Electroosmosis sludge modifying and drying device

An electro-osmosis and sludge technology, applied in the field of drying device and electro-osmotic sludge modification drying device, can solve the problems of the anode roller not working normally, being naked in the frame, and the conveyor chain being loose, etc. Eliminate sparks, increase productivity, increase the effect of meshing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

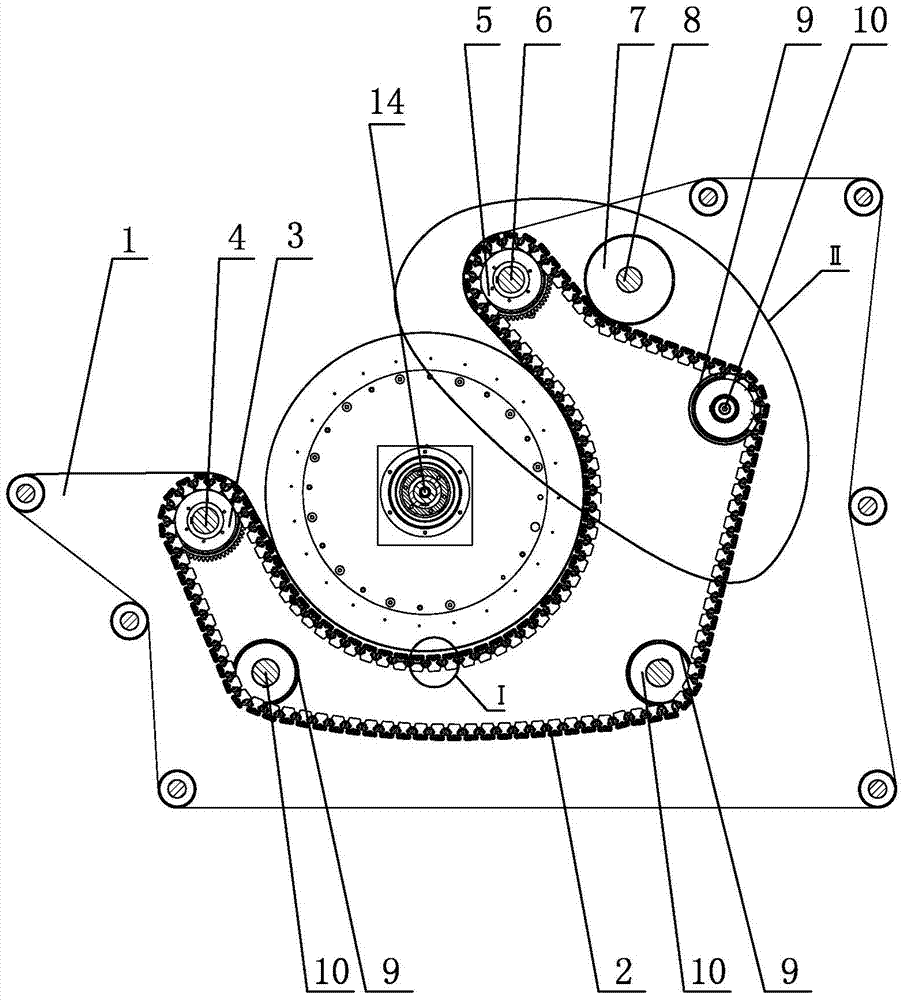

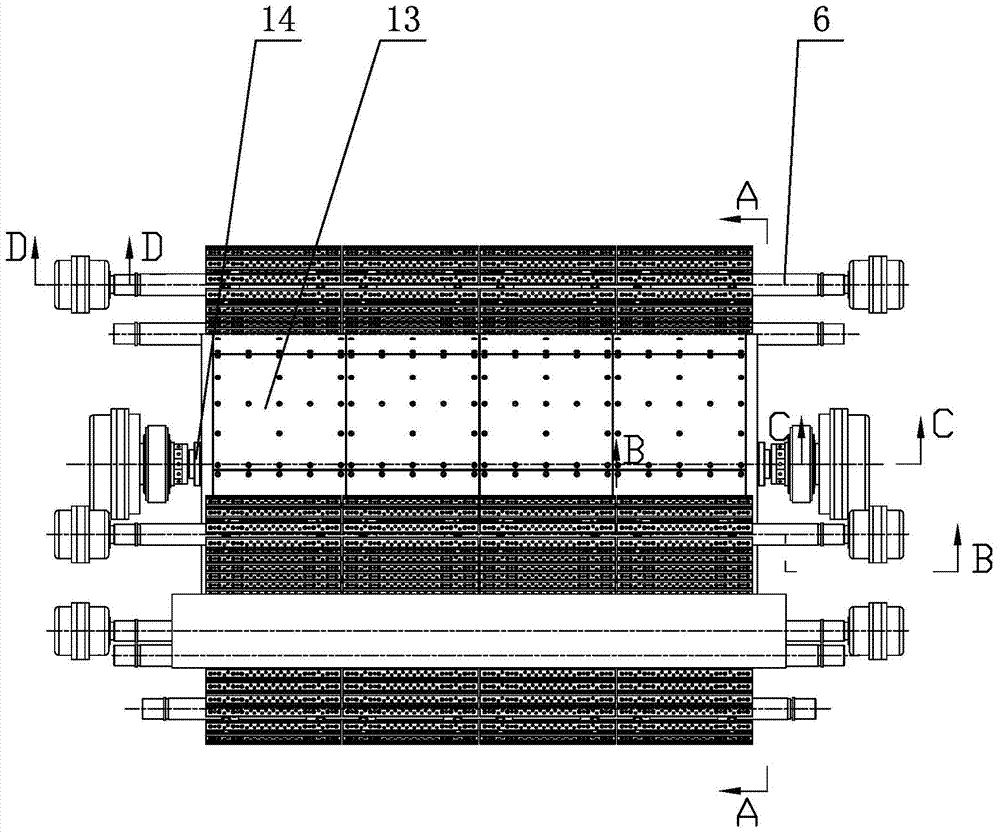

[0007] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment. The electroosmotic sludge modification and drying device described in this embodiment includes a frame 1, an anode roller assembly, a plurality of conveying chains 2, a plurality of driving sprockets 3, a driving shaft 4, and a plurality of driven chains Wheel 5, driven shaft 6, conductive resistance roller 7, conductive resistance shaft 8, two anode power distribution assemblies, multiple guide wheels 9, three guide shafts 10, six cathode power distribution assemblies, multiple shorts sheet 11 and a plurality of cathode filter plates 12, the driving shaft 4 is installed on the left side of the middle part of the frame 1, a plurality of driving sprockets 3 are set on the driving shaft 4, and the driven shaft 6 is installed on the upper part of the frame 1, and a plurality of The driven sprocket 5 is sleeved on the driven shaft 6, a guide shaft 10 is respectively installed on the le...

specific Embodiment approach 2

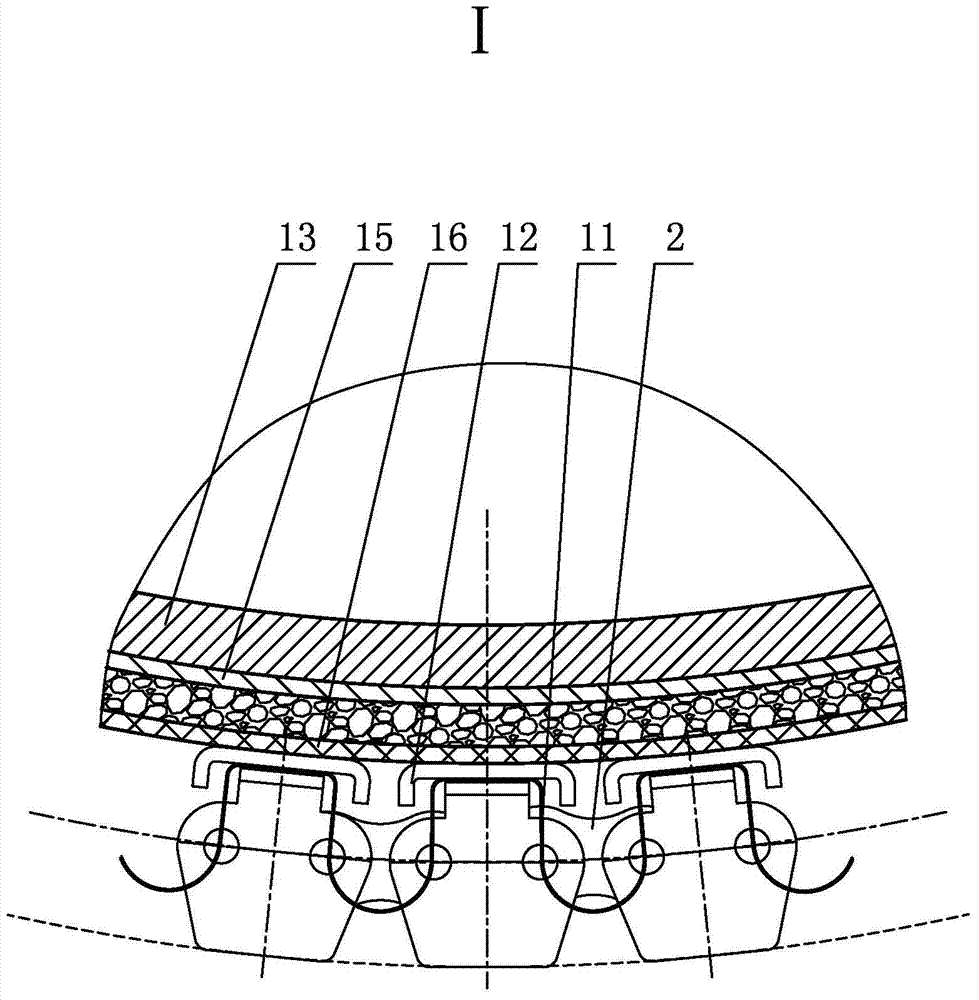

