Multifunctional catalyst for methane steam reforming hydrogen production and preparation method thereof

A technology for producing hydrogen from methane steam and reforming, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Catalytic activity, good absorption effect, stable absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

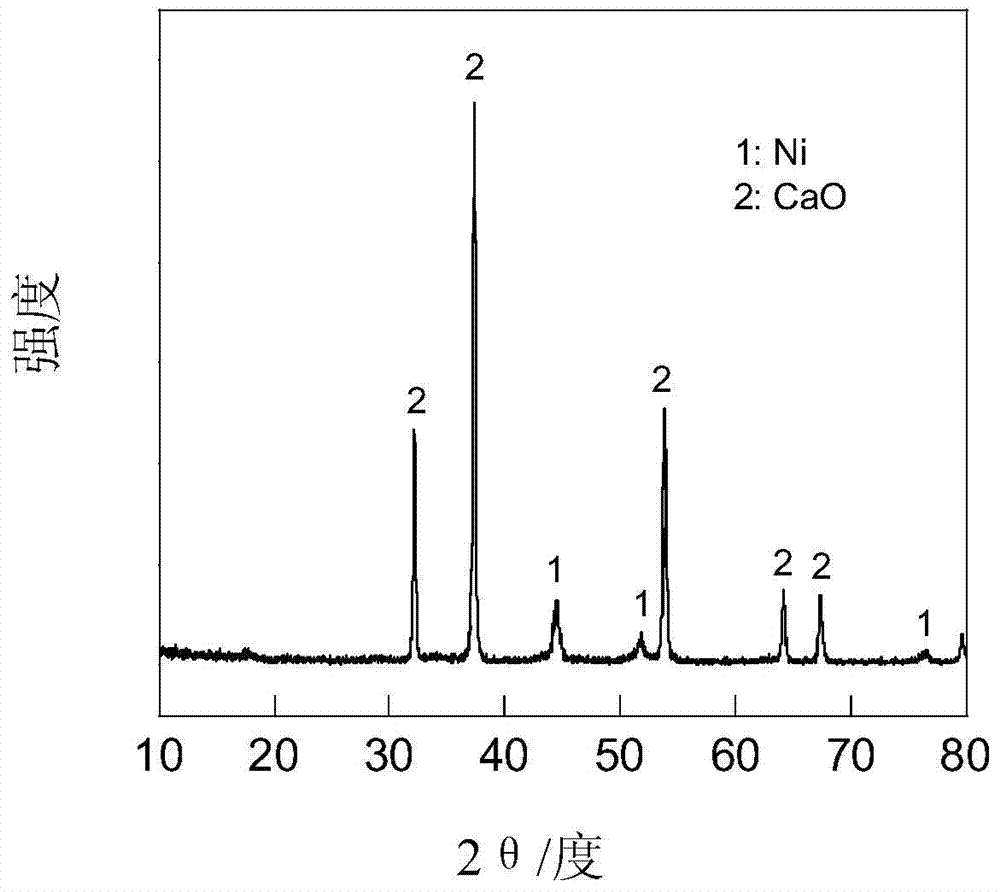

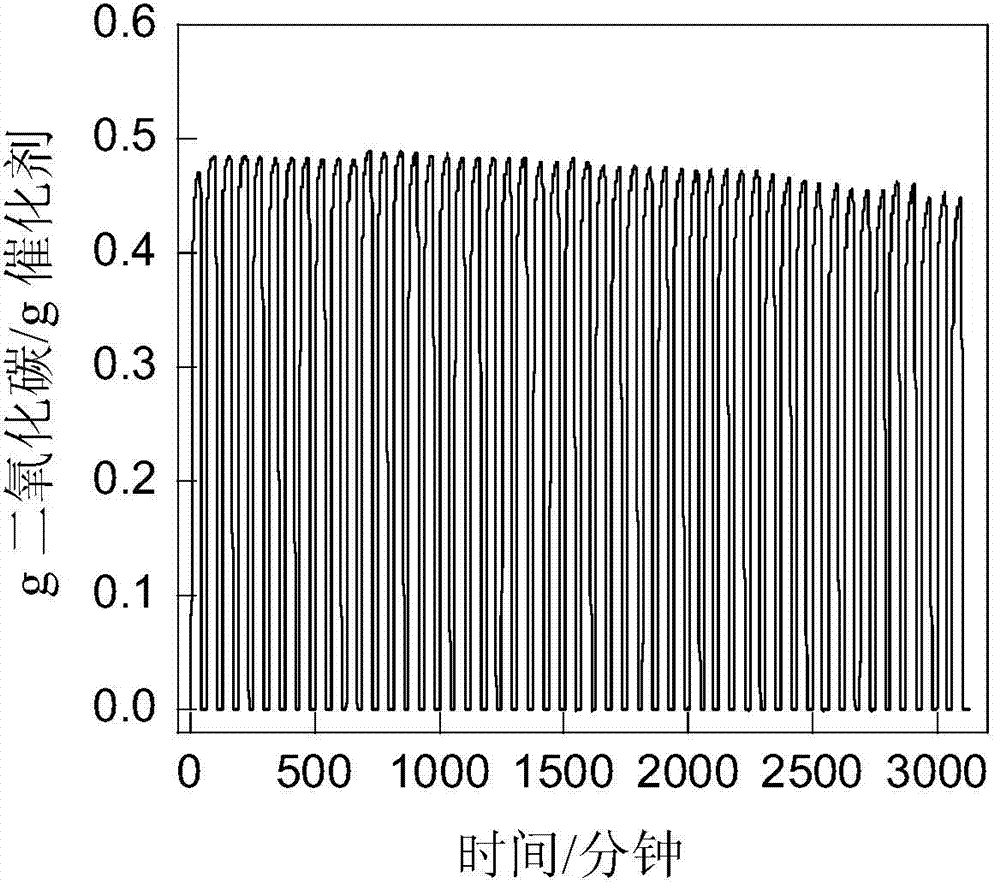

Embodiment 1

[0029] Add 19mL of deionized water into the three-necked flask, then add 4.421g of citric acid (the molar ratio of water to citric acid is 50:1), weigh 2.340g of L-calcium lactate, 1.702g of aluminum isopropoxide powder and 0.468g of six Add nickel nitrate water into the above solution, the molar ratio of metal ion to citric acid is 1:1.2, stir at 85°C for 2h (500r / min), measure quantitative ethylene glycol (ethylene glycol and citric acid molar The ratio is 2:1) into the above mixed solution, and adjust the pH of the mixed solution to between 1-2 with nitric acid. Finally, raise the temperature to 105°C, stir and reflux under the temperature adjustment for 6 hours, stir and evaporate the above sol in the range of 85-95°C to form a gel, then pour the gel into a watch glass and put it in an oven at 110°C After drying, the dried solid was ground into powder with a mortar, and then placed in a muffle furnace for calcination at 800°C for 4 hours to obtain multifunctional catalyst ...

