High efficiency energy saving multi-purpose furnace

A high-efficiency, energy-saving, multi-purpose furnace technology, applied in the field of multi-purpose furnaces, can solve the problems of unsuitable requirements, less food for one-time cooking, and low efficiency, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

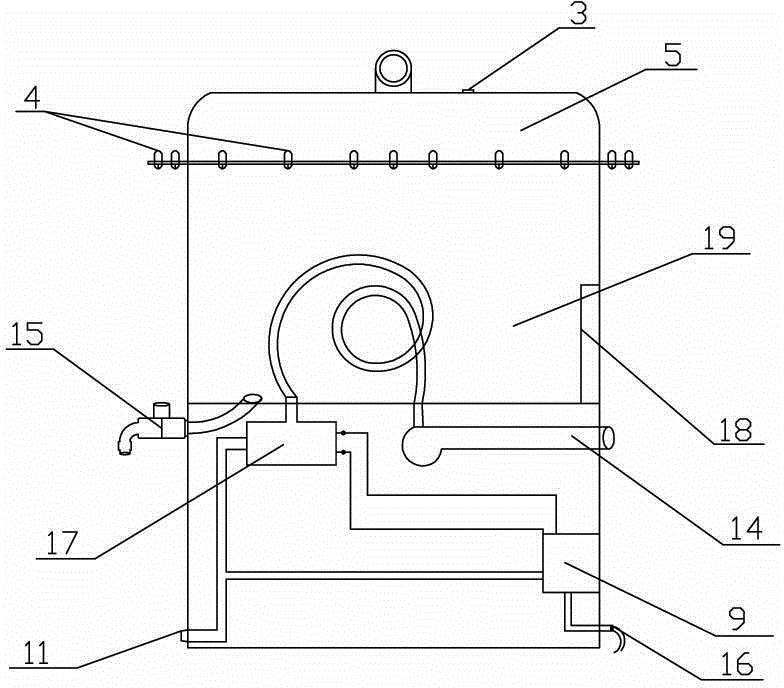

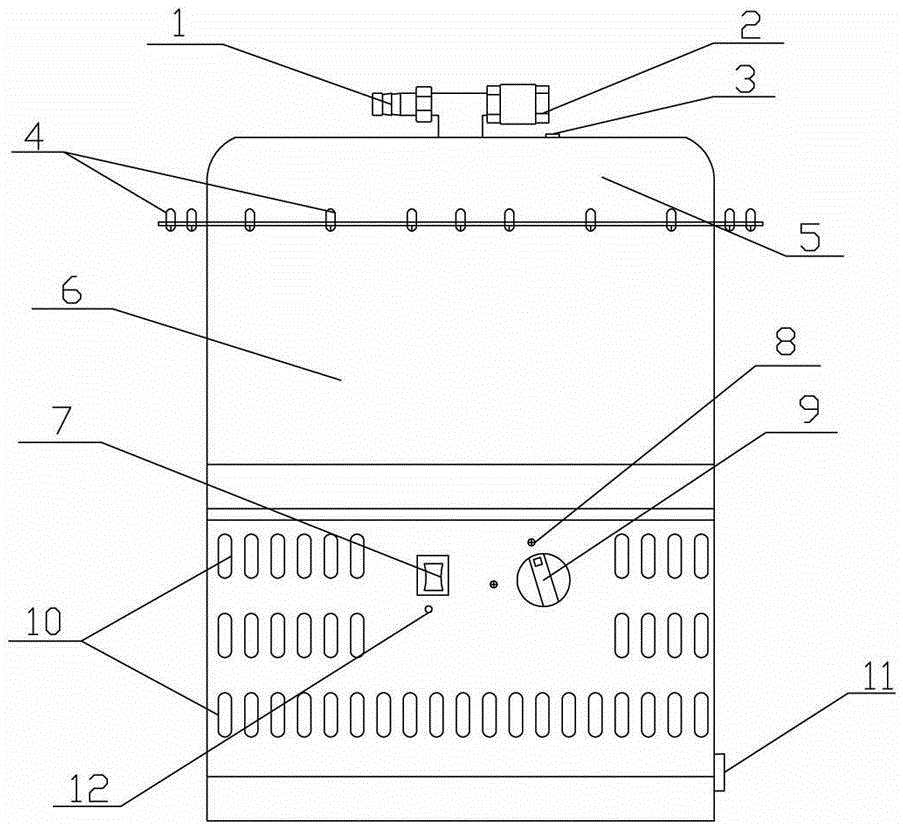

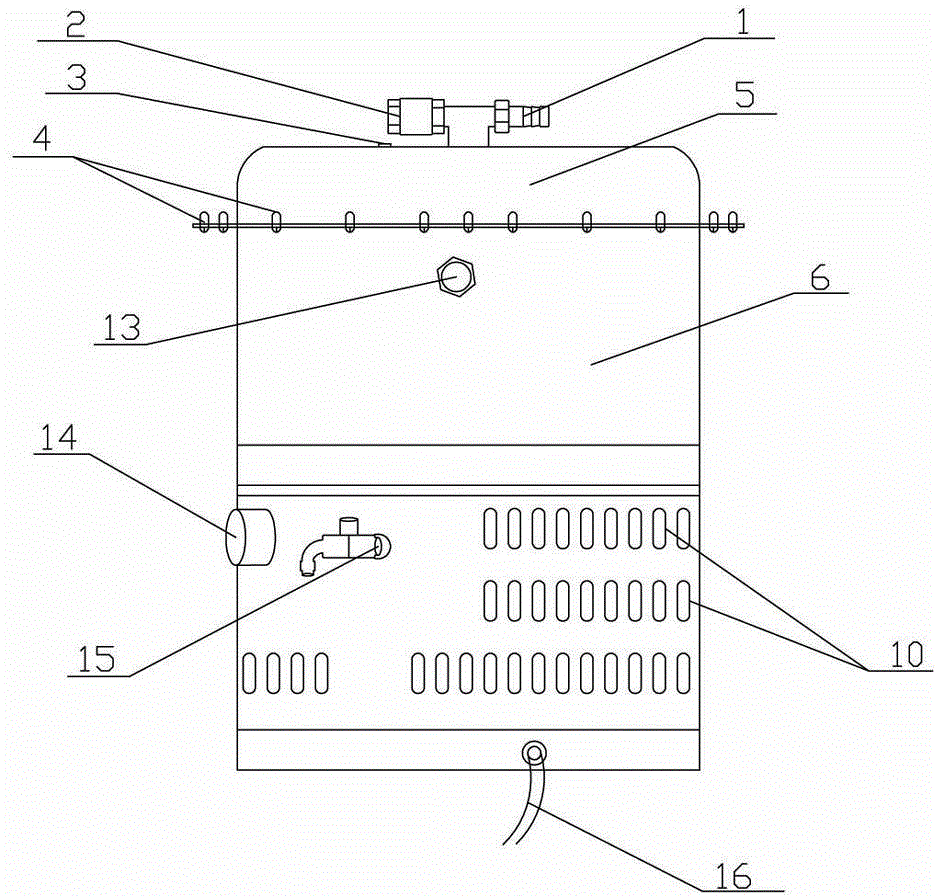

[0019] like Figure 1-3 As shown, a high-efficiency energy-saving multi-purpose furnace includes a stainless steel outer barrel (6), an inner barrel (19), a barrel cover (5), an air outlet (1), a water inlet (13), a water outlet (15), a safety pressure relief Valve (2), check valve (3), locking bolt (4), screw (8), fire suction fan (14), vent (10), water level sensor (18), overpressure switch (7), Liquefied petroleum gas inlet (11), indicator light (12), combustion tank (17), microcomputer ignition control (9) and power cord (16); the barrel cover (5) is locked on the On the stainless steel outer barrel (6); the water inlet (13) is installed on the upper end of the stainless steel outer barrel (6) to facilitate water intake; the microcomputer ignition control (9) is locked on the stainless steel outer barrel (6) through the screw (8), and the microcomputer An overpressure switch (7) is arranged next to the ignition control (9), and an indicator light (12) is arranged under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com