Method for producing mevalonic acid by using grease as raw material, and gene engineering bacterium constructed by same

A technology for producing mevalonate and mevalonate, applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve problems such as low conversion rate, limited commercial application, etc. The effect of improving economy and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

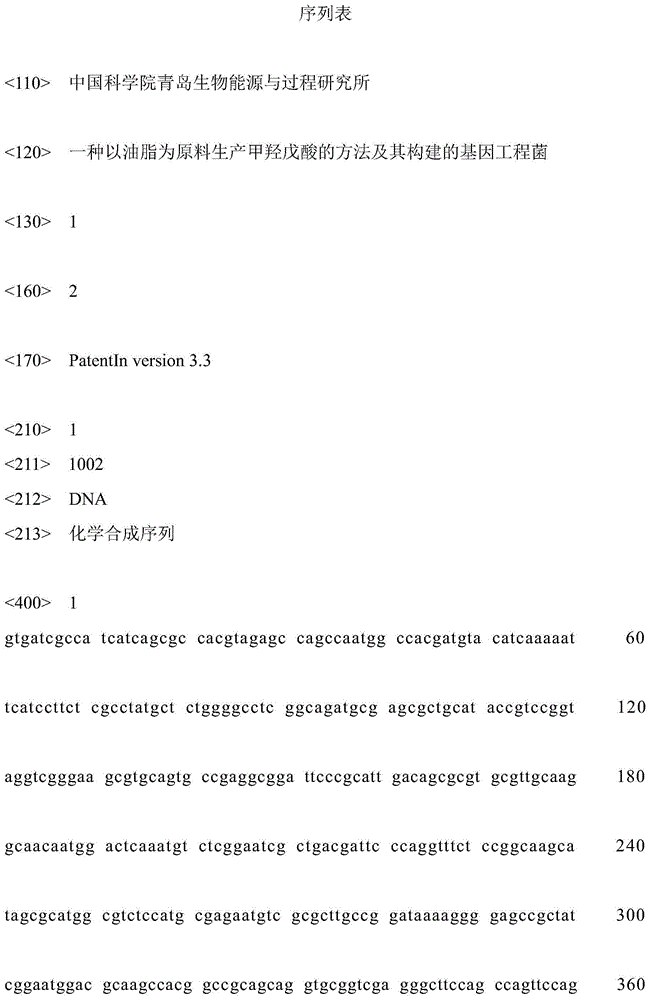

[0028] Example 1: Genetic modification of the genome of Alcaligenes eutropha H16, ie knockout of the phaC1 gene.

[0029] Knockout of the phaC1 gene . Alcaligenes eutropha Ralstonia eutropha H16 (from the German Culture Collection of Microorganisms, accession DSM428) was used as a basic strain for further genetic modification. According to the published genome information of Alcaligenes eutropha Ralstonia eutropha H16 (NCBI accession number: NC_008313.1), find phaC1 gene (NCBI accession number is NC_008313.1 Locus tag number in the genome: H16_A1437) each 500 bases upstream and downstream The gene sequence was merged into a 1,000-base sequence, and a linear DNA fragment (SEQ ID NO.1) of about 1,000 bases was chemically synthesized according to the sequence information. Both ends of the sequence contained 15 bp homology arms identical to those of the plasmid pJQ200mp18Km. The general suicide plasmid pJQ200mp18Km (York et al., 2001 Journal of Bacteriology 183:2394, provided by...

Embodiment 2

[0030] Example 2: Construction and engineering of Alcaligenes eutropha with expression vectors containing exogenous hydroxymethylglutaryl-CoA (HMG-CoA) synthetase genes and hydroxymethylglutaryl-CoA reductase genes build.

