A new type of constant temperature material and its preparation method and application

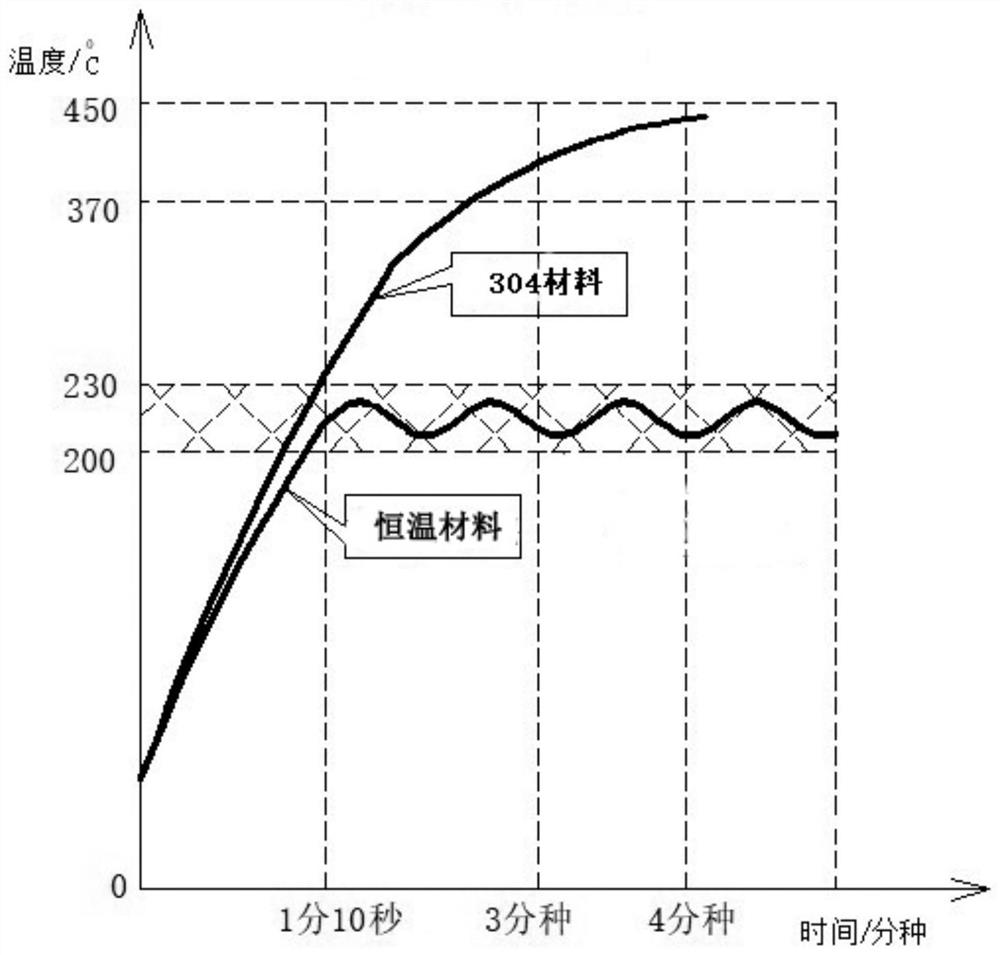

A constant temperature and new technology, applied in the field of new constant temperature materials and its preparation, can solve problems such as easy sticking to the pot, high toxicity, and rising temperature in the pot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

