Method for realization of nitrite accumulation during nitrate reduction process

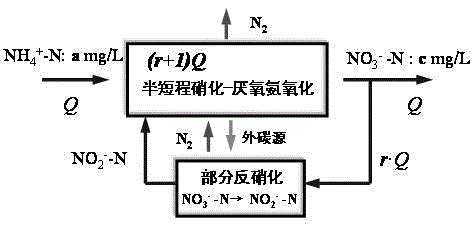

A nitrite and nitrate technology, applied in the field of water treatment, can solve problems such as difficulty in achieving deep denitrification, and achieve the effects of automatic program management, high denitrification rate, and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

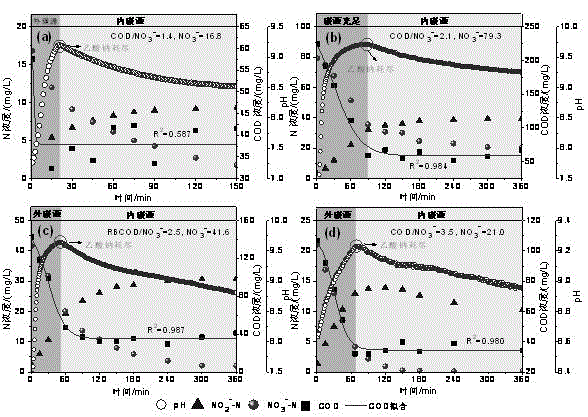

[0032] Attached below Figure 4 The actual operation effect describes the present invention in detail:

[0033] I. Selection of sludge type and concentration

[0034] The anoxic residual sludge in the anoxic / aerobic biofilm reactor with a sludge age of 40±2d was selected as the test sludge. Carry out 2.5 hours of aerobic aeration before the reaction starts, and place it for 2.5 hours, so that the microorganisms in the sludge are under the condition of non-nutritive substrate, then wash it with deionized water for 3 times, and place it in a sequencer with an effective volume of 3L. In the batch activated sludge reactor (SBR), the sludge concentration is set to 1200mg / L according to the volume of the reactor.

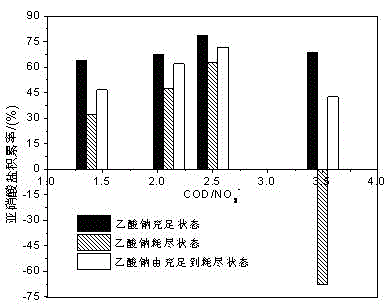

[0035] ii. Select carbon source and set carbon-nitrogen ratio

[0036] Sodium acetate was selected as the external carbon source. in NO 3 - During the -N reduction process, with the consumption of sodium acetate, a similar inflection point appeared on the pH curve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com