[0031] According to the published full-length sequence information of Enterococcus faecalis hydroxymethylglutaryl-CoA (HMG-CoA) synthetase gene and hydroxymethylglutaryl-CoA reductase gene (Tabata et al., 2004 Biotechnology Letters, 26:1487-1491), optimized the two sequences to be suitable for expression in Alcaligenes eutropha, and the optimized sequence was mvaZ1. Carry out chemical synthesis according to mvaZ1, add 15 bp homologous arm sequence identical with plasmid pBBR1MCS-2 to the two ends of the sequence respectively during synthesis. Then use the In-Fusion HD kit (Takara, Cat. No. 639648) to recombine the mvaZ1 fragment and the partial sequence of the universal expression plasmid pBBR1MCS-2 (Netherlands Culture Collection, No. NCCB3434) (without t...

Embodiment 3

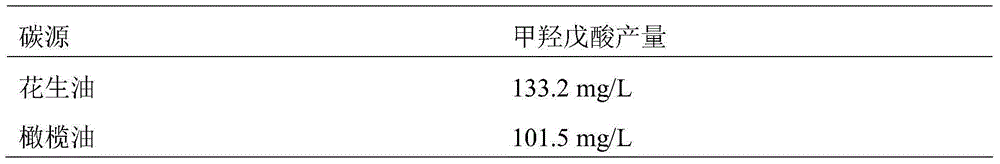

[0033] Example 3: Using the constructed engineered Alcaligenes eutropha to ferment and produce mevalonate with vegetable oil such as peanut oil or olive oil as carbon source.

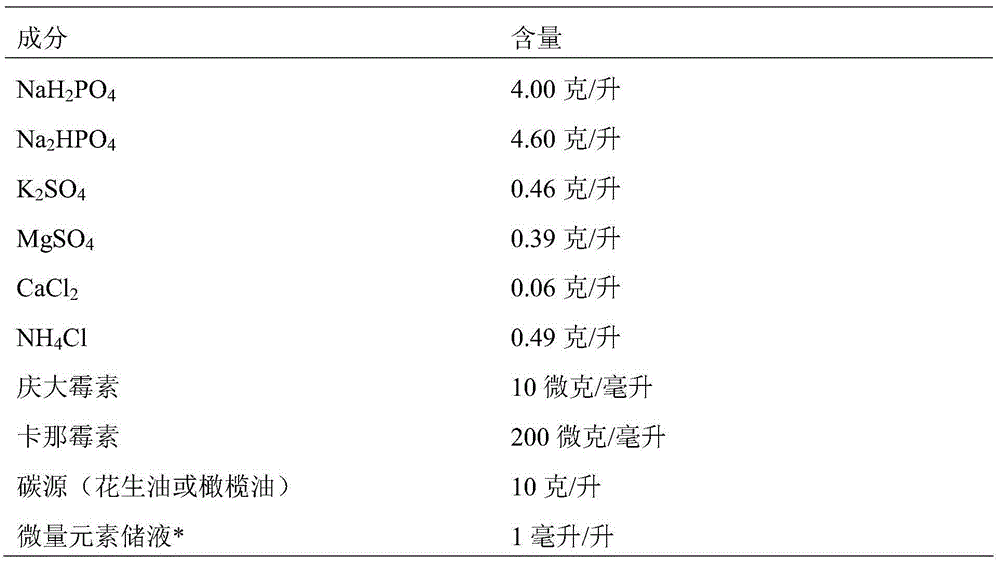

[0034]Using engineered Alcaligenes eutropha to ferment and produce mevalonate from vegetable oil (peanut oil or olive oil) as carbon source. The conditions for using this bacterial strain to ferment mevalonate are: use 100 ml liquid volume in a 500 ml shake flask system, inoculum size 5%, fermentation temperature 30°C, pH value control at 6.8, medium components see Table 1, The initial vegetable oil addition amount is 10 g / L (peanut oil or olive oil), the stirring speed is 300 to 600 rpm, and the dissolved oxygen is controlled at 20% to 40%. After 96 hours of fermentation, different vegetable oils are used as carbon sources to ferment mevalonate The output is shown in Table 2.

[0035] Table 1 Engineering Alcaligenes eutropha fermentation medium composition table

[0036]

[0037] *The formula of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com