PA (Polyamide) 66/ASA (Acrylonitile) alloy material and preparation method thereof

An alloy material, PA66 technology, applied in the field of PA66/ASA alloy material and its preparation, can solve the problems of incompatibility between PA66 resin and ASA resin, ASA instability, etc., achieve strong dimensional stability, improve yield rate, and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

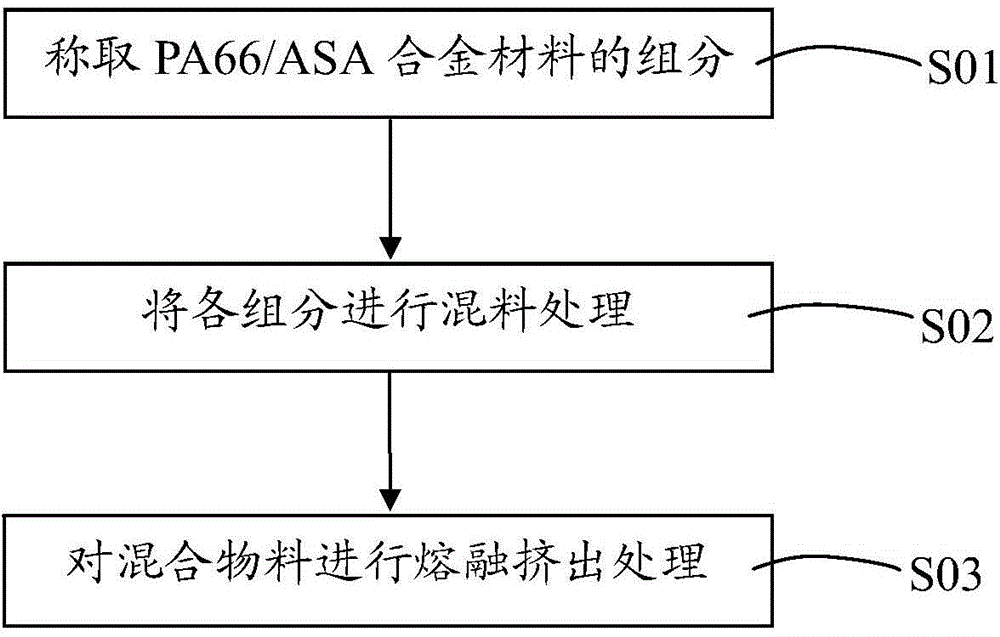

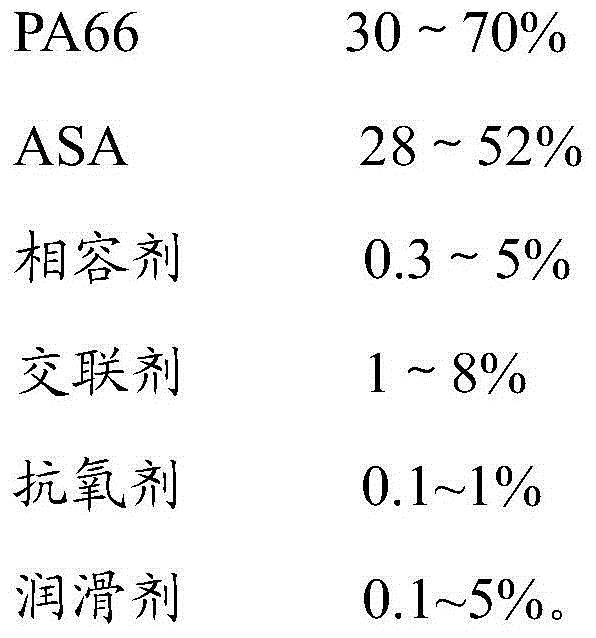

[0032] Correspondingly, the embodiment of the present invention also provides the preparation method of the above-mentioned PA66 / ASA alloy material, and its technological process is as follows figure 1 shown. The method includes the following steps:

[0033] S01. Weigh the components of the PA66 / ASA alloy material: weigh each component according to the formula of the above-mentioned PA66 / ASA alloy material;

[0034] S02. Perform mixing treatment on each component: perform mixing treatment on each component weighed in step S01 to obtain a mixed material;

[0035] S03. Melt-extrude the mixed material: melt-extrude the mixed material and granulate to obtain PA66 / ASA alloy material.

[0036] In the above step S02, the time for the mixing treatment is preferably 3-7 minutes, wherein the mixing treatment can be carried out in a medium-speed mixer, of course, it can also be carried out in other mixers, as long as the components are uniformly mixed .

[0037] In the above step S03...

Embodiment 1~8

[0042] The specific components by weight percentage of each PA66 / ASA alloy material in Examples 1-8 are shown in Table 1 below.

[0043] The preparation method of each PA66 / ASA alloy material in the above-mentioned embodiments 1-8 is the same, including the following steps:

[0044] S1. Weigh all the components of each PA66 / ASA alloy material in the above-mentioned embodiments 1 to 8 according to the specific proportions in Table 1;

[0045]S2. Mixing the above-mentioned dried components in a medium-speed mixer to obtain a mixed material;

[0046] S3. Extrude the mixed material in a twin-screw extruder with a melting temperature of 200-260° C., and granulate. Among them, the temperature of each section is: 200°C in the first zone, 240°C in the second zone, 250°C in the third zone, 255°C in the fourth zone, and 260°C in the fifth zone. The residence time of the mixed material in the screw is 90 seconds.

[0047] Table 1

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com