Collector-electrode short-circuit IGBT structure integrating diode

A collector short-circuit and diode technology, which is applied in the direction of circuits, transistors, electrical components, etc., can solve the problems of increasing the packaging area and cost of diodes and IGBTs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

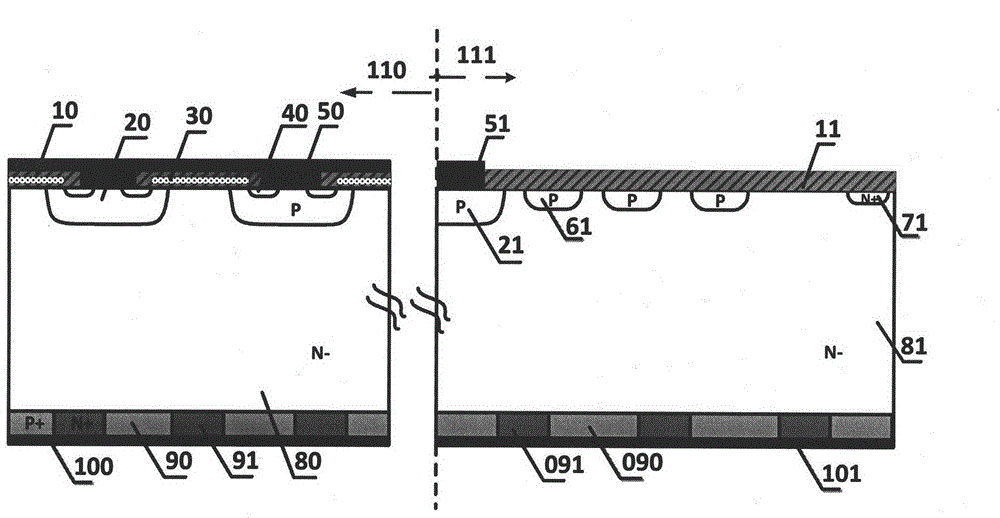

[0022] see image 3 , which shows a collector-short-circuit planar IGBT structure with integrated diodes, including a cell region (110) and a terminal region (111) surrounding the cell region (110), belonging to the technical field of power semiconductor devices. The cell region (110) includes an insulating layer (10), a polysilicon gate (30), an emitter metal (50), a P-body region (20), an emitter N + District (40), N - Drift region (80), collector P + region (90) and collector region (100); terminal region (111) includes main junction (21), field limiting ring (61), channel stop ring (71), N - Drift zone (81), N + Collector short-circuit region (91), emitter metal (51), collector metal (101) and insulating layer (11).

[0023] image 3 The structure shown is the same as figure 1 The structure shown differs in the size of the main junction area. image 3 The main junction area of the structure is large enough to make the current capacity of the integrated diode large...

Embodiment 2

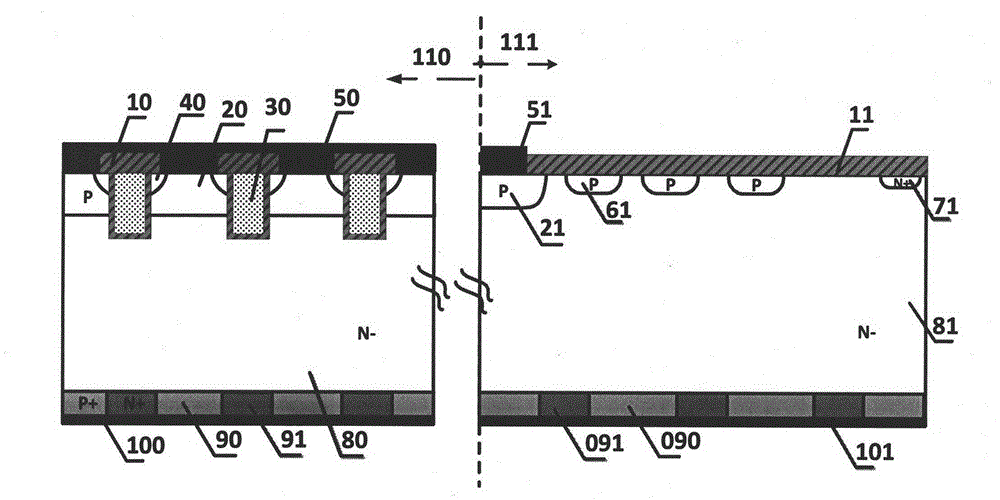

[0028] see Figure 4 , showing a collector-short-circuited trench-gate IGBT structure with integrated diodes, including a cell region (110) and a terminal region (111) surrounding the cell region (110), belonging to the technical field of power semiconductor devices . The cell region (110) includes an insulating layer (10), a polysilicon gate (30), an emitter metal (50), a P-body region (20), an emitter N + District (40), N - Drift region (80), collector P + region (90) and collector region (100); terminal region (111) includes main junction (21), field limiting ring (61), channel stop ring (71), N - Drift zone (81), N + An anode short circuit area (91), an emitter metal (51), a collector metal (101) and an insulating layer (11).

[0029] Figure 4 The structure shown is the same as figure 2 The structure shown differs in the size of the main junction area. Figure 4 The main junction area of the structure is large enough to make the current capacity of the integrat...

Embodiment 3

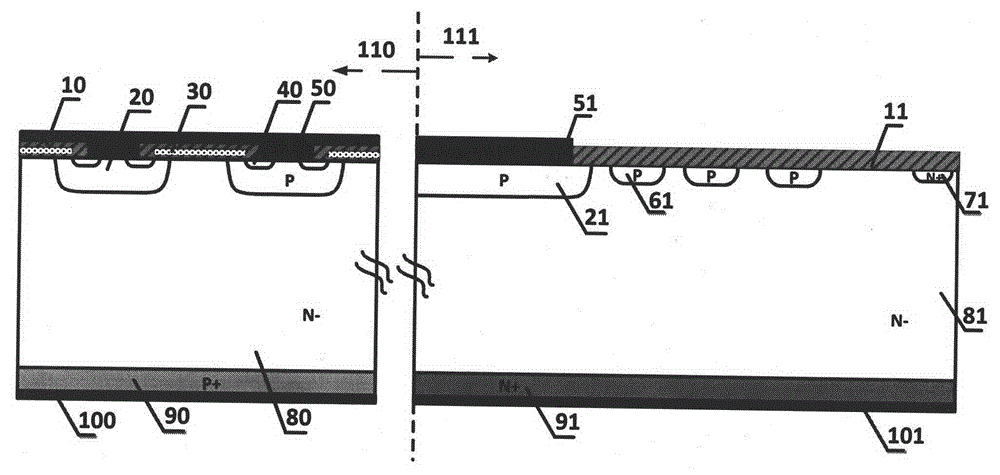

[0034] see Figure 5 , which shows a collector-short-circuited planar IGBT structure integrating JBS / MPS diodes, including a cell region (110) and a terminal region (111) surrounding the cell region (110), belonging to power semiconductor device technology field. The cell region (110) includes an insulating layer (10), a polysilicon gate (30), an emitter metal (50), a P-body region (20), an emitter N + District (40), N - Drift region (80), collector P + region (90) and collector region (100) termination region (111) including main junction (21), field limiting ring (61), channel stop ring (71), N - Drift zone (81), N + An anode short circuit area (91), an emitter metal (51), a collector metal (101) and an insulating layer (11).

[0035] Figure 5 The structure shown is the same as image 3 The difference in the shown structures is that the main junction structure is different, and the type of integrated diode formed is different. image 3 The structure adopts P-type ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com