A fuel input actuating device and a gas power tool with the device

An actuating device, fuel input technology, applied in combustion engines, internal combustion piston engines, liquid fuel feeders, etc., can solve problems such as difficult analysis and resolution, waste, and inability to observe the working conditions of fuel storage tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

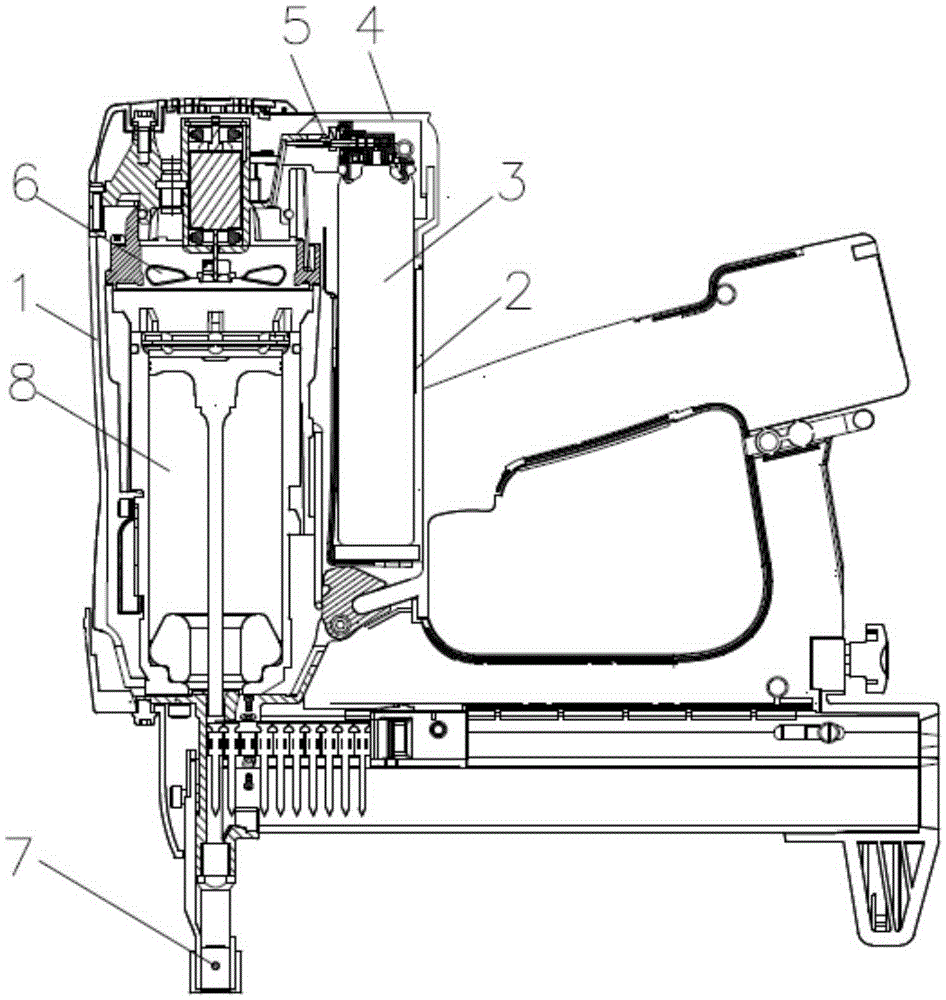

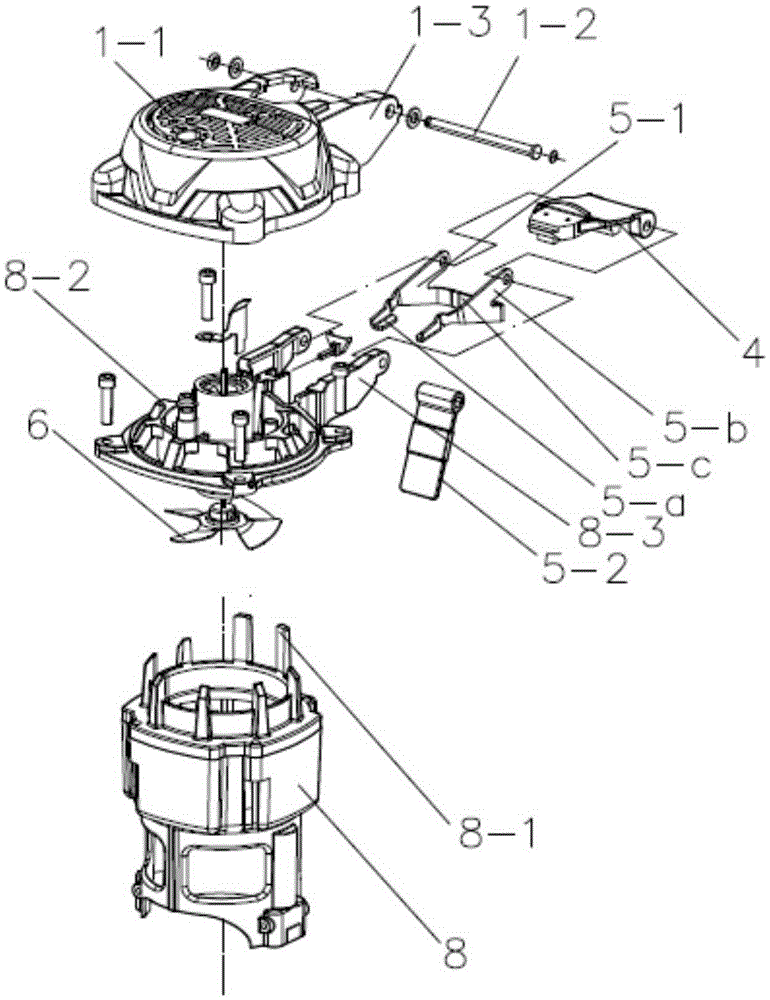

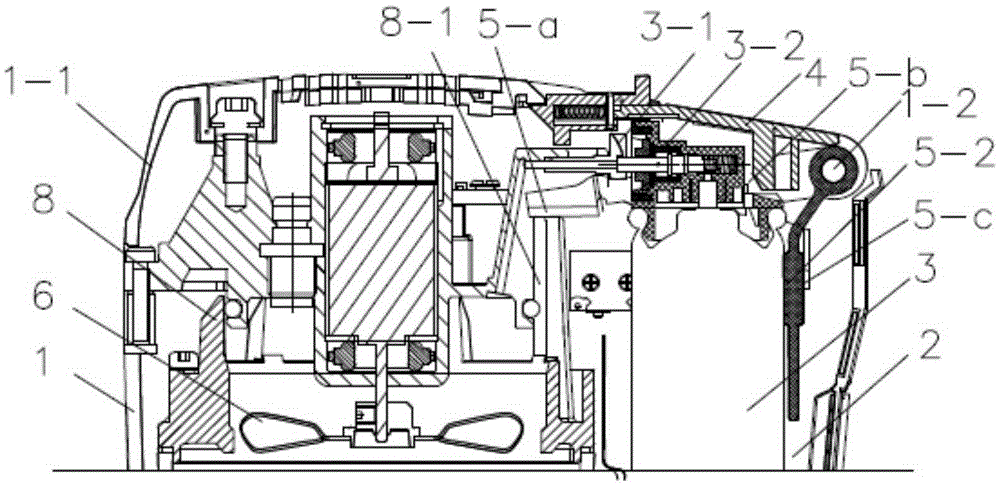

[0017] The basic structure of the fuel input actuator of this embodiment is as follows: figure 2 , image 3 with Figure 4 As shown, the rear cover 1-1 fixedly connected with the casing 1 and the combustion chamber cover 8-2 fixedly connected with the combustion chamber 8 respectively extend a pair of hinge lugs 1-3 and 8-3 toward the fuel chamber top, and the fuel chamber The cover 4 is simultaneously hinged on the hinge lugs 1-3 and 8-3 above the fuel chamber of the gas power tool casing through the hinge shaft 1-2, and the push plate 5-1 is also coaxially hinged through the hinge shaft 1-2 As for the hinge lugs 1-3 and 8-3, the hinge support is more secure and reliable with the help of this double support structure. The push plate 5-1 has a pair of lever arms 5-b respectively extending from both sides around the quantitative valve above the fuel storage tank towards the direction of the combustion chamber. A pair of push rods 8-1 extend upwards from the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com