Nail gun

A nail gun and nail needle technology, applied in the field of nail guns, can solve problems such as forgetting to adjust, firing two nail needles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The structural features and expected effects of the present invention will be described below with preferred embodiments, but they are not intended to limit the scope of protection of the present invention, and will be described first.

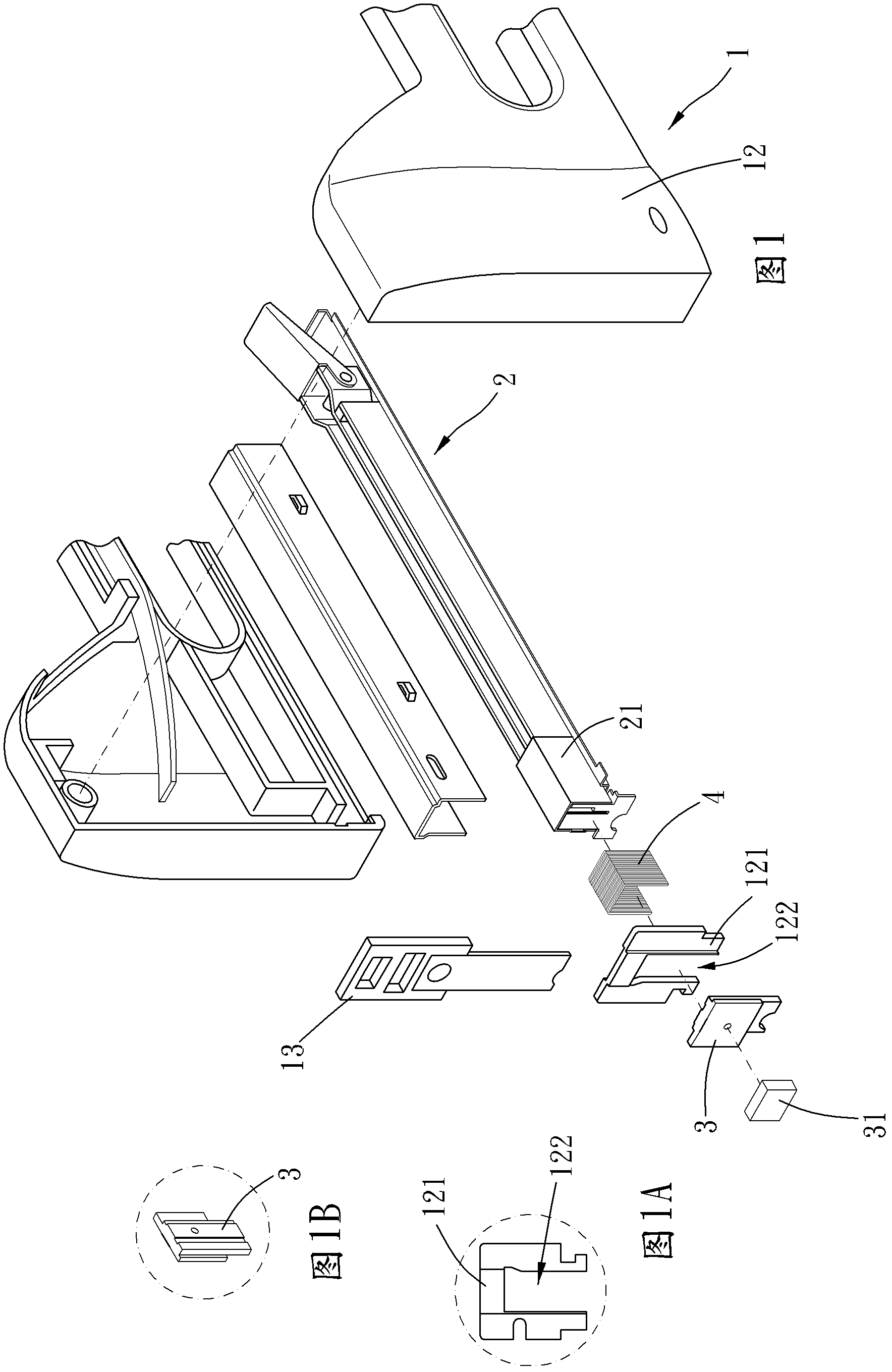

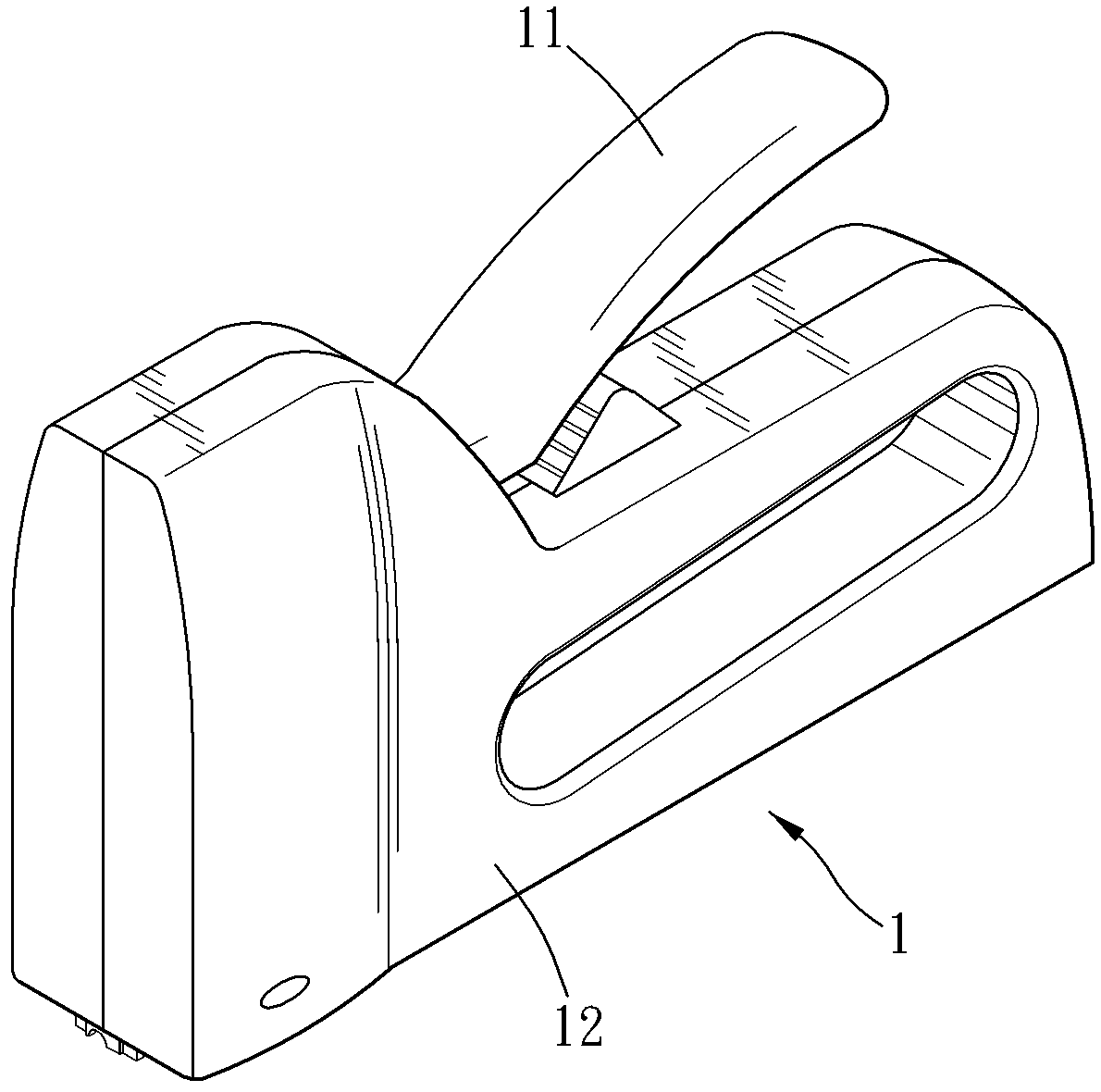

[0036] Please refer to Figure 1 to Figure 2 , The nail gun of the present invention includes a body 1 , a nail magazine 2 and an adjustment part 3 .