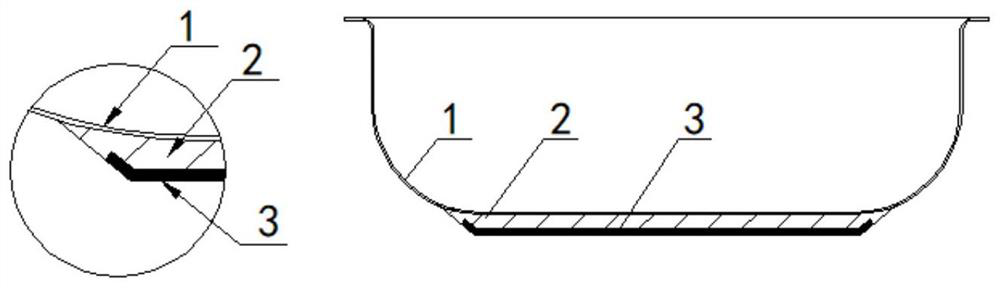

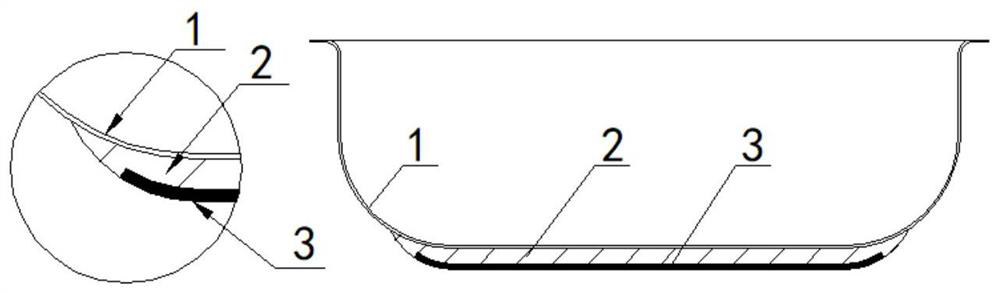

Image

Examples

Embodiment 1

[0026] (1) Material preparation

[0027] Taking the component composition of the new constant temperature material as a variable, this embodiment sets up group 4 treatment groups, which are respectively marked as treatment 1A group, treatment 1B group, treatment 1C group and treatment 1D group, calculated according to weight percentage, the corresponding group of each treatment group The grouping composition is shown in Table 1. In addition to the components listed in Table 1, the carbon content in the finished products produced by each treatment group is 0.005%–0.050%. In addition, the finished products produced by each treatment group also contain unavoidable impurities from raw materials. The impurities in the finished product corresponding to the treatment group all meet: phosphorus, P≤0.035%, sulfur, S≤0.018%.

[0028] The components corresponding to each treatment group in the present embodiment of table 1 are composed

[0029]

[0030]

[0031] (2) Preparation m...

Embodiment 2

[0043] (1) Material preparation

[0044] Taking the component composition of the new constant temperature material as a variable, this embodiment sets up group 4 treatment groups, which are respectively marked as treatment 2A group, treatment 2B group, treatment 2C group and treatment 2D group, calculated according to weight percentage, the corresponding group of each treatment group The grouping composition is shown in Table 2. In addition to the components listed in Table 2, the carbon content in the finished products produced by each treatment group is 0.005%–0.050%. In addition, the finished products produced by each treatment group also contain unavoidable impurities from raw materials. The impurities in the finished product corresponding to the treatment group all meet: phosphorus, P≤0.035%, sulfur, S≤0.018%.

[0045] The components corresponding to each treatment group in the present embodiment of table 2 are composed

[0046]

[0047] (2) Preparation method

[00...

Embodiment 3

[0059] (1) Material preparation

[0060] Taking the component composition of the new constant temperature material as a variable, this embodiment sets up group 4 treatment groups, which are respectively marked as treatment 3A group, treatment 3B group, treatment 3C group and treatment 3D group. Calculated according to weight percentage, the corresponding group of each treatment group The grouping composition is shown in Table 3. In addition to the components listed in Table 3, the carbon content in the finished products produced by each treatment group is 0.005%–0.050%. In addition, the finished products produced by each treatment group also contain unavoidable impurities from raw materials. The impurities in the finished product corresponding to the treatment group all meet: phosphorus, P≤0.035%, sulfur, S≤0.018%. 0–0.0012%, and the proportion of heavy rare earth elements is 0.0015–0.0025%.

[0061] The components corresponding to each treatment group in the present embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com