An anchoring device for a wound composite carbon fiber plate

A carbon fiber plate and anchoring device technology, which is applied in bridge maintenance, bridge reinforcement, erection/assembly of bridges, etc., can solve the problems of high cost, bulky anchor body, inconvenient on-site construction operation, etc., so as to improve reliability and limit bearing capacity Ability, the effect of increasing anchoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

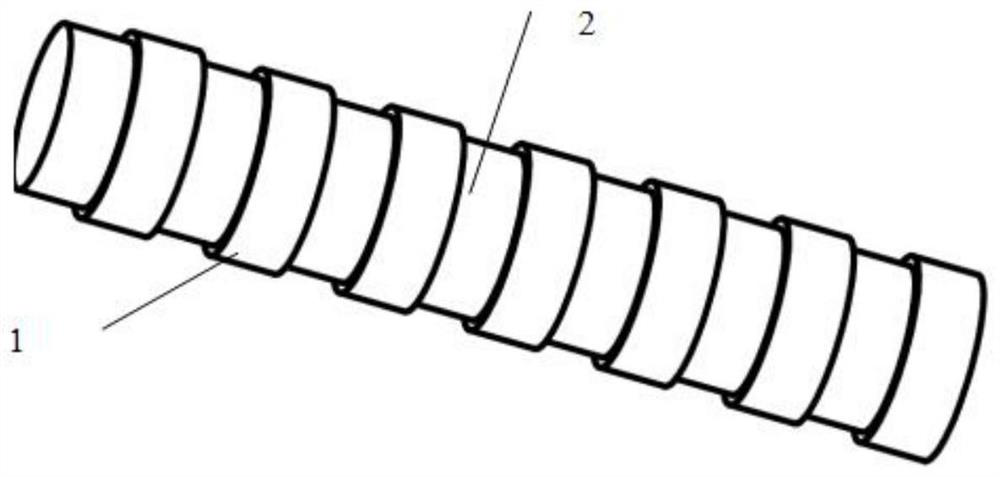

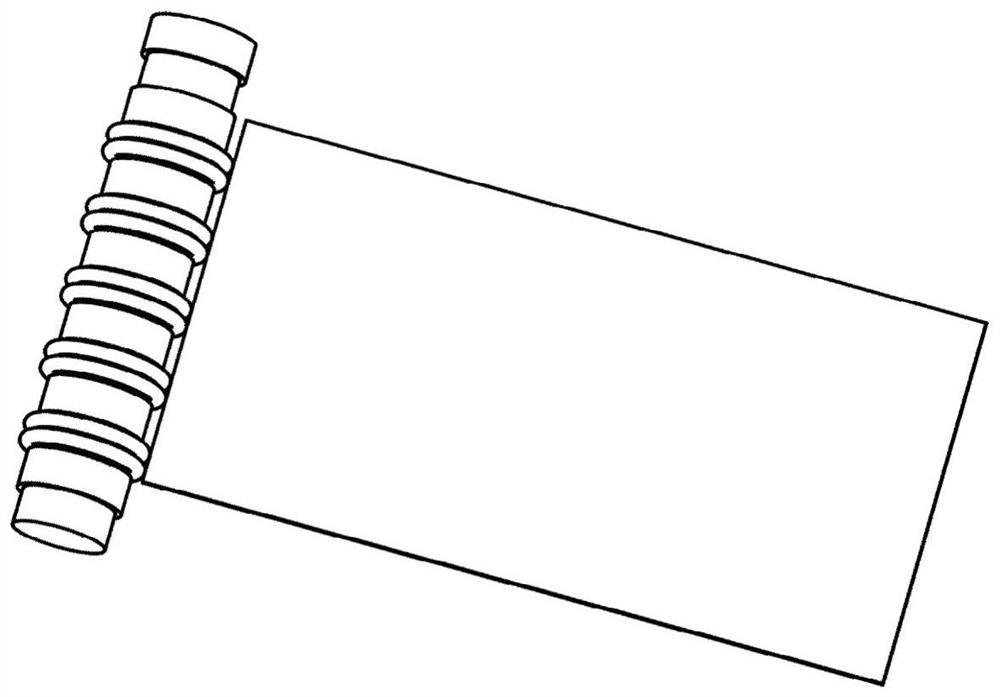

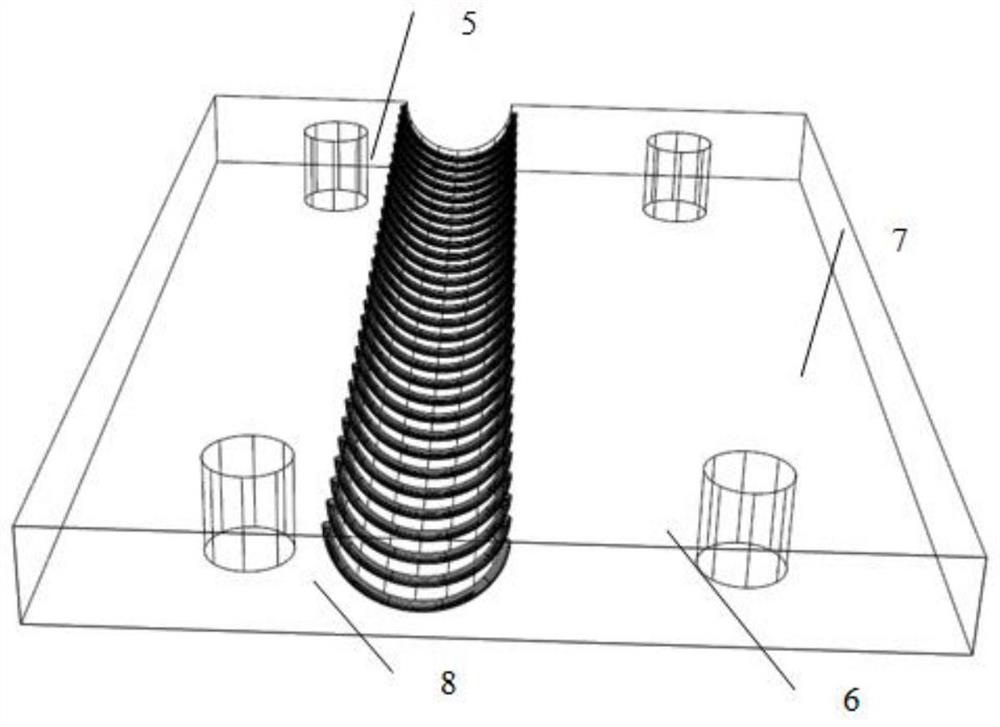

[0021] A winding composite carbon fiber plate anchoring device according to the invention. A groove with a diameter of 20-30 mm is prefabricated on the external structure groove-type steel plate 7 as the groove 5, and threads 8 are preset in the groove with a pitch of 1-2 mm. Bolt holes 6 are arranged on the slotted steel plate 7 . The internal structure is carbon fiber prepreg wound ribbed steel column, the diameter of the ribbed steel column is 20-30mm, and the rib depth is 1-1.5mm, the carbon fiber prepreg is wound on the steel column 1 with rib 2, and it is completed by heating solidify.

[0022] The specific implementation process is as follows:

[0023] The carbon fiber tow is passed through the dipping tank, the colloid fully infiltrates the carbon fiber tow, and the excess colloid is squeezed out by arranging a template with a certain aperture to form a carbon fiber prepreg. A certain force is applied to wind the carbon fiber prepreg on the steel column 1 with ribs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com