A kind of preparation method and use of mixed dairy enzymolysis product

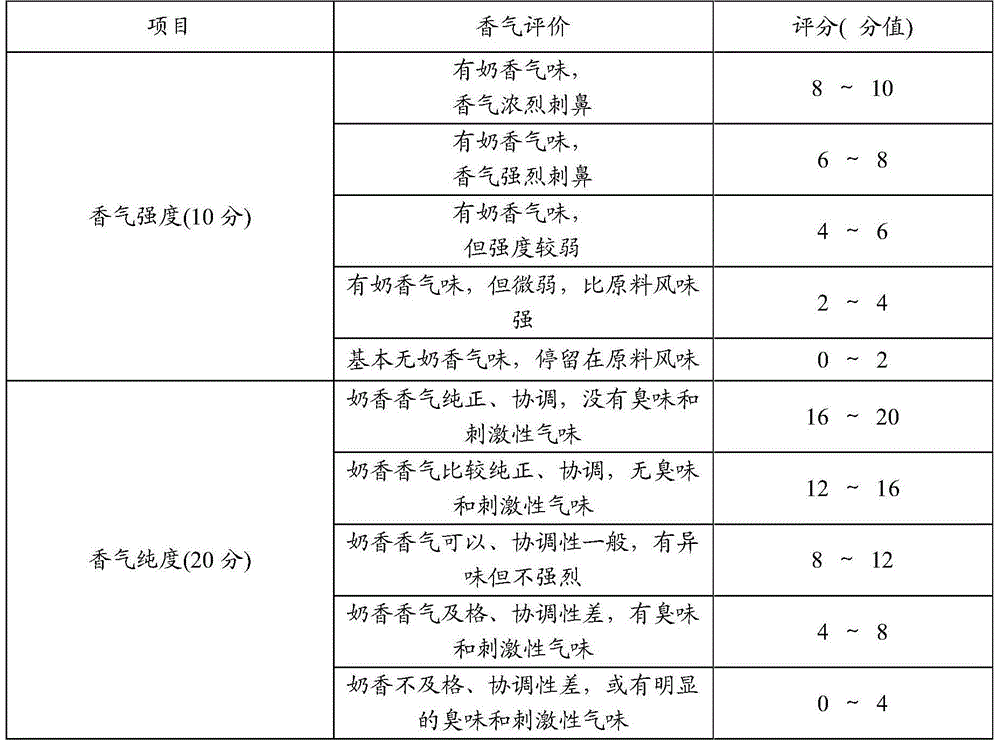

A technology of enzymatic hydrolysis products and dairy products, which is applied in food preparation, application, food science, etc., can solve the problems of low yield, weak aroma and unnatural aroma of single enzymatic cheese, achieve rich aroma, enhance milk aroma, improve The effect of fullness and roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

