Production method of ready-to-eat canned abalone

A production method and technology of canned abalone, which is applied in the production field of instant canned abalone, can solve the problems of restricting the competition and development of the abalone processing industry, the decline in the quality of canned abalone, and poor taste, so as to facilitate industrial continuous production and reduce residual bacteria rate, the effect of retaining heat-sensitive nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

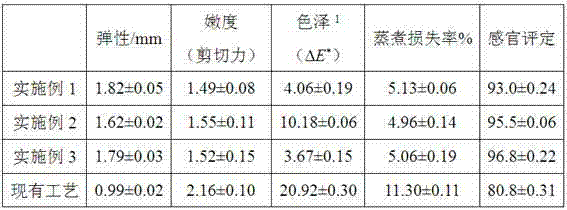

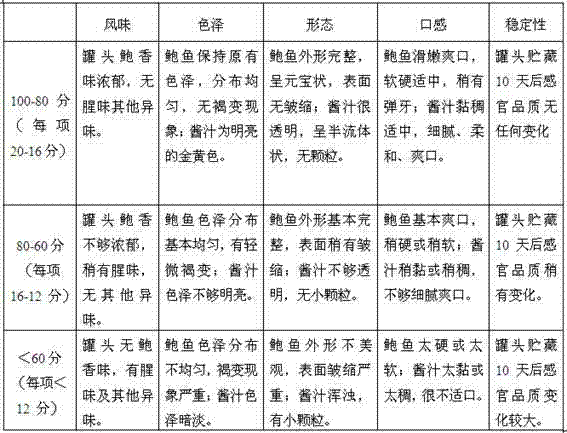

Examples

Embodiment 1

[0027] (1) Shelling and meat extraction: select fresh and live abalones that have grown for more than two years from the registered breeding base, are pollution-free, deformed, uniform in size, and weigh about 200 grams each, and use special tools to pick out the abalone meat and put it into a special-purpose abalone. Containers, intestinal glands and abalone shells should be removed in time;

[0028] (2) Drum washing with compound salt solution: transfer the abalone meat excavated in step (1) to the drum washing machine in time for rotating cleaning. / v, NaCl:CaCl 2 =3:2);

[0029] (3) Ultrasonic coupling hydrogen peroxide decontamination treatment: the abalone meat cleaned by the drum in step (2) is transported to the ultrasonic tank through the metal mesh belt, the ultrasonic power is 20kHz, and the ultrasonic intensity is 6W / cm 2 , the concentration of hydrogen peroxide in the water tank is 2g / L, the treatment is for 3 minutes, and the water temperature is controlled at ...

Embodiment 2

[0035] (1) Remove the shell and take the meat: take out the fresh abalone that has been temporarily stored for 10 hours from the salt water holding tank with a water temperature of 20°C, use special tools to pick out the abalone meat, put it into a special container, and remove the intestinal glands and abalone shells in time;

[0036] (2) Drum cleaning with compound salt solution: transfer the abalone meat excavated in step (1) to the drum washing machine for rotating cleaning in time, the drum speed is 40rpm, the processing time is 20 minutes, and the cleaning solution is a salt solution with a concentration of 3% (w / v, NaCl:CaCl 2 =3:2);

[0037] (3) Ultrasonic coupling hydrogen peroxide decontamination treatment: the abalone meat after the drum cleaning in step (2) is transported to the ultrasonic tank through the metal mesh belt, the ultrasonic power is 20kHz, and the ultrasonic intensity is 4W / cm 2 , the concentration of hydrogen peroxide in the water tank is 3g / L, the...

Embodiment 3

[0043] (1) Remove the shell and take the meat: Take out the fresh abalone that has been temporarily stored for 8 hours from the salt water holding tank with a water temperature of 20°C, use special tools to pick out the abalone meat, put it into a special container, and remove the intestinal glands and abalone shells in time;

[0044] (2) Drum washing with compound salt solution: Transfer the abalone meat excavated in step (1) to the drum washing machine for rotating cleaning in time. w / v, NaCl:CaCl 2 =3:2);

[0045] (3) Ultrasonic coupling hydrogen peroxide decontamination treatment: the abalone meat cleaned by the drum in step (2) is transported to the ultrasonic tank through the metal mesh belt, the ultrasonic power is 20kHz, and the ultrasonic intensity is 6W / cm 2 , the concentration of hydrogen peroxide in the water tank is 3g / L, the treatment is for 3 minutes, and the water temperature is controlled at 4-6°C;

[0046] (4) Rinsing and canning: put the abalone meat treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com