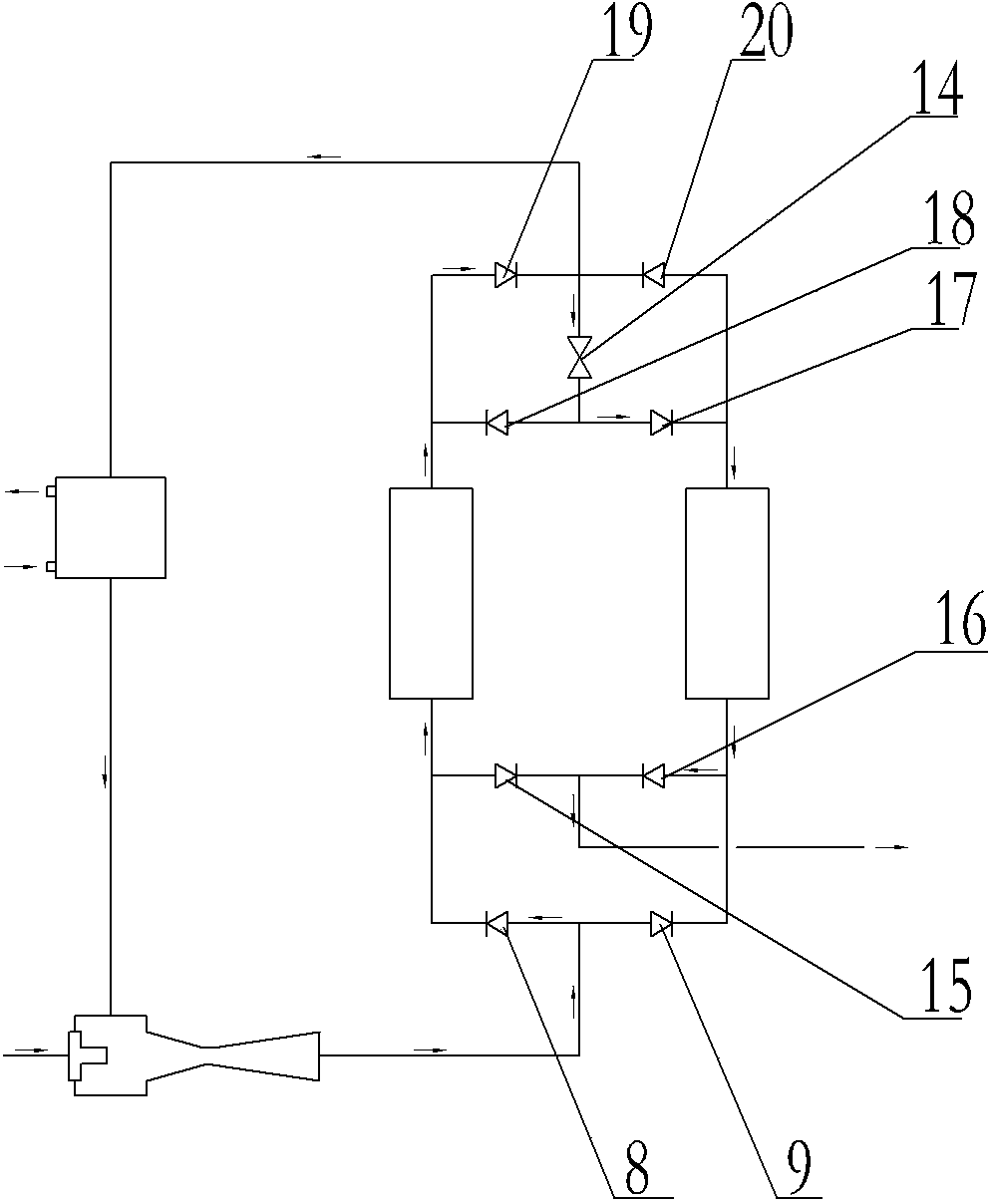

[0015] See Figure 1 ~ Figure 3 , a steam pressure-boosting adsorption heat pump, which includes a steam mixer 1, a heat exchanger 2, and a heating module 3. The steam mixer has a steam mixer inlet, a circulation inlet, and a steam mixer outlet. The steam mixer inlet is connected to the steam through a pipeline. Source connection, the steam mixer outlet is connected to the heating module 3 through the low-temperature pipeline 4, the heating module 3 is an adsorber heating module, and the heat exchanger 2 is provided with a heat exchanger inlet, a heat exchanger outlet, an external medium inlet and an external medium outlet , the inlet of the heat exchanger is connected with the heating module 3 through a high-temperature pipeline 5, and the outlet of the heat exchanger is connected with the circulation inlet on the steam mixer through a pipeline.

[0016] The heating module 3 includes two adsorbers, respectively the left adsorber 6 and the right adsorber 7, the adsorber is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com