Anti-dry glass electric kettle

An electric kettle and anti-dry technology, applied in the direction of boiling water appliances, etc., can solve problems such as circuit control failure, glass kettle cracking, safety accidents, etc., achieve the effect of simple and compact structure, improve safety level, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

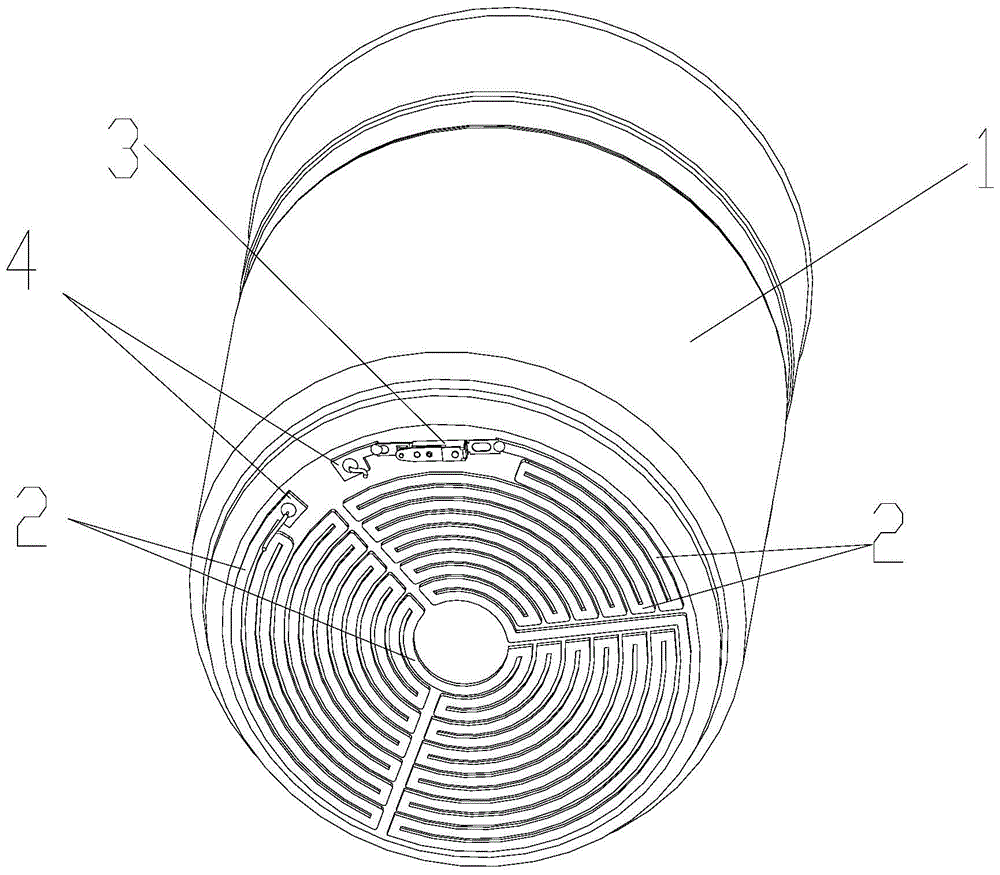

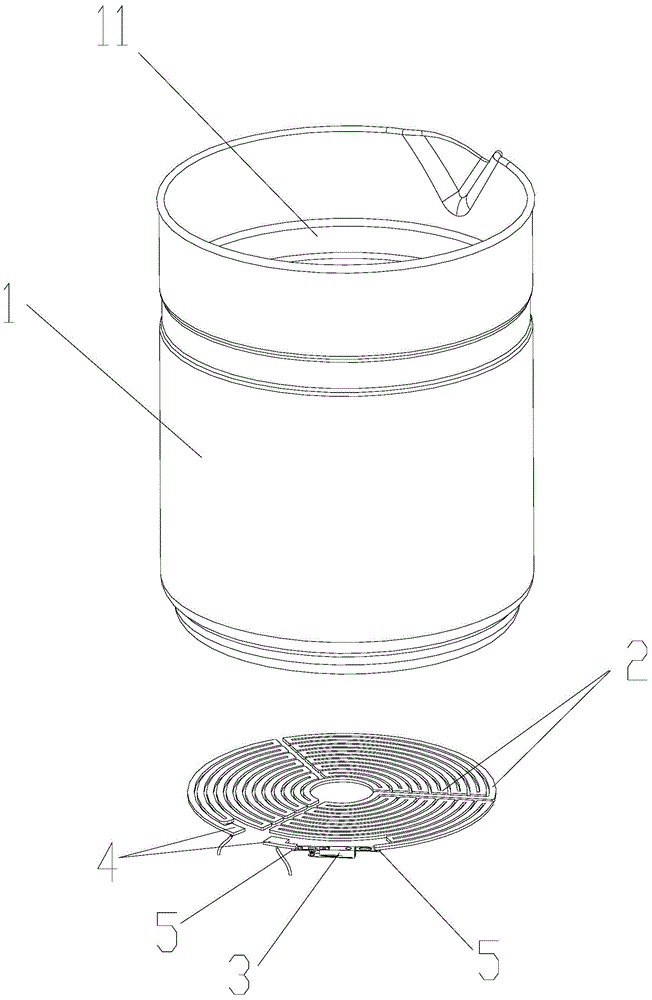

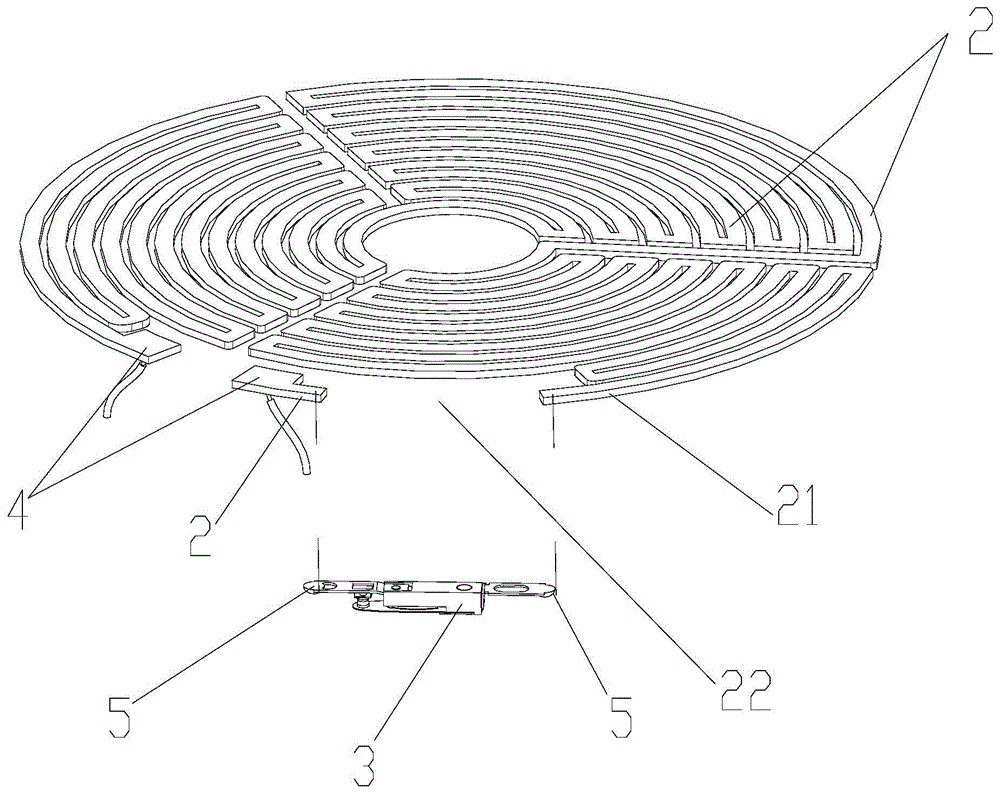

[0035] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, an anti-dry glass electric kettle includes a glass kettle body 1 and a far-infrared electric heating film 2. The glass kettle body 1 is provided with a water-holding cavity 11 inside, and the top is open. Outside the bottom surface of the glass kettle body 1 The surface mount far-infrared electric heating film 2 is characterized in that: it also includes a thermostat 3, and the thermostat 3 is mounted on the outer surface of the bottom surface of the glass pot body 1 and electrically connected in series with the far-infrared electric heating film 2. The thermostat 3 is a bimetal thermostat, and the far-infrared electric heating film 2 is formed by bending and spiraling a strip coating on the bottom surface of the glass jug body, and the thermostat 3 is arranged on the glass jug body The strip coating 21 on the outermost edge of the far-infrared electric heating film 2 on the outer s...

Embodiment 2

[0037] like Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the only difference is that the notch 22 is canceled, and an end of the strip-shaped coating 21 on the outermost edge of the far-infrared electric heating film 2 on the outer surface of the bottom outer surface of the glass jug body 1 The part is connected to one end of the thermostat 3 through soldering tin, and the other end of the thermostat 3 is connected to an electrode 4, and the other end of the strip-shaped coating 21 on the outermost edge of the far-infrared electric heating film 2 on the outer surface of the bottom of the glass jug body 1 The end is connected to another electrode 4 . Both ends of the thermostat 3 are connected through high temperature curing glue 6 . The two ends of the above-mentioned thermostat are connected through high-temperature curing glue. This connection is also relatively simple. There is no need to form a gap in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com