Embodiment 2

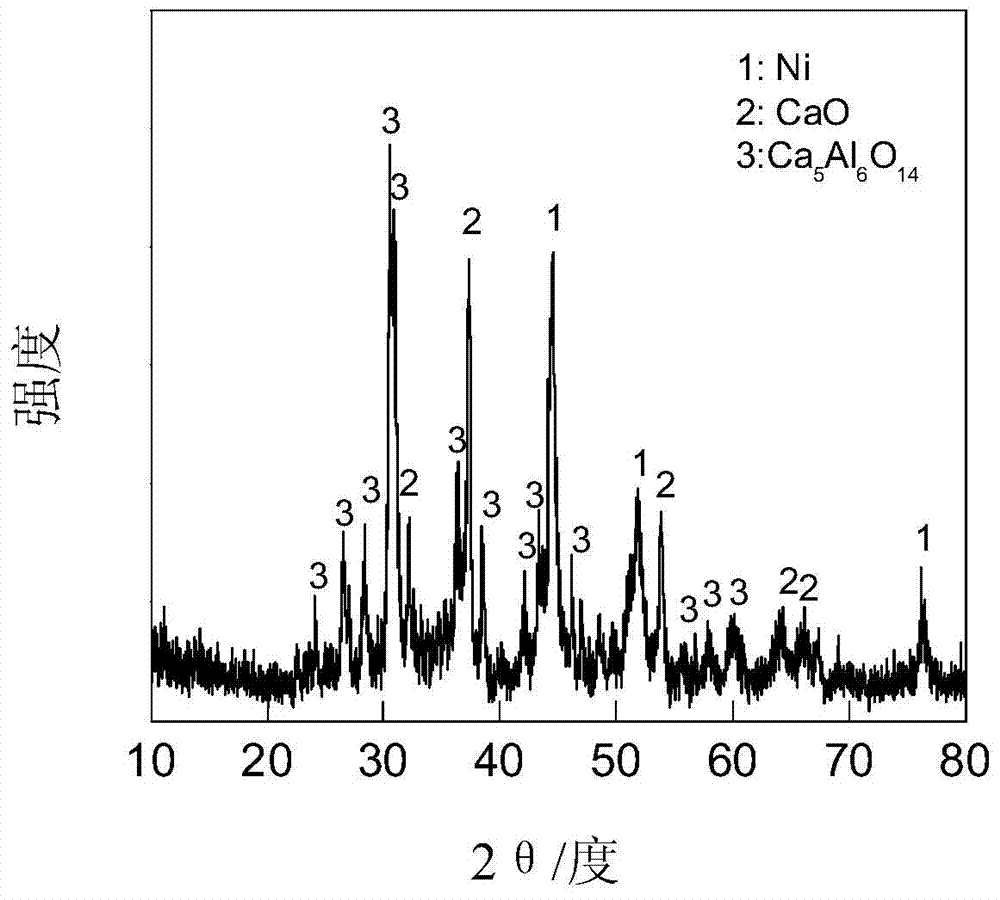

[0031] Add 68mL of deionized water into the three-neck flask, then add 15.884g of citric acid (the molar ratio of water to citric acid is 50:1), weigh 14.096g of L-calcium lactate, 1.702g of aluminum isopropoxide powder and 2.610g of six Add nickel nitrate in water to the above solution, the molar ratio of metal ion to citric acid is 1:1.2, stir at 85°C for 2h (600r / min), measure quantitative ethylene glycol (ethylene glycol and citric acid molar The ratio is 2:1) into the above mixed solution, and adjust the pH of the mixed solution to between 1-2 with nitric acid. Finally, raise the temperature to 105°C, stir and reflux under the temperature adjustment for 6 hours, stir and evaporate the above sol in the range of 85-95°C to form a gel, then pour the gel into a watch glass and put it in an oven at 110°C After drying, the dried solid was ground into powder with a mortar, and then placed in a muffle furnace for calcination at 850°C for 2 hours to obtain multifunctional catalyst...

Embodiment 3

[0033] Add 133mL of deionized water into the three-necked flask, then add 30.990g of citric acid (the molar ratio of water to citric acid is 50:1), weigh 28.070g of L-calcium lactate, 1.702g of aluminum isopropoxide powder and 6.842g of six Nickel nitrate in water was added to the above solution, the molar ratio of metal ions to citric acid was 1:1.2, stirred at 85°C for 2 hours (700r / min), and a quantitative amount of ethylene glycol (ethylene glycol and citric acid moles The ratio is 2:1) into the above mixed solution, and adjust the pH of the mixed solution to between 1-2 with nitric acid. Finally, heat up to 105°C, stir and reflux for 6 hours under the temperature adjustment, stir and evaporate the above sol in the range of 85-95°C to form a gel, then pour the gel into a watch glass and put it in an oven at 100°C After drying, the dried solid was ground into powder with a mortar, and then placed in a muffle furnace and calcined at 900° C. for 1.5 h to obtain the multifunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com