Absorption core production technology

A production process and technology of absorbent cores, applied in the field of disposable absorbent articles, can solve the problems of increased production cost, unfavorable production activities, long process flow, etc., and achieve the effects of comprehensive dispersing, good dispersing effect, and stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

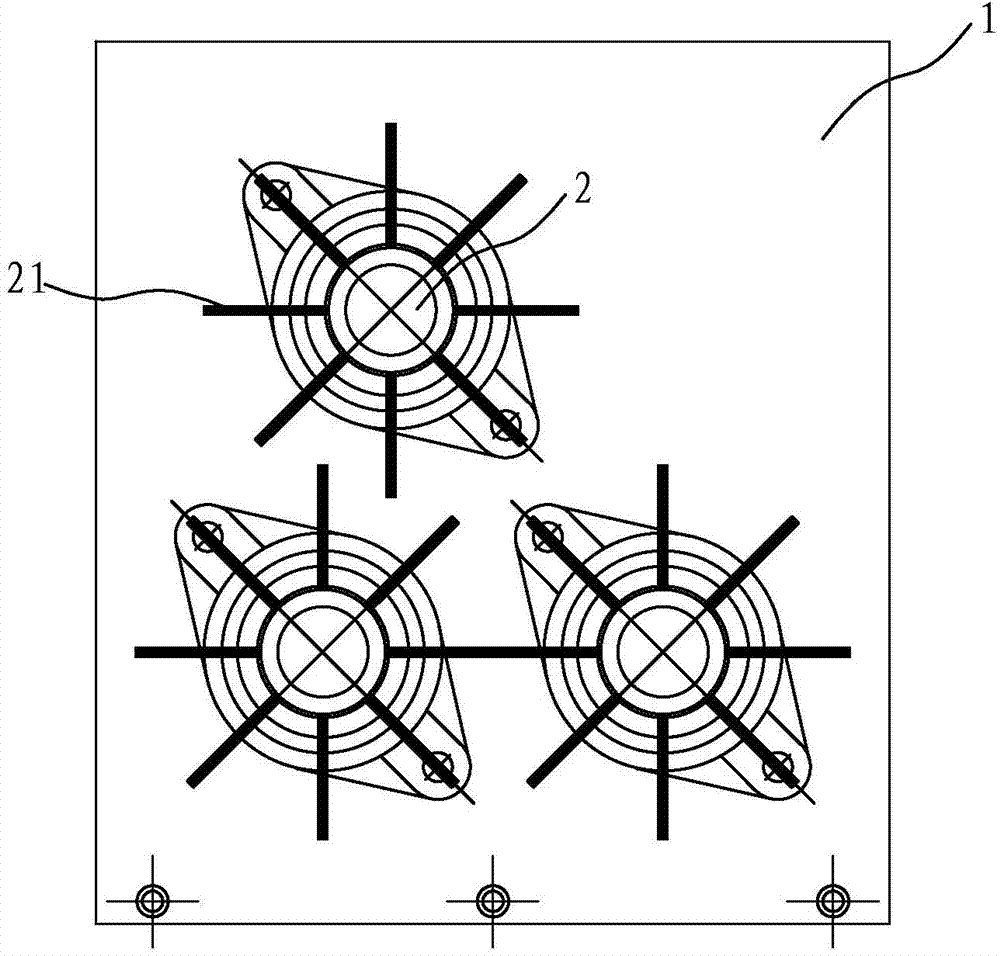

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0024] refer to figure 1 , figure 2 , image 3 , the present embodiment provides an absorbent core production process, comprising the following steps:

[0025] In the first step, the raw materials are input into the pulverizer for pulverization, and the pulverized fluff pulp is output;

[0026] In the second step, the fluff pulp pulverized by the pulverizer is input into the cavity mold wheel device, and polymer materials are added for molding;

[0027] The third step is to absorb the cotton core formed by the mold wheel device through the transfer adsorption device, and transfer it to the conveyor belt for transportation;

[0028] In the fourth step, during the conveying process, a layer of non-woven fabric is covered on the upper part of the cotton core, and a layer of PE film is covered on the bottom of the cotton core, and the cotton core is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com