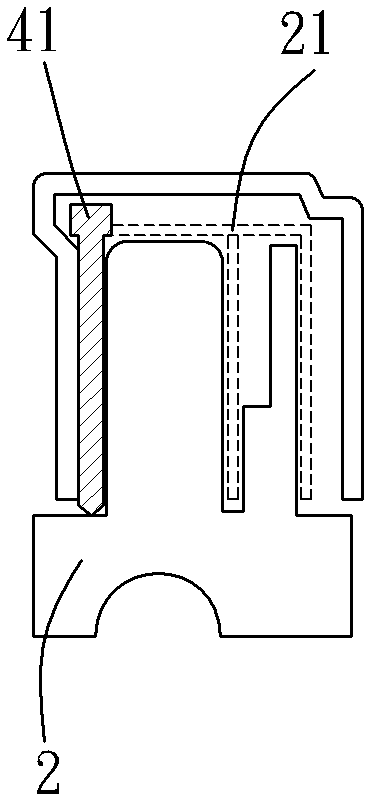

[0037] The body 1 includes a pressing member 11, a casing 12, a striking plate 13 and a stopper. The casing 12 is provided with a nailing groove, and the striking plate 13 can move along the nailing groove, that is, the striking plate 13 It can slide relative to the shell 12; when the pressing piece 11 moves relative to the shell 12, the detent part will drive the striking plate 13 to move in one direction along the nailing groove to produce a firing effect, so the pressing piece 11 is As a switch for controlling firing; the catch part is used to drive the striking plate 13 to move, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com