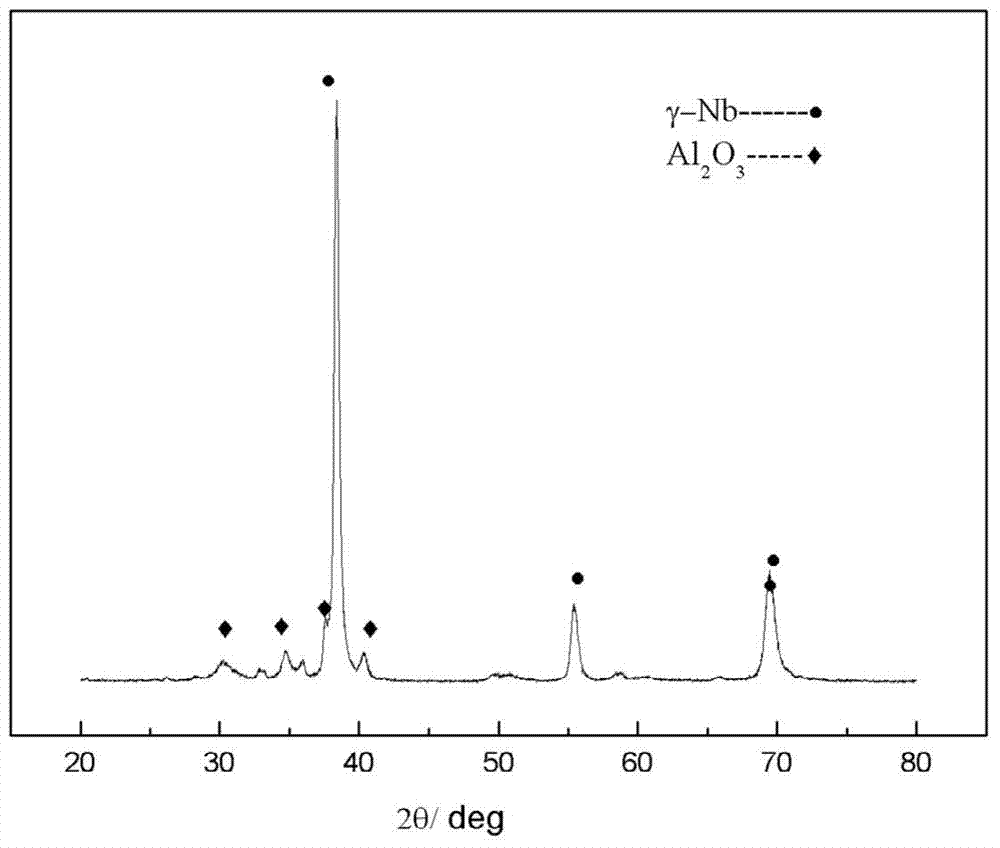

Method for preparing high-temperature composite coating on niobium-based surface by utilizing sol-gel method

A surface sol-gel, niobium-based alloy technology, used in coatings, metal material coating processes, solid-state chemical plating, etc., can solve the problems of coating cracks, different lattice structures, loss of protective matrix, etc. Improved bonding, easy handling, and reduced internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]The method of preparing composite high-temperature coating by sol-gel method on niobium-based surface:

[0046] The first step: pretreatment of niobium-based alloy sample:

[0047] After pre-grinding, the niobium-based alloy samples were cleaned and degreased with absolute ethanol and acetone, and then dried by ultrasonic cleaning.

[0048] The second step: chemical treatment to prepare the intermediate bonding layer of the niobium-based alloy sample:

[0049] The steps of preparing the intermediate bonding layer are as follows:

[0050] 1. Chemical degreasing

[0051] The pretreated niobium-based alloy sample was treated with 15g / L Na 3 PO 4 12H 2 O, 10g / L Na 2 CO 3 and 5g / LNa 2 SiO 3 The formed mixed solution was soaked at a temperature of 50° C. for 4 minutes to obtain a niobium-based alloy sample after removing oil and impurities.

[0052] 2. Acid and alkali erosion

[0053] 1) The niobium-based alloy sample after degreasing and impurity removal was subjec...

Embodiment 2

[0070] The method of preparing composite high-temperature coating by sol-gel method on niobium-based surface:

[0071] The first step: pretreatment of niobium-based alloy sample:

[0072] After pre-grinding, the niobium-based alloy samples were cleaned and degreased with absolute ethanol and acetone, and then dried by ultrasonic cleaning.

[0073] The second step: chemical treatment to prepare the intermediate bonding layer of the niobium-based alloy sample:

[0074] The steps of preparing the intermediate bonding layer are as follows:

[0075] 1. Chemical degreasing

[0076] The pretreated niobium-based alloy sample was treated with 40g / L Na 3 PO 4 12H 2 O, 30g / L Na 2 CO 3 and 15g / L Na 2 SiO 3 The formed mixed solution was soaked at a temperature of 60° C. for 5 minutes to obtain a niobium-based alloy sample after removing oil and impurities.

[0077] 2. Acid and alkali erosion

[0078] 1) The niobium-based alloy sample after degreasing and impurity removal was sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com