Tooth repair resin with X-ray radiation resistance and preparation method thereof

A radiation-resistant dental and X-ray technology, applied in the field of dental restoration resin and its preparation, can solve the problems of reducing the mechanical properties of the resin, and achieve the effect of avoiding the problem of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

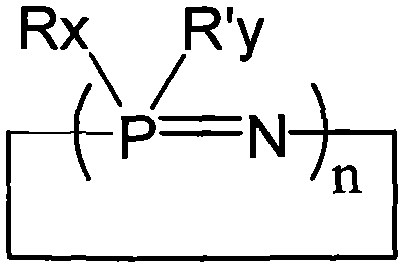

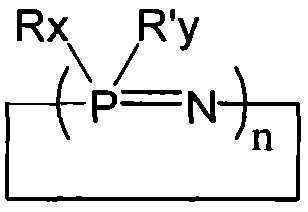

Method used

Image

Examples

Embodiment 1

[0028] Hexachlorocyclotriphosphazene (3.50g) was dissolved in dry tetrahydrofuran (333ml), triethylamine (6.06g) was added, and then hydroxyethyl methacrylate (1.30g) was slowly added dropwise to the system. , heated in a water bath to 25-40°C, and reacted for 12-24 hours; slowly added 4-iodoaniline (10.95g) to the system, and continued the reaction for 48-96 hours; filtered to remove insoluble matter, and rotary evaporated to remove part of the solvent to obtain a viscous The liquid was precipitated with deionized water, soaked and cleaned, and freeze-dried to obtain a cyclic triphosphazene (IHCP01) co-substituted by hydroxyethyl methacrylate and 4-iodoaniline. through 1 According to H NMR detection, the ratio of hydroxyethyl methacrylate and 4-iodoaniline substituents is 1:5.

[0029] IHCP01 (0.25g) was dissolved in TEGDMA (2.375g), CQ (0.025g) and DMAEMA (0.025g) were added, then Bis-GMA (2.375g) was added and mixed well. The mixed resin was injected into the mold, irradi...

Embodiment 2

[0031] Hexachlorocyclotriphosphazene (3.50g) was dissolved in dry tetrahydrofuran (250ml), triethylamine (6.06g) was added, and then hydroxyethyl methacrylate (2.60g) was slowly added dropwise to the system. , heated in a water bath to 25-40°C, reacted for 12-48 hours; slowly added 3,4-diiodoaniline (13.8g) to the system, and continued to react for 72 hours; filtered to remove insoluble matter, rotary evaporation to remove part of the solvent to obtain a viscous Precipitate with deionized water, soak and wash, and freeze-dry to obtain cyclic triphosphazene (IHCP02) co-substituted by hydroxyethyl methacrylate and 3,4-iodoaniline. through 1 According to H NMR detection, the ratio of hydroxyethyl methacrylate to 3,4-iodoaniline substituents is 2:4.

[0032] IHCP02 (0.5g) was dissolved in TEGDMA (2.25g), CQ (0.03g) and DMAEMA (0.03g) were added, then Bis-GMA (2.25g) was added and mixed well. The mixed resin was injected into the mold, irradiated with a dental curing lamp for 120...

Embodiment 3

[0034] Hexachlorocyclotriphosphazene (3.50g) was dissolved in tetrahydrofuran (200ml), triethylamine (6.06g) was added, and then hydroxyethyl methacrylate (3.90g) was slowly added dropwise to the system. , heated in a water bath to 25-40°C, and reacted for 12-48 hours; slowly added 3,4,5-triiodoaniline (14.13g) to the system, and continued to react for 48-96 hours; filtered to remove insoluble matter, and rotary evaporation to remove part The solvent was used to obtain a viscous liquid, which was precipitated with deionized water, soaked and washed, and freeze-dried to obtain hydroxyethyl methacrylate and cyclic triphosphazene (IHCP03) co-substituted by 3,4,5-iodoaniline. through 1 H NMR detection shows that the ratio of hydroxyethyl methacrylate to 3,4,5-iodoaniline substituents is 3:3.

[0035] IHCP03 (0.75g) was dissolved in TEGDMA (2.125g), CQ (0.03g) and DMAEMA (0.03g) were added, then Bis-GMA (2.125g) was added and mixed well. The mixed resin was injected into the mold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com