Mounting for a pipeline

A technology for fluid pipelines and components, applied in the field of connecting devices on motor vehicle components, can solve problems such as production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

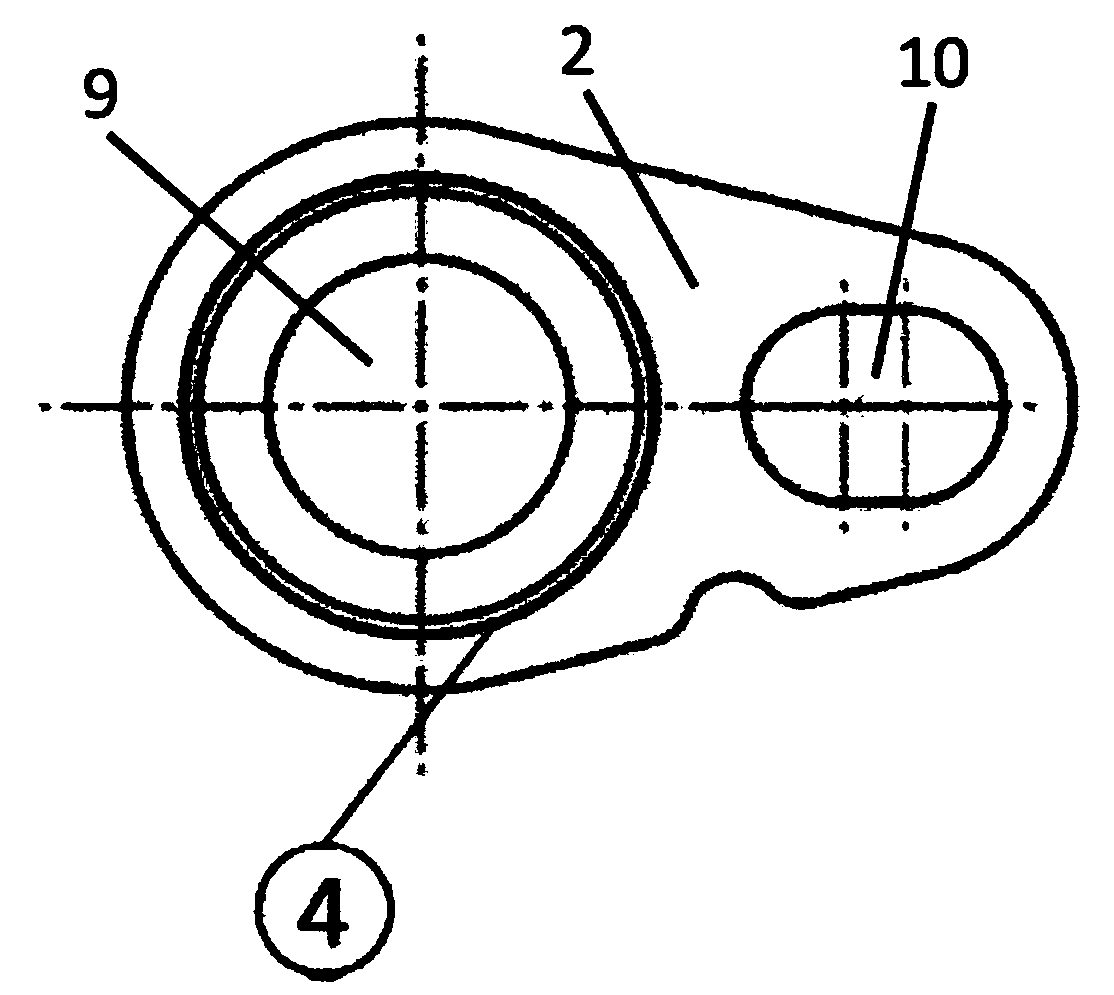

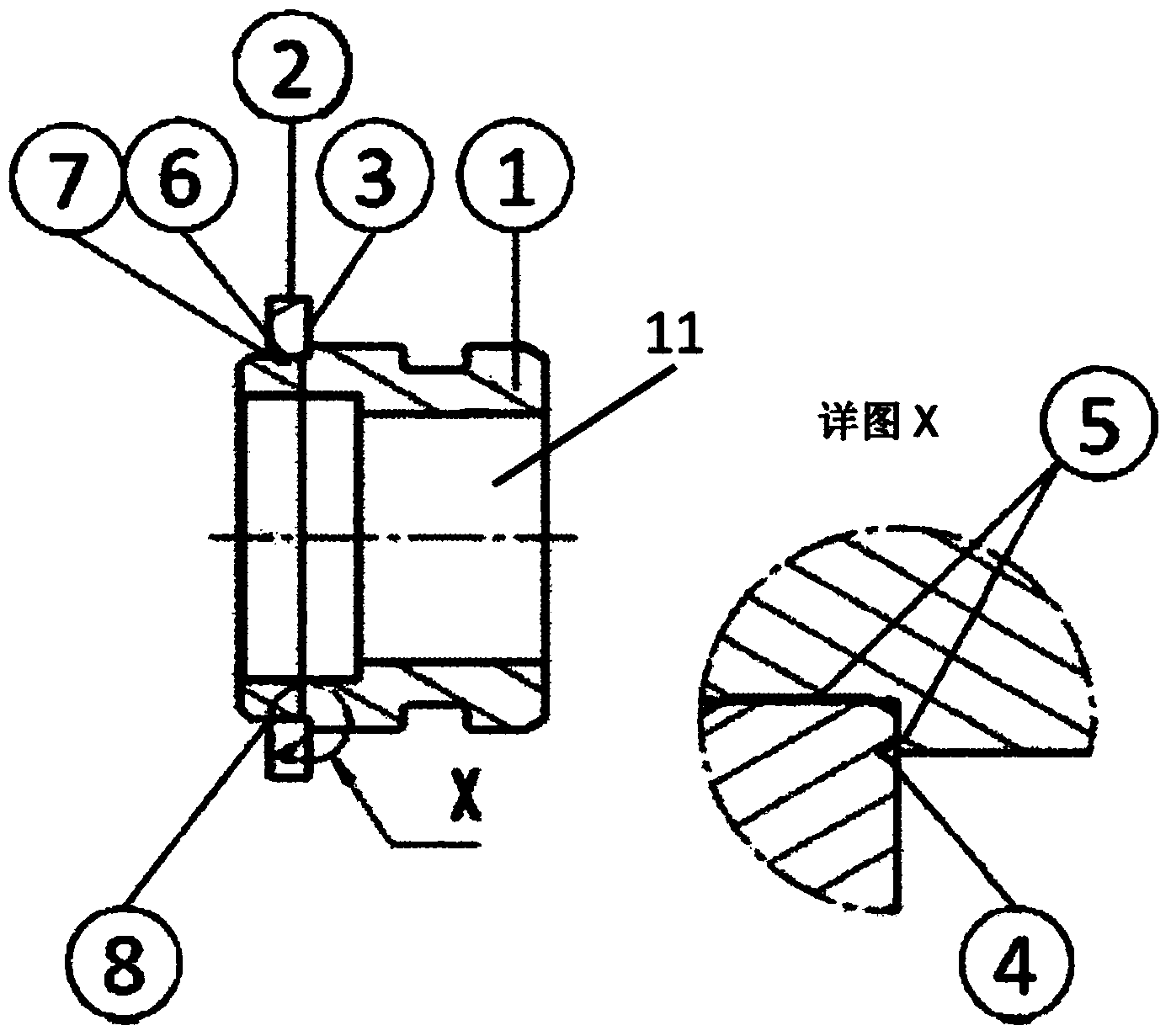

[0016] figure 1 A diagrammatic plan view of one flange 2 is shown. Flange 2 has a stub 1 for receiving (see figure 2 ) of a first opening 9 . Correspondingly, the inner diameter of the first opening 9 (bore 6, see figure 2 ) at least radially slightly larger than (connection diameter 7, see figure 2 ) the outer diameter of the stud 1 in the region 3 in which the flange 2 is to be inserted onto the stud 1 (insertion region 3).

[0017] Furthermore, the flange 2 has a second opening 10 . Through this second opening 10 the flange 2 and thus also the entire mounting device can be screwed onto a component, for example, in order to produce a fixed and fluid-tight connection between the component and a fluid line.

[0018] According to the invention, the flange 2 has a recess 4 which is preferably configured as a relief groove 4 . Said groove 4 extends radially on one face of the flange 2 around the first opening 9 . The groove 4 is configured and arranged on the flange 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com