Method for removing SO2 and NOX in combustion coal flue gas through corona discharge and liquid phase oxidation

A technology of corona discharge and coal-fired flue gas, which is applied in the field of flue gas purification, can solve the problems of catalysts such as poor sulfur resistance and water resistance, expensive catalysts, easy poisoning and deactivation of ammonia, etc., to increase the effect of electromigration, Great practical value, low investment and operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

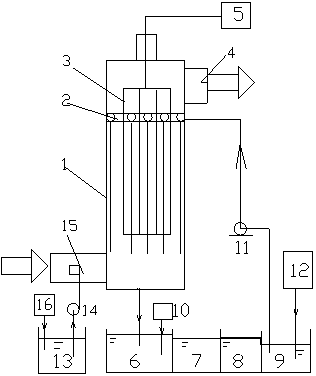

Image

Examples

Embodiment 1

[0032] A company has its own 15-ton coal-fired fluidized furnace, with a coal-fired flue gas volume of 45,000m 3 / h, flue gas SO 2 The concentration is 2030mg / m 3 , flue gas NO X The concentration is 350mg / m 3 , the original use of lime slurry water with a concentration of 10% and spray towers for flue gas dust removal, desulfurization and denitrification, the actual operating water-gas ratio is large, up to 10L / m 3 , the desulfurization efficiency is 85.2%, and the denitrification efficiency is 15.2%. The flue gas desulfurization and denitrification system has problems such as lime slurry blocking pipes and scaling, which seriously affect the normal operation of the desulfurization system, and there are problems such as high desulfurization operating costs. After the transformation, the original tower body is retained, and the combined simultaneous desulfurization and denitrification process of corona discharge and liquid phase oxidation is adopted, and the operating wate...

Embodiment 2

[0034] A company has its own 10-ton coal throwing furnace, with a coal-fired flue gas volume of 35,000m 3 / h, flue gas SO 2 The concentration is 2300mg / m 3 , flue gas NO X The concentration is 405mg / m 3 , the original use of lime slurry water with a concentration of 15% and spray towers for flue gas dust removal, desulfurization and denitrification, the actual operating water-gas ratio is large, up to 12L / m 3 , the desulfurization efficiency is 83.2%, and the denitrification efficiency is 16.6%. The flue gas desulfurization and denitrification system has problems such as lime slurry blocking pipes and scaling, which seriously affect the normal operation of the desulfurization system, and there are problems such as high desulfurization operating costs. After the transformation, the original tower body is retained, and the combined simultaneous desulfurization and denitrification process of corona discharge and liquid phase oxidation is adopted, and the operating water-gas r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com