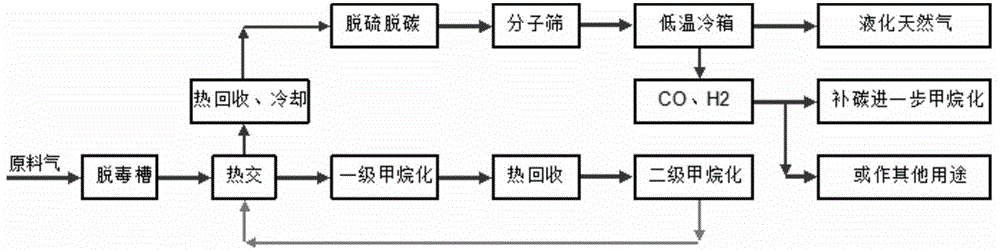

Production process of liquefied natural gas

A technology for liquefied natural gas and production process, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problem of unreported sulfur-resistant methanation production process, achieve significant energy-saving effect, reduce production costs, and reduce equipment investment and expenses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The first level of sulfur resistance-methanation: coke oven gas with a CO dry basis content of 8.5% first enters the detoxification tank to remove dust and other impurities, and then exchanges heat with the gas after the first-level methanation reaction to 450°C, and then enters the second-level The first-stage sulfur-resistant methanation reaction is carried out in one reactor. The hot spot temperature of the first-stage reactor bed is 650°C, the reaction pressure is 2.5MPa, and the dry basis content of CO in the outlet gas of the first-stage reactor is 4.1%; CH4 dry basis The content is 38.2%.

[0023] The gas after primary methanation is heat-exchanged with the coke oven gas at the inlet of the first-stage reactor, and the temperature is lowered to 450°C by the medium-pressure steam produced by the waste boiler, and enters the second-stage reactor for sulfur-resistant methanation reaction. The hot spot temperature of the first-stage reactor bed is 600°C, the dry basi...

Embodiment 2

[0027] The first level of sulfur resistance-methanation: the coke oven gas with a CO dry basis content of 9.0% first enters the detoxification tank to remove dust and other impurities, and then exchanges heat with the gas after the first-level methanation reaction to 450°C, and then enters the second-level The first-stage sulfur-resistant methanation reaction is carried out in one reactor. The hot spot temperature of the first-stage reactor bed is 650°C, the reaction pressure is 3.6MPa, and the dry basis content of CO in the outlet gas of the first-stage reactor is 3.6%; CH4 dry basis The content is 39.1%.

[0028] The gas after primary methanation exchanges heat with the inlet coke oven gas entering the first-stage reactor, and is cooled to 450°C by the medium-pressure steam produced by the waste boiler, and enters the second-stage reactor for sulfur-resistant methanation reaction. The hot spot temperature of the secondary reactor bed is 600°C, the dry basis content of CO at ...

Embodiment 3

[0032] The first level of sulfur resistance-methanation: the coke oven gas with a CO dry basis content of 10.1% first enters the detoxification tank to remove impurities such as dust, and then exchanges heat with the gas after the first-level methanation reaction to 450°C, and then enters the second-level The first-stage sulfur-tolerant methanation reaction is carried out in one reactor. The hot spot temperature of the first-stage reactor bed is 670°C, the reaction pressure is 2.5MPa, and the dry basis content of CO in the outlet gas of the first-stage reactor is 4.3%; CH4 dry basis The content is 38.1%.

[0033] The gas after primary methanation exchanges heat with the inlet coke oven gas entering the first-stage reactor, and is cooled to 450°C by the medium-pressure steam produced by the waste boiler, and enters the second-stage reactor for sulfur-resistant methanation reaction. The hot spot temperature of the secondary reactor bed is 600°C, and the dry content of CO and CH4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com