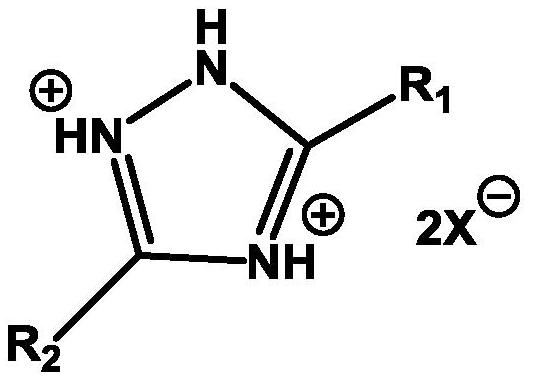

Multi-site triazole ionic liquid capable of efficiently and reversibly absorbing ammonia gas

A technology of ionic liquids and triazoles, which is applied in gas treatment, separation method, dispersed particle separation, etc., to achieve the effect of simple synthesis process, convenient large-scale preparation and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Dissolve 0.1mol of 1,2,4-triazole (6.907g) in 80mL of deionized water, and add the 1,2,4-triazole aqueous solution into a round-bottomed flask in an ice bath, Then, 0.2 mol (19.415 g) of 65% nitric acid solution was slowly added dropwise, and after the dropwise addition was completed, the reaction was stirred with magnetic force for 48 hours. After the reaction finishes, heating and rotating to remove residual nitric acid and water, and vacuum drying at 60°C to obtain [TrizH 2 ][NO 3 ] 2 .

[0016] 2) Dissolve 0.1mol of 1,2,4-triazole (6.907g) in 80mL of absolute ethanol, and add the 1,2,4-triazole absolute ethanol solution into a round bottom flask and place In an ice bath, 0.2 mol (30.14 g) trifluoromethanesulfonic acid was slowly added dropwise. After the dropwise addition was completed, the reaction was stirred by magnetic force for 48 hours. After the completion of the reaction, heat and rotate to remove residual trifluoromethanesulfonic acid and dehydrated ...

Embodiment 2

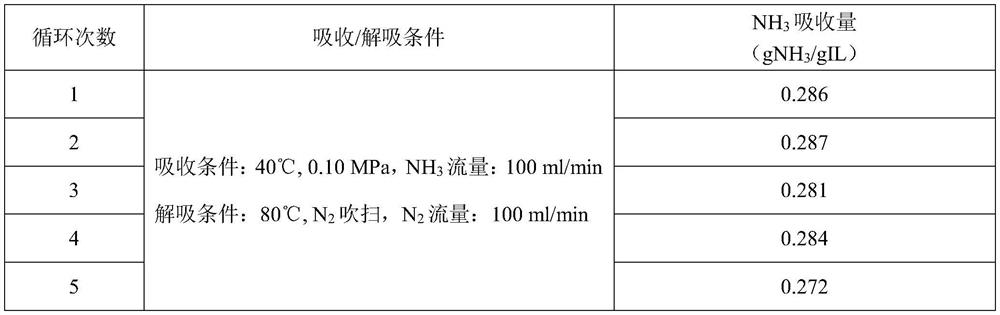

[0019] In the self-made absorption bottle that inner diameter is 2.00cm, add 3.00g embodiment 1 1) synthesized ionic liquid [TrizH 2 ][NO 3 ] 2 , and then into the NH 3 , the gas flow rate is 100ml / min, the temperature is 40°C, and the pressure is 0.10MPa. Weigh the absorption bottle at regular intervals until the mass does not change. 3 The absorption capacity is 0.287gNH 3 / gIL.

Embodiment 3

[0021] In the self-made absorption bottle that inner diameter is 2.00cm, add 3.00g embodiment 1 2) synthesized ionic liquid [TrizH 2 ][CF 3SO 3 ] 2 , and then into the NH 3 , the gas flow rate is 100ml / min, the temperature is 40°C, and the pressure is 0.10MPa. Weigh the absorption bottle at regular intervals until the mass does not change. 3 The absorption capacity is 0.233gNH 3 / gIL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com