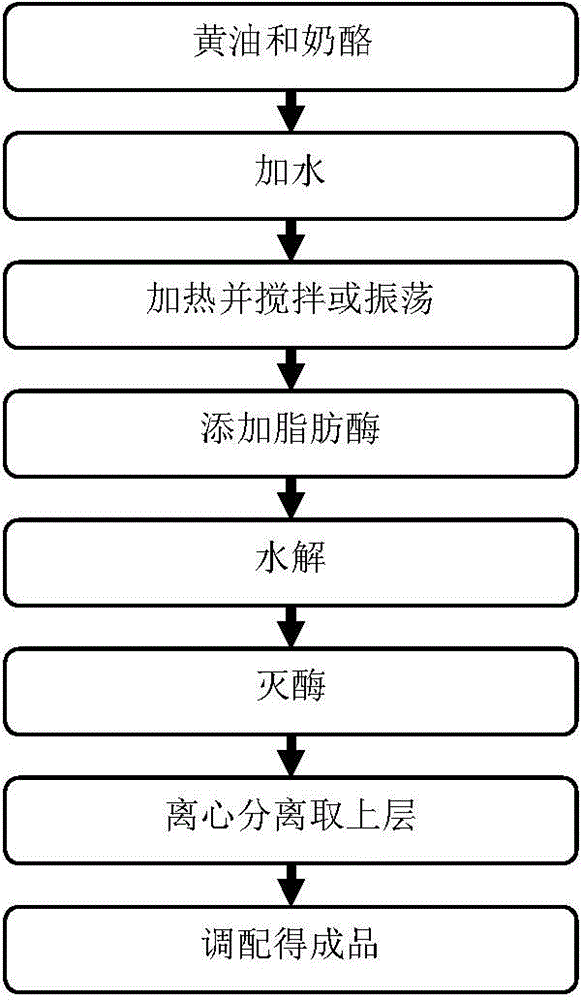

Method used

Image

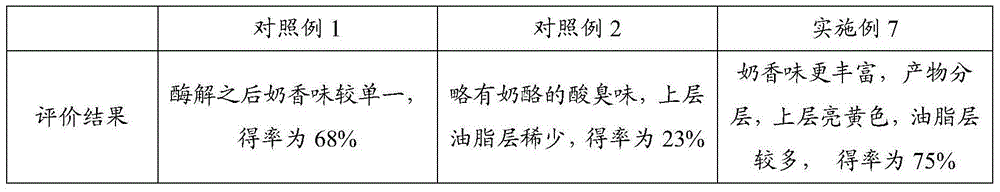

Examples

Embodiment 1

[0030] 1. Butter and cheese sterilization: Butter (fat content 85%) and cheese (fat content 25%) are fully mixed at a mass ratio of 1:1, the mass ratio of butter and cheese to water is 1:1, and the pH is adjusted to 7.50. Sterilize at 85°C for 15 minutes and cool down to 40°C.

[0031] 2. The lipase 1 with an enzyme activity of 10000 LU / g and the mixture of sterilized butter and cheese obtained in step 1 were mixed and stirred for 10 minutes to make them evenly mixed, wherein the lipase 1 accounted for 0.5% of the mass of the mixture.

[0032] 3. Shaking hydrolysis: 40°C, shaking speed 180r / min, reaction time 3h, end point pH 6.50.

[0033] 4. Enzyme inactivation: Boil at 100° for 5 minutes.

[0034] 5. Centrifugal separation: separate the water phase from the oil phase, and take the upper organic phase (the obtained organic phase, hereinafter referred to as the enzymatic hydrolysis product).

[0035] 6. According to 2.0 parts of diacetyl, 0.01 parts of 2-nonanedione, 1.0 pa...

Embodiment 2

[0037]1. Butter and cheese sterilization: butter (fat content 70%) and cheese (fat content 20%) are fully mixed at a mass ratio of 10:1, the mass ratio of butter and cheese to water is 8:1, and the pH is adjusted to 7.00. Sterilize at 85°C for 15 minutes and cool down to 35°C.

[0038] 2. The lipase 1 with an enzyme activity of 10000 LU / g and the mixture of sterilized butter and cheese obtained in step 1 were mixed and stirred for 10 minutes to make them evenly mixed, wherein lipase 1 accounted for 2.0% of the mass of the mixture.

[0039] 3. Oscillation hydrolysis: 35°C, oscillation speed 100r / min, reaction time 5h, end point pH 4.50.

[0040] 4. Enzyme inactivation: boil at 100°C for 5 minutes.

[0041] 5. Centrifugal separation: separate the water phase and the oil phase to obtain the upper organic phase (the obtained organic phase, hereinafter referred to as the enzymatic hydrolysis product).

[0042] 6. According to 0.8 parts of diacetyl, 0.05 parts of 2-nonanedione, 0....

Embodiment 3

[0044] 1. Butter and cheese sterilization: butter (fat content 60%) and cheese (fat content 30%) are fully mixed at a mass ratio of 8:1, the mass ratio of butter and cheese to water is 5:1, and the pH is adjusted to 7.80. Sterilize at 85°C for 15 minutes and cool down to 50°C.

[0045] 2. The lipase 1 with an enzyme activity of 10000 LU / g and the mixture of sterilized butter and cheese obtained in step 1 were mixed and stirred for 10 minutes to make them evenly mixed, wherein lipase 1 accounted for 1.5% of the mass of the mixture.

[0046] 3. Oscillation hydrolysis: 50°C, oscillation speed 300r / min, reaction time 2h, end point pH 6.90.

[0047] 4. Enzyme inactivation: boil at 100°C for 5 minutes.

[0048] 5. Centrifugal separation: separate the water phase and the oil phase to obtain the upper organic phase (the obtained organic phase, hereinafter referred to as the enzymatic hydrolysis product).

[0049] 6. According to 0.7 parts of diacetyl, 0.04 parts of 2-nonanedione, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com