A kind of cross-linkable fluorosilicone resin and its preparation and application in super amphiphobic materials

A technology of fluorosilicone resin and super-amphiphobic, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of complex methods, complex processes, and cumbersome processing processes, and achieve simple preparation methods, The synthesis method is simple and the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

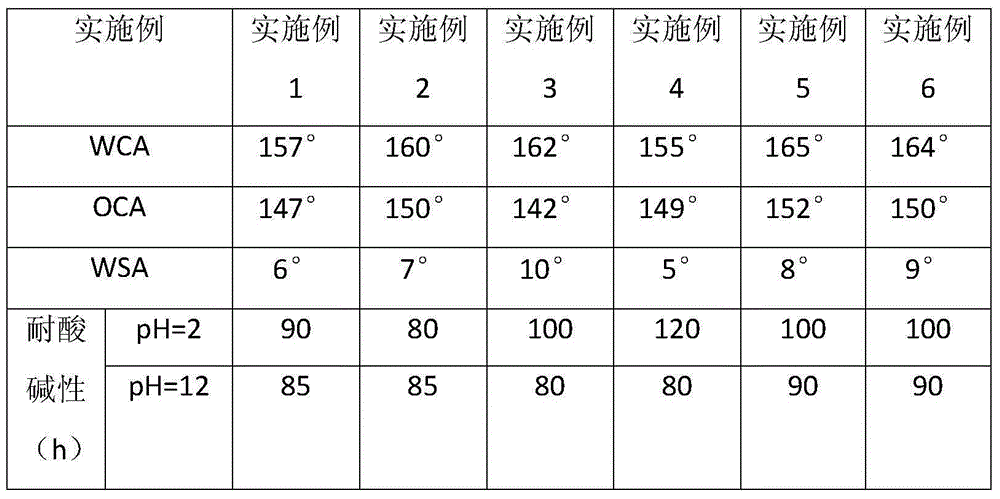

Examples

Embodiment 1

[0053] A preparation method of water-dispersible crosslinkable fluorosilicone resin comprises the following steps and process conditions thereof:

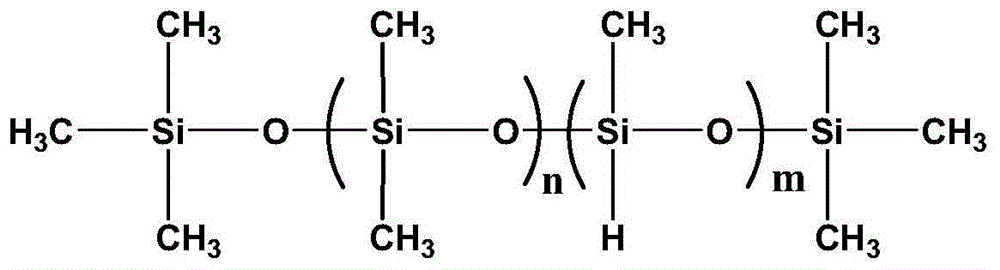

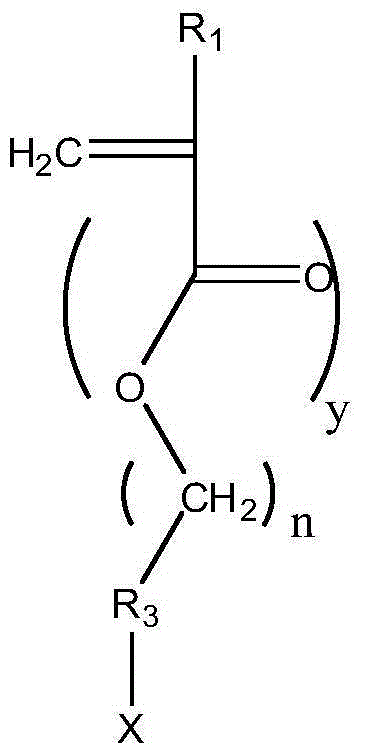

[0054] Step 1: Preparation of epoxy-containing silicone oil

[0055] Dissolve hydrogen-containing silicone oil, epoxy-containing monomer A with double bond and catalyst B in solvent C, and react under reflux and stirring for 4 hours at 60°C, cool to room temperature and concentrate, then add the concentrated solution to solvent D After precipitation and drying, the desired epoxy-containing silicone oil can be obtained.

[0056] Among them, the mass ratio between hydrogen-containing silicone oil, epoxy-containing monomer A with double bond, catalyst B and solvent C is 1:1:0.00001:10; the epoxy-containing monomer A with double bond is methyl Acrylic acid glycidyl ether; Catalyst B is chloroplatinic acid; Solvent C is toluene; Solvent D is methanol.

[0057] Step 2: Preparation of amphiphilic fluorosilicone resin

[0058] Dissolve ...

Embodiment 2

[0069] A preparation method of water-dispersible crosslinkable fluorosilicone resin comprises the following steps and process conditions thereof:

[0070] Step 1: Preparation of epoxy-containing silicone oil

[0071] Dissolve hydrogen-containing silicone oil, epoxy-containing monomer A with a double bond and catalyst B in solvent C, and react under reflux and stirring for 5 hours at 70°C. After cooling to room temperature, concentrate, and then add the concentrated solution to the solvent In D, the desired epoxy-containing silicone oil can be obtained after precipitation and drying.

[0072] The mass ratio between hydrogen-containing silicone oil, epoxy-containing monomer A with double bond, catalyst B and solvent C is 1:5:0.00003:20; the epoxy-containing monomer A with double bond is acrylic Glycidyl ether; Catalyst B is chloroplatinic acid; Solvent C is cyclohexanone solvent; D is anhydrous ether.

[0073] Step 2: Preparation of amphiphilic fluorosilicone resin

[0074] D...

Embodiment 3

[0084] A preparation method of water-dispersible crosslinkable fluorosilicone resin comprises the following steps and process conditions thereof:

[0085] Step 1: Preparation of epoxy-containing silicone oil

[0086] Dissolve hydrogen-containing silicone oil, epoxy-containing monomer A with a double bond and catalyst B in solvent C, and react under reflux and stirring for 5 hours at 70°C, cool to room temperature and concentrate, then add the concentrated solution to solvent D After precipitation and drying, the desired epoxy-containing silicone oil can be obtained.

[0087] Wherein the mass ratio between hydrogen-containing silicone oil, epoxy-containing monomer A with double bond, catalyst B and solvent C is 1:20:0.0008:40; the epoxy-containing monomer A with double bond is 1, 2-epoxy-5-hexene; B is chloroplatinic acid; C is dimethylformamide; D is n-hexane.

[0088] Step 2: Preparation of amphiphilic fluorosilicone resin

[0089] Dissolve epoxy-containing silicone oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com