Lossless automated carbon change system and control method

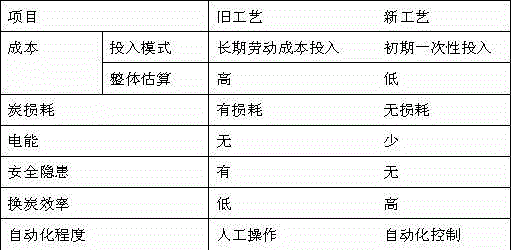

A lossless, sealed tank technology, applied in the direction of improving process efficiency, etc., can solve the problems of high labor intensity, increased adsorption burden, and potential safety hazards, and achieve the effects of high automation, shortening the time of carbon addition, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

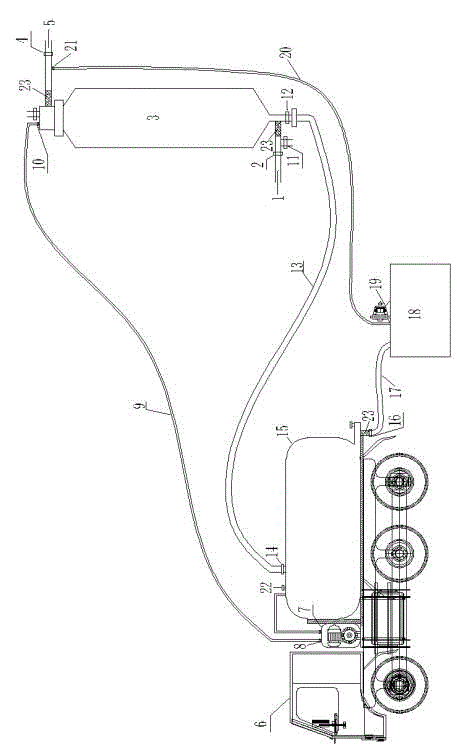

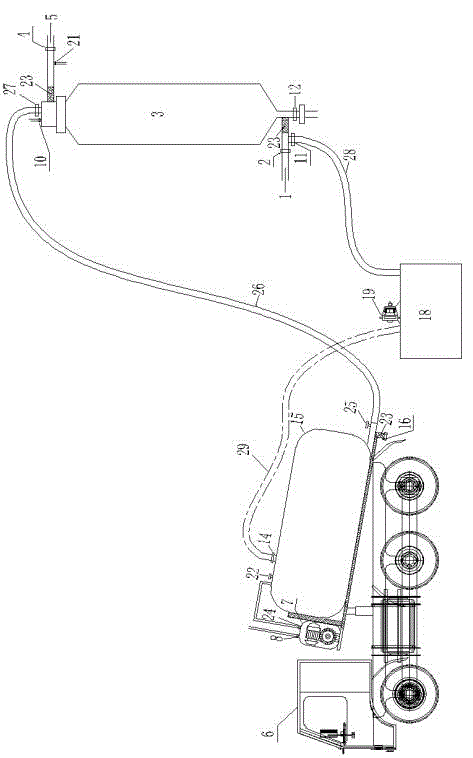

[0028] The non-destructive carbon replacement system includes carbon replacement vehicle 6, pressurization equipment 7, sealed tank 15, magnetic pump 19, transfer tank 18, adsorption column 3, as well as the input and output ports of the above components, transmission pipelines and corresponding control valves. The sealed tank 3 is placed on the carbon changing vehicle 6, the magnetic pump 19 is connected to the transfer tank 18, and the pressurizing equipment 7 is connected to the sealed tank 15 through pipelines; the sealed tank has a sealed tank carbon inlet 14, a sealed tank air inlet 24, and a sealed tank Outlet 16, adsorption column 3 has expensive liquid inlet 1, adsorption column carbon outlet 12, adsorption column carbon inlet 27, adsorption column filter water outlet 11, adsorption column air inlet 10, poor liquid outlet 5; Such as figure 1 As shown): Connect the carbon discharge air outlet 8 with the air inlet 10 of the adsorption column with the transmission pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com