Ribbed prestressed pipe pile, and manufacturing method and drilling-planting construction process thereof

A technology of prestressed pipe piles and construction technology, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems affecting the safe use of buildings, corrosion and damage of pipe pile joints, and reduced bearing capacity of prestressed pipe piles, etc., to achieve The quality of the pile connection is guaranteed, the corrosion damage is prevented, and the pile connection speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

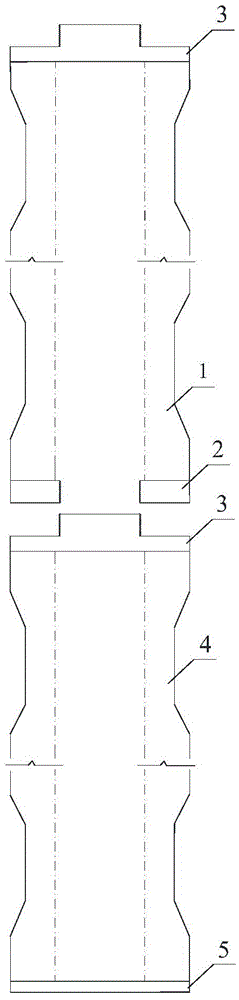

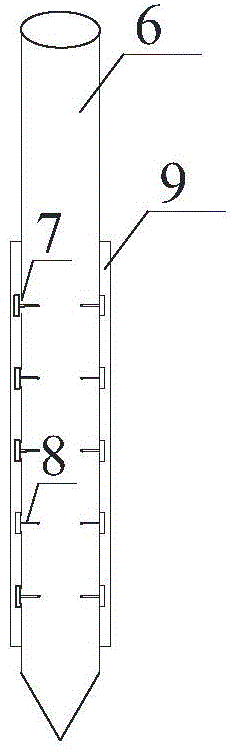

[0040] Such as Figure 1-2 As shown, the detailed drawing of the ribbed prestressed pipe pile connection includes the upper ribbed prestressed pipe pile 1, the end plate 2 with internal threads, the end plate 3 with external threads, and the internal thread of the end plate with internal threads Recessed threads, male threaded end plates with protruding male threads. The lower ribbed prestressed pipe pile 4 and the closed end plate 5. When the ribbed prestressed pipe pile is connected to the pile, fix the lower section of the ribbed prestressed pipe pile 4 with a clamp, rotate the upper section of the ribbed prestressed pipe pile 1, and place the upper section of the ribbed prestressed pipe pile 1 in the belt. The threaded end plate 2 is screwed into the externally threaded end plate 3 of the ribbed prestressed pipe pile 4 at the lower part. After correcting its verticality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com