A closed automatic flash point test system

A test system and closed technology, applied in the field of measuring instruments, can solve problems such as inaccurate test results, and achieve the effects of small rotor volume, good sealing performance, and shortened heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

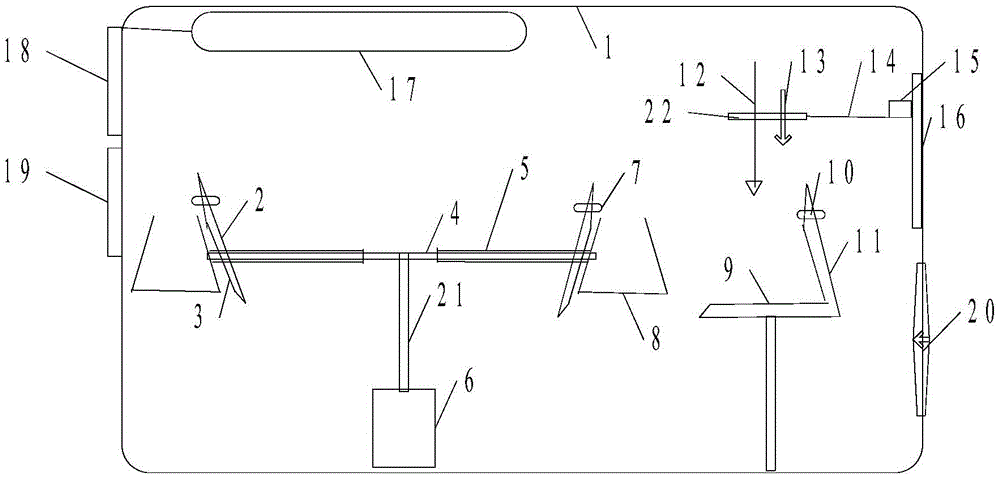

[0035] Such as figure 1 Shown, a kind of implementation mode of closed type automatic flash point test system of the present invention is:

[0036] Housing 1, at least one fan 20, which is arranged on the side wall of the housing 1, is electrically connected with the single-chip electromechanical device, and the control panel 18 and the liquid crystal display screen 19 are arranged on the front of the housing 1 on the outside.

[0037] A support structure, which includes a central shaft 21 and a plurality of connecting rods, the plurality of connecting rods are located on the same plane and radially distributed with the central shaft 21 as the center of a circle, and one end of the connecting rods is fixed on the central shaft 21 , the plane formed by the plurality of conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com