[0009] Specific implementation mode two: combination figure 1 and image 3 Describe this embodiment, the anode roller assembly of the electroosmotic sludge modification and drying device described in this embodiment includes an anode roller 13, an anode roller shaft 14, an anode electrode plate 15 and a filter belt 16, and the anode roller shaft 14 is installed on the frame 1, the anode roll 13 is set on the anode roll shaft 14, the anode electrode plate 15 and the filter belt 16 are set on the outer wall of the anode roll 13 from inside to outside in turn, and the outer wall of the filter belt 16 is connected to the inner side of the conveyor chain 2 A plurality of cathode filter plates 12 are in contact. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and image 3 To illustrate this embodiment, the surface of the anode electrode plate 15 of the electroosmotic sludge modification and drying device described in this embodiment is coated with an insoluble conductive paint.

[0011] The technical effect of this embodiment is: so set, the surface activity of the anode electrode plate 15 is greater than that of other materials, thereby increasing the electrochemical reaction rate, thereby increasing the productivity, and making the heavy metal content of the processed sludge consistent. The anode electrode plate 15 is installed in detachable blocks. When the insoluble conductive coating loses its activity, the anode electrode plate 15 can be replaced at any time. The replaced anode electrode plate 15 can be coated with the insoluble conductive paint on the air surface again to make it more Repeated use saves the sheet material of the anode electrode plate 15. Other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com