Tower-type bioreactor synchronously removing carbon, nitrogen and sulfur

A bioreactor and reactor technology, which is applied in the field of sulfur tower bioreactor, nitrogen, and carbon simultaneous removal, can solve the problem of single function and achieve the effect of low energy consumption and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

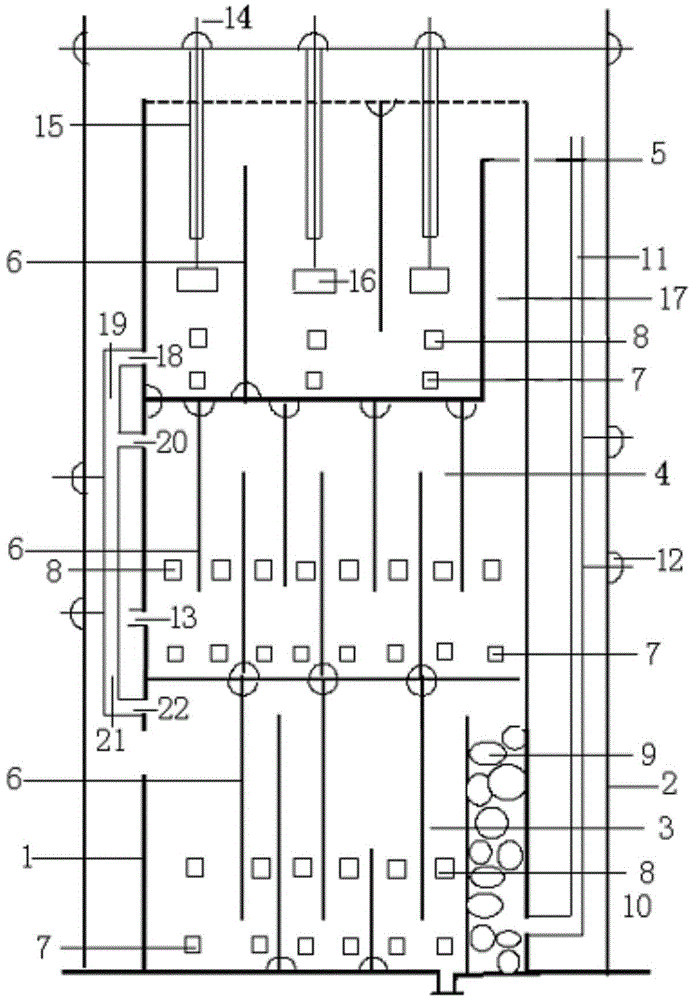

[0022] refer to figure 1 , a tower-type bioreactor for synchronously removing carbon, nitrogen, and sulfur, including a reactor body 1, a base, a vertical support 2 and a horizontal support, and the reactor body 1 and the vertical support 2 are fixed on the The two ends of the horizontal support are fixed on the vertical support 2, and the reactor body 1 is divided into anaerobic zone 3, anoxic zone 4 and aerobic zone from bottom to top. 5. The above-mentioned anaerobic zone 3, the anoxic zone 4 and the aerobic zone 5 are all provided with several baffles 6 and the several baffles 6 are arranged up and down; the anaerobic zone 3 1. The bottoms of the anoxic zone 4 and the aerobic zone 5 are respectively provided with mud outlets 7, and the middle and lower ends of the anaerobic zone 3, the anoxic zone 4 and the aerobic zone 5 are respectively provided with sampling ports 8;

[0023] The right side of the anaerobic zone 3 is provided with a packing bed 9, and the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com