Electronic ignition weapon system

A weapon system, electronic ignition technology, applied in the field of weapons, can solve the problems of unpublished technical details, affecting accuracy, melting the barrel, etc., to achieve the effect of improving the resistance to voltage breakdown, being convenient to carry, and increasing combat effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

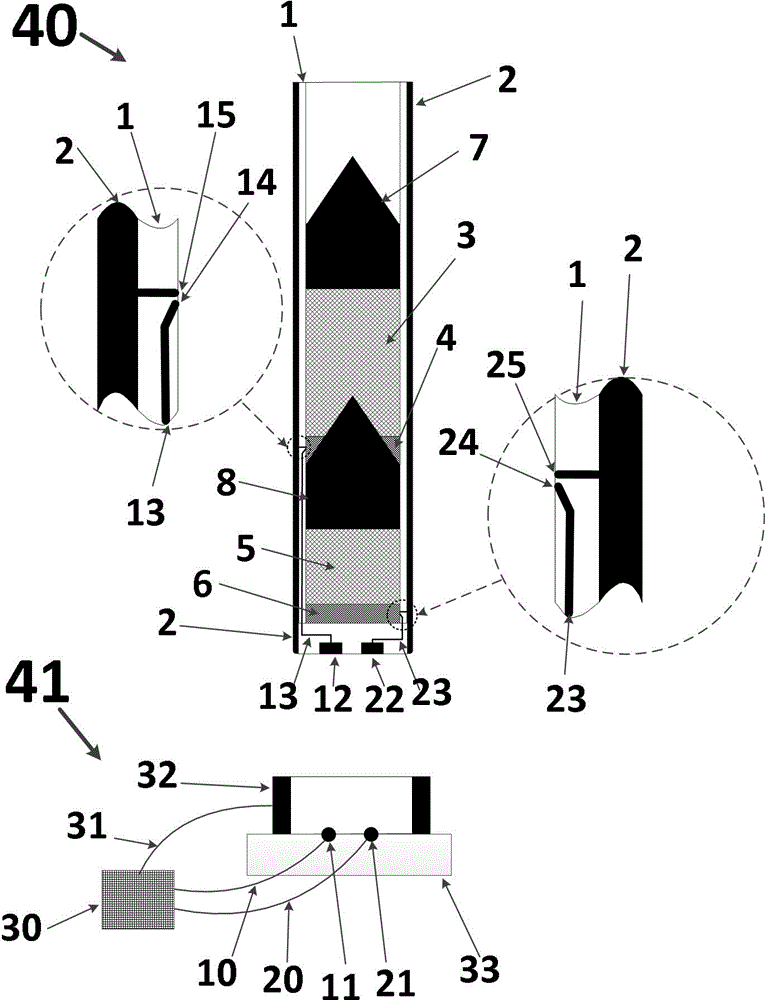

[0022] Such as figure 1 One of the present invention is the basic schematic diagram of the implementation example, which is a replaceable gun with a launch tube 40, two bullets are arranged in each tube, and special ceramics are used as the heat-resistant and wear-resistant insulating inner layer of the launch tube 40- That is, the ceramic inner layer 1 .

[0023] Such as figure 1 As shown, this embodiment is composed of a gun barrel 40 and a base 41, and the gun barrel 40 and the base 41 are detachably connected to facilitate replacement of the gun barrel.

[0024] Such as figure 1 Shown, gun barrel 40 is made of ceramic inner layer 1, metal outer layer 2, gunpowder 3, primer 4, gunpowder 5, primer 6, bullet 7, bullet 8, contact 12, wire 13, wire leakage point 14, metal outer layer Leak point 15, contact 22, wire 23, lead wire leak point 24, metal outer layer leak point 25 constitute.

[0025] Such as figure 1 As shown, the base 41 is composed of a control circuit 30 , a...

Embodiment 2

[0030] On the basis of implementing the principle of example 1, warheads are increased to seven.

[0031]

Embodiment 3

[0033] On the basis of implementing the principle of Example 2, a metal fusion bonding structure is set in the ignition area. When the bullet in this section is fired, the metal melting connects the corresponding wire of the bullet in this section to the outer layer of the metal to form a loop, so that the control circuit can judge the bullet. Whether the launch is successful, prevent the ignition of the rear section after the failure of the front section to cause the launch tube to explode.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com