Recycling and treatment process and device for waste ceramic by crushing and grinding and pre-mixed concrete

A technology for waste ceramics and processing technology, applied in the field of ready-mixed concrete, can solve the problems of limited number of recycling and environmental pollution of new waste, and achieve the effect of promoting recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

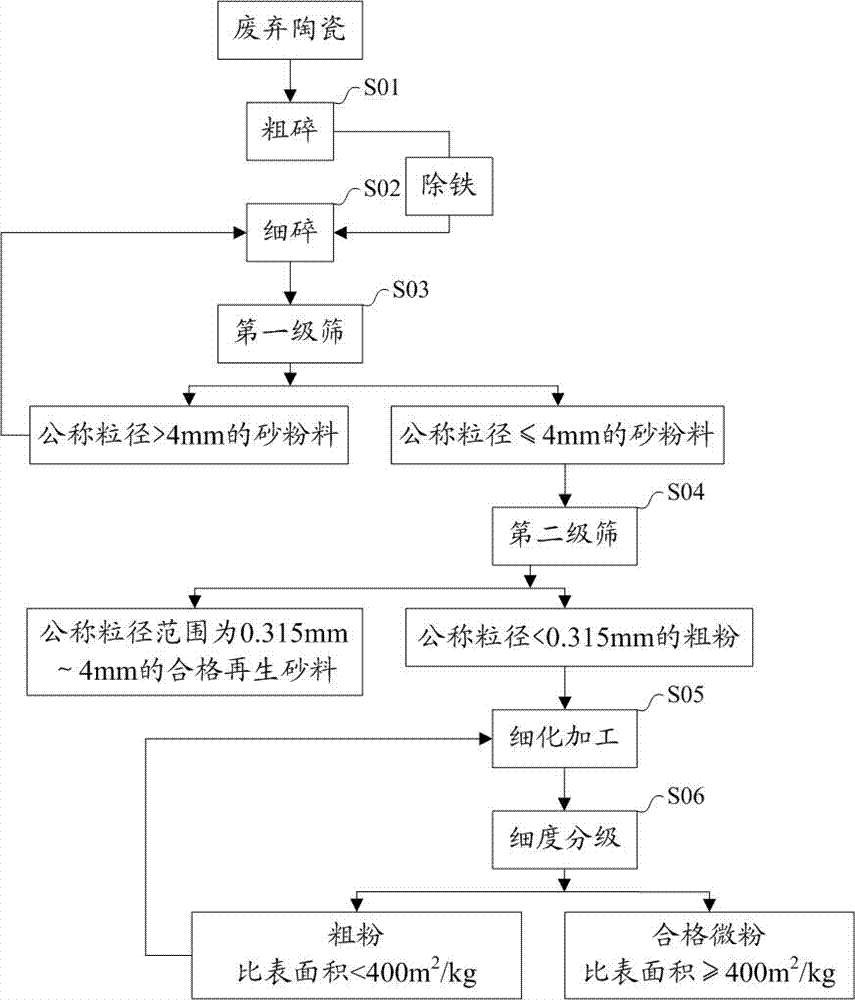

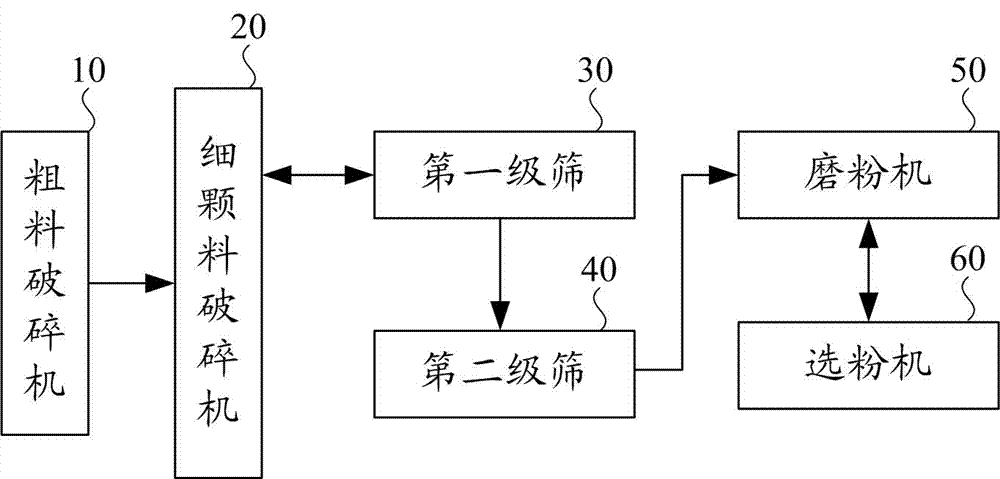

[0035] refer to figure 1 Shown is a schematic flow chart of the waste ceramics crushing, grinding, recycling and processing process of the present invention.

[0036] Use moving tools to transport the waste ceramics from the stockyard to the storage hopper on the working site, and then feed them into the primary crusher for primary crushing S01 by the feeding device. Feed requirements, such as particle size <400mm, and metal impurities should be removed by iron remover.

[0037] Below the output port of the coarse crushing machine, use a conveyor to send the coarsely crushed waste porcelain to the fine particle crusher for fine crushing S02 to form a mixture of sand and coarse powder.

[0038] Pass the obtained mixture of sand and coarse powder through the first-stage sieve S03, so that the sand powder with a nominal particle size ≤ 4mm passes through the sieve, and the unusable sand with a nominal particle size > 4mm is re-input into the fine particle crusher for re-crushing...

Embodiment 2

[0054] The embodiment of the present invention discloses a method for making ready-mixed concrete with a concrete strength grade of C25 by using the qualified sand material and micropowder generated by the waste ceramic crushing, grinding, recycling and utilization process above, and regenerated sand and micropowder replace part of the natural sand and cement gelling agent respectively. The mix ratio of ready-mixed concrete is (unit: kg / m 3 ):

[0055] Cement gelling agent: gravel: sand: water: admixture = 339 (cement 206 + fly ash 72 + micropowder 61):

[0056] 1086: 770 (river sand 385 + recycled sand 385): 175: 6.6 = 1: 3.20: 2.27: 0.52: 0.019

[0057] Among them: recycled sand: total weight of sand = 385: 770 = 0.5: 1

[0058] Micro powder: total weight of gelling agent = 61: 339 = 0.18: 1

Embodiment 3

[0060] The embodiment of the present invention discloses a method for making ready-mixed concrete with a concrete strength grade of C30 by using the qualified sand material and micropowder generated by the waste ceramic crushing, grinding, recycling and utilization process above, and regenerated sand and micropowder replace part of the natural sand and cement gelling agent respectively. The mix ratio of ready-mixed concrete is (unit: kg / m 3 ):

[0061] Cement gelling agent: gravel: sand: water: admixture = 343 (cement 230 + fly ash 78 + micropowder 35):

[0062] 1184: 699 (river sand 559 + recycled sand 140): 168: 6.52 = 1: 3.45: 2.04: 0.49: 0.019

[0063] Among them: recycled sand: total weight of sand = 140: 699 = 0.20: 1

[0064] Micropowder: total weight of gelling agent = 35:343 = 0